Information

Yanmar Releases a New Air-Conditioning Systems Series

May 27, 2015

Yanmar Co., Ltd.

Yanmar Energy System Co., Ltd. has announced the October 1, 2015 launch of a new series of energy efficient gas heat pump (GHP) *1 air-conditioning systems, the GHP XAIR II K. The series is the successor of the GHP XAIR series developed in 2011, and which at the time received high acclaim in the market for its energy-saving features and high performance.

With the amendment of the Energy Saving Act in Japan in April 2014, increased use of gas air-conditioning systems has been assertively promoted, along with stricter policies for the saving of energy. This represents a tremendous opportunity for Yanmar to provide the market with energy-saving products, and contribute to the popularization of gas powered equipment with decreased impact on the environment.

The design of the new series bears the signature of no other than world-renowned industrial designer, Ken Okuyama, who is also on the executive board of Yanmar Holdings Co., Ltd. Along with a premium design, the series features a significantly-improved annual operating efficiency as a result of a reduced number of revolutions in the gas engine and the optimization of the compressor.

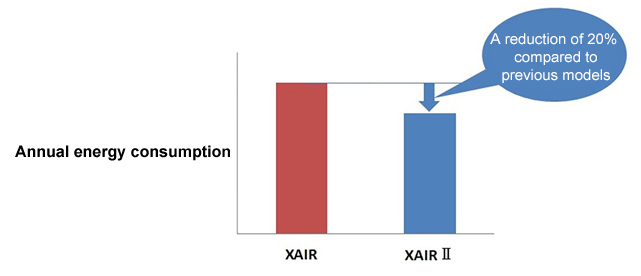

In addition, the models present an air-conditioning capacity ranging from 45 to 85kW (16~30Hp), representing an improvement of 24% on average in operating efficiency compared to the previous range, expected to yield an annual decrease in primary energy consumption of approximately 20%*2.

Making full use of its know-how and expertise in the domain, Yanmar will continue to assertively develop products of unrivalled quality and durability.

Core Features

1.Premium Design

The refined design confers a touch of class that harmoniously complements the innovative, eco-friendly feature of the series. The two-toned vertical lines in the four corners enhance the compactness of the product, while the external panel uses masked screws to optimize design. Due care has also been paid to easing handling and maintenance, with the net cover of the heat exchanger configured with a width that narrows down towards the base for enhanced safety.

2.Significant Improvement of Operating Efficiency

(1)Enhanced engine efficiency and reduced start-stop loss

Enhancing minimum engine revolution span from 650 to 500*4 times a minute made it possible to operate the product at low load (75%) *3 for longer periods year-round.

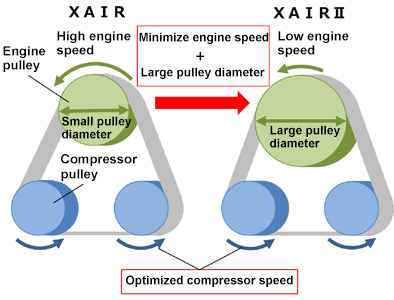

In addition, by enlarging the diameter of the engine pulley, the speed of the compressor was better coordinated with the engine speed, which resulted in improved operation efficiency of both the compressor and the engine.

(2)Enhanced efficiency of the outdoor unit heat exchanger fan

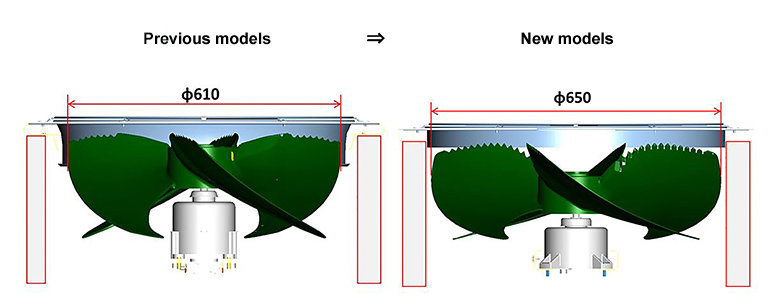

The propeller of the outdoor unit heat exchanger fan was enlarged in diameter from 610 to 650 Φ and given a shrouded- shape configuration to enhance its power saving features.

By successfully combining the features listed above, annual operating efficiency was improved by approximately 24% compared to previous models with the same operating capacity, resulting in a reduction of 20% in primary energy consumption annually.

Notes:

- ※1Heat pump-operated air-conditioning systems in which the compressor of the outdoor unit is powered by a gas engine

- ※2Yanmar standard for commercial buildings

- ※3Load rate under 50% against the rated capacity

- ※4Speed differs by model

- Note: Information contained in News Releases is valid at the time of publication and may differ from the most recently available information.

General Inquiries:

Public Relations Group

General Affairs Div., Yanmar Co., Ltd.

TEL: +81-6-6376-6212

FAX: +81-6-6372-2455

E-mail: koho@yanmar.co.jp

Product Inquiries:

Air-conditioning System Sales Div.

Yanmar Energy System Co., Ltd.

TEL: +81-6-7636-2207

FAX: +81-6-7636-0472

Agriculture

Agriculture

Recreational Marine

Recreational Marine

Recreational Boat

Recreational Boat

Premium Cruiser

Premium Cruiser

Marine Equipment

Marine Equipment

Marine Commercial

Marine Commercial

Propulsion Engines (High Speed)

Propulsion Engines (High Speed)

Propulsion Engines (Medium Speed)

Propulsion Engines (Medium Speed)

Auxiliary Engines

Auxiliary Engines

SCR System

SCR System

Dual Fuel Engine

Dual Fuel Engine

Two-stage Turbocharging System

Two-stage Turbocharging System

Electric Propulsion System

Electric Propulsion System

Energy Systems

Energy Systems

Compact Equipment

Compact Equipment

Industrial Engine

Industrial Engine

Power Generation

Power Generation

Compact Power Products

Compact Power Products