What comes to mind when you think of “rice”? Perhaps steamed rice, sushi, pho noodles, risotto, or donburi? Its use as a staple food, or as a starch in various foods, comes up a lot in people’s minds.

Rice has been a significant part of Japan’s culinary culture and agricultural activities since ancient times. In Japan, it is primarily considered a staple food, with Japanese agricultural technologies and knowledge on how to grow and eat rice known around the world. But in the past few years, a completely new method of using rice is being developed in Japan.

This safe new ingredient consists only of water, and rice

It is an ingredient made of rice, that can be used in place of wheat for foods that normally require wheat product. And it’s called “Rice Gelée”(Patent No. 5840904 approved by the National Agriculture and Food Research Organization). This safe new ingredient consists only of water, and rice produced in Japan.

Yanmar is the first to successfully mass produce Rice Gelée on a global scale.

The company has independently created a technology capable of mass producing Rice Gelée while maintaining high quality standards.

With its high water retention, emulsifying, thickening, and gelling properties, Rice Gelée can be used in a variety of foods. It also solves numerous challenges faced when cooking all kinds of dishes, such as improving the texture of bread and sweets, enhancing the bonding of Hamburg steaks and noodles, and thickening sauces and soups.

Because it is made of only rice and water, it can be used to make gluten-free foods, which have become more popular in recent years, such as breads, sweets, and noodles. For recipes that have conventionally required a mixture of multiple ingredients (such as potatoes, corn, and almonds) to make gluten-free food, this simple rice-based ingredient is all it takes now to achieve an even better texture and flavor.

Y MEDIA has done a story on Rice Technology Kawachi Co.,Ltd., the first company to ever successfully mass produce Rice Gelée, based in the town of Kawachi in Ibaraki Prefecture. We interviewed Yanmar Agri Innovation’s representative director Koji Hashimoto, and Junichi Sugiyama, a technical advisor who was involved in the invention of rice gel (the precursor to Rice Gelée), and learned some interesting details on the potential that Rice Gelée holds for the culinary world.

High-amylose rice is used for this product. Since this type of rice is low viscosity and has a crumbly texture when cooked,it is not ideal for eating as is in Japan. When all ingredients are together, the amount of rice and water simply has to be adjusted to change the gel’s level of elasticity (described later), fitting the recipe being made. It’s such a simple process, and only contains rice and water, yet can potentially revolutionize our eating habits.

No wheat!

Cream puffs made with Rice Gelée, from crust to cream

I never imagined this could be done with gel, but I was able to mix the required ingredients just as when using wheat, bake them in the oven, and make some very nice cream puffs. Not only did they look great, but the crust was flaky, the cream was fluffy and thick, and they tasted delicious. Even the reporters were impressed.

Easily takes shape and does not fall apart

Special characteristics of Rice Gelée that widen the scope of culinary possibilities

After covering how to make Rice Gelée, then how to use it, I’d like to touch on its special characteristics as a food ingredient.

Rice and water are to be used at a 1 to 3 ratio. When pressing it down with a finger, it should have enough elasticity to rise up again. To clearly demonstrate the difference in elasticity, I’d like to show it to you in gel form, but when actually using it as a food ingredient, this would usually be used for noodles. Can Rice Gelée be used to make udon noodles, pasta, etc. to meet the different elasticities required for each type of noodle? This could very well be possible in the future.

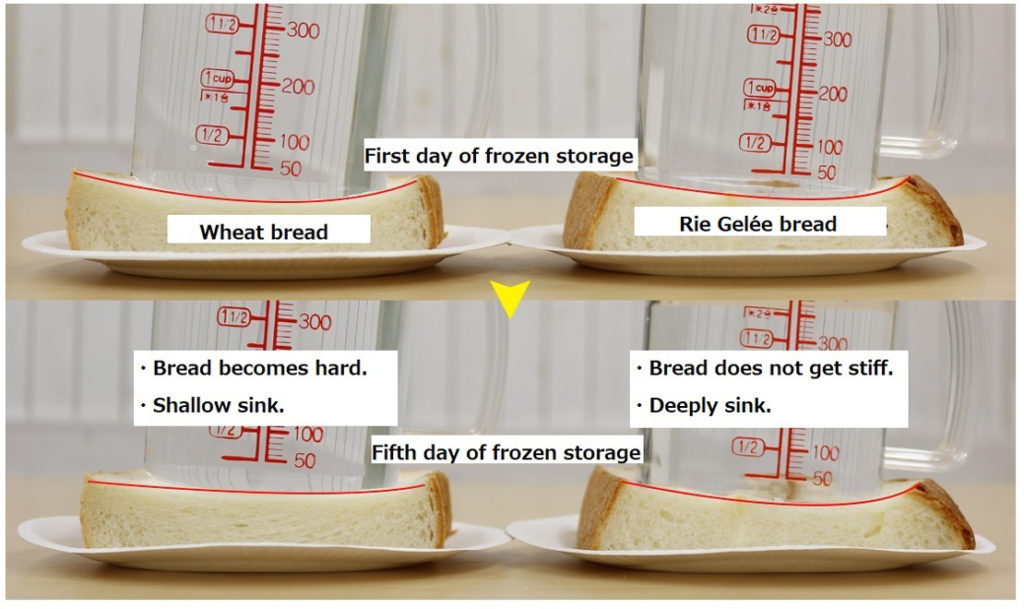

A major feature of Rice Gelée is its high level of water and oil retention. This makes it possible to achieve all sorts of glutinous textures. The images above show a comparison of normal wheat bread with bread that has 20% of the wheat substituted with Rice Gelée. Other than differences in wheat and Rice Gelée ratio, they were baked under identical conditions for comparison. Images shown here are of the bread after it was made and frozen, with the first day on top and the fifth day on the bottom.

Have you ever experienced bread going stale in the house after some days have passed? This is what happened in these examples as well, but as you can see with the bread made with Rice Gelée, it maintains its soft texture even after five days of preservation.

This characteristic can be seen in the video on how to make cream puffs as well. Even after sitting for some time, the cream puffs maintained a crispy crust, fluffy cream without any separation of protein from water content, and the same delicious flavor they had when freshly baked. This characteristic is also being applied to the development of ice cream that takes much longer to melt.

It was created by accident! The story of how Rice Gelée was born

Do you have a pretty good understanding of the Rice Gelée basics now? Next I’d like to get into our interview with two men from Rice Technology Kawachi, where Rice Gelée was successfully mass produced.

Koji Hashimoto

Koji Hashimoto

Representative Director and President of Rice Technology Kawachi / Representative Director of Yanmar Agri Innovation

Junichi Sugiyama

Junichi Sugiyama

Technical Advisor at Rice Technology Kawachi

Rice has been a staple of the Japanese diet since ancient times, and has been essential for Japan to maintain a solid rate of food self-sufficiency. But according to a household survey taken by MIC in 2011, bread had surpassed rice in average annual expenditures per household for the first time ever in Japan, demonstrating the “shift away from rice” phenomenon with actual data. If this “shift away from rice” continues, it will lead to a decrease in the amount of Japanese rice consumed, and rice farmers will have no other choice but to abandon their trade. In attempts to reverse this trend, the Ministry of Agriculture, Forestry and Fisheries supported an increase in the production of rice flour as a new possibility for rice, but rice flour spoils easily, leading to other issues such as the bread and sweets made with such flour quickly drying out and becoming stale.

This is where Mr. Sugiyama’s group came in, performing research and development projects on how to develop a substitute ingredient for rice flour at NARO(National Agriculture and Food Research Organization).

– You said that Rice Gelée was discovered by accident. — But could you tell us more specifically what led to its discovery?

We were exploring the possibility of creating a rice-based bread that was more moist than that made with rice flour, so I tried cooking some rice porridge to start with. I tried high-yield, high-amylose rice as the raw ingredient.

I knew it would swell up quite a bit, but it was interesting to note that rice grains would remain sometimes. So to get rid of the grains in the porridge stage, I tried putting it in a food processor, and it transitioned into gel form. I assumed mixing this gel in with bread dough would be a disaster, so I gave up and left it alone. About three or four days later, a post-doc female researcher found the gel I had left there, and noticed that it had not hardened even though no sugar had been added, as rice dumplings will normally harden to an inedible state without sugar added. She was pretty excited about that.

Then she decided to use that gel to make some sweets and bread, and the practical uses of this gel became more and more apparent. When I saw that, I finally realized how unique the special characteristics of this gel were. So I was able to secure competitive funding from the Ministry of Agriculture, Forestry and Fisheries, and form a research team. And in 2012, we started a 3-year project.

– When you started that project, had you already gotten pretty close to the Rice Gelée as we know it today?

Yes. You could say we had results from the beginning. We were already demonstrating its usefulness in cakes and cream puffs at the presentation phase, so in a way, showing that we had these tangible results helped us secure a budget. We also examined different varieties of rice, and collected old data to write up a paper on it.

Yes. You could say we had results from the beginning. We were already demonstrating its usefulness in cakes and cream puffs at the presentation phase, so in a way, showing that we had these tangible results helped us secure a budget. We also examined different varieties of rice, and collected old data to write up a paper on it.

Aiming for mass production! Considering Rice Gelée for a worldwide gluten free market

Our research team used this 3-year project to develop our “direct gel transformation technique” (Patent No. 5840904) to a commercially viable level. This entails adding water to the rice while in grain form, heating it up, then chopping and mixing it with a high-speed mixer to transition into gel form. We also demonstrated that the gel could be adjusted to various textures, from soft jelly form to a highly elastic rubber ball shape. In October 2013, the following press release came out: “What a surprising texture! A manufacturing method has been developed for a new type of rice-based food ingredient in gel form.” After this, Rice Gelée started showing up on television and in the newspaper.

– When did you start focusing on Rice Gelée?

In November 2015, when I saw Dr. Sugiyama on a TV show. I went to Inashiki City in Ibaraki Prefecture to visit Agricreate’s chairman Kimio Saito, and he told me I came at a good time, because he’d recorded the show on his VCR and wanted me to take a look.

In November 2015, when I saw Dr. Sugiyama on a TV show. I went to Inashiki City in Ibaraki Prefecture to visit Agricreate’s chairman Kimio Saito, and he told me I came at a good time, because he’d recorded the show on his VCR and wanted me to take a look.

A lot of customers who purchase Yanmar farming equipment are rice farmers. And I wanted to come up with something that increases the value of rice, while at the same time gives back to the community. I was always thinking about this, and Rice Gelée came into my mind. I thought this was a rice-based processed ingredient with potential to succeed globally, so I visited Dr. Sugiyama within a month of that experience.

– What was the main reason you wanted to take a chance on this technique?

For four years after applying for a patent, Dr. Sugiyama was approached by a lot of food manufacturers with questions. A lot of them said that, if they could purchase Rice Gelée, they wanted to make gluten free bread, but back then, we could only make about 2 kilos of Rice Gelée at a time with the technology we had. Dr. Sugiyama said he would teach us how to make it, so we should purchase a Blixer (industrial food processor) to do so.

For four years after applying for a patent, Dr. Sugiyama was approached by a lot of food manufacturers with questions. A lot of them said that, if they could purchase Rice Gelée, they wanted to make gluten free bread, but back then, we could only make about 2 kilos of Rice Gelée at a time with the technology we had. Dr. Sugiyama said he would teach us how to make it, so we should purchase a Blixer (industrial food processor) to do so.

If we could implement Yanmar’s technique for stable, full-scale production, we thought we’d be able to turn Rice Gelée into food ingredients and additives.

– So basically, Yanmar took care of the full-scale production and business aspects for Rice Gelée, which had already been completed at the research phase, and then Rice Technology Kawachi was set in motion. Is that correct?

Yes. We created the first ever Rice Gelée production plant, and Yanmar has also applied for a patent on those fundamental techniques. Even in Japan, people suffering from wheat allergies are on the rise. But in North America and Europe where a lot more breads and pastas are consumed, gluten allergies pose serious issues including negative effects on digestive organs and the skin. Because of this, the gluten free foods market continues to expand.

Yes. We created the first ever Rice Gelée production plant, and Yanmar has also applied for a patent on those fundamental techniques. Even in Japan, people suffering from wheat allergies are on the rise. But in North America and Europe where a lot more breads and pastas are consumed, gluten allergies pose serious issues including negative effects on digestive organs and the skin. Because of this, the gluten free foods market continues to expand.

In 2020, we will have a surge in visitors from overseas for the Tokyo Olympics, and demand for gluten free foods is expected to rise. And from a long-term perspective, gluten allergies are clearly on the rise in Japan as the younger generation enjoys a diet with more bread products. So from that angle as well, I think we’ll have to promote gluten free eating habits very soon.

In 2020, we will have a surge in visitors from overseas for the Tokyo Olympics, and demand for gluten free foods is expected to rise. And from a long-term perspective, gluten allergies are clearly on the rise in Japan as the younger generation enjoys a diet with more bread products. So from that angle as well, I think we’ll have to promote gluten free eating habits very soon.

The key to achieving these goals lies with mass production. I feel this is a sense of mission for us.

The key to achieving these goals lies with mass production. I feel this is a sense of mission for us.

Rice Gelée is the key to innovation for creating safe, new food possibilities

The possibilities for Rice Gelée are not limited to gluten-free foods. The physical property of Rice Gelée can be controlled according to how much water is used, ranging from soft jelly to a highly-elastic rubber texture. With its high water retention, emulsion, and low syneresis, the physical property can keep for a long time. By utilizing the special characteristics of Rice Gelée, it can be used in place of additives for maintaining thickness, viscosity, and stability. Basically, it is also expected to play a role in food safety.

– Regarding the benefit of using Rice Gelée for food processing, what uses does it have in addition to gluten-free products?

Its low syneresis is something that no other food ingredient has been able to match. This means it offers new potential for food products to keep for longer periods of time without being hardened and going stale.

Its low syneresis is something that no other food ingredient has been able to match. This means it offers new potential for food products to keep for longer periods of time without being hardened and going stale.

– What are the most significant sales points of Rice Gelée?

I think the number one point is food safety. A lot of young kids have wheat allergies. If even one child has a wheat allergy at a birthday party, that child won’t be able to eat any cake. If a gluten free cake can be used, all kids at the party can enjoy eating it. Rice Gelée is a safe food additive that can make these kinds of scenarios into a reality someday, offering huge potential on a global level. Not only does it offer multiple functions, but since Rice Gelée is only made of rice and water, the food additive list only has to include “rice.”

I think the number one point is food safety. A lot of young kids have wheat allergies. If even one child has a wheat allergy at a birthday party, that child won’t be able to eat any cake. If a gluten free cake can be used, all kids at the party can enjoy eating it. Rice Gelée is a safe food additive that can make these kinds of scenarios into a reality someday, offering huge potential on a global level. Not only does it offer multiple functions, but since Rice Gelée is only made of rice and water, the food additive list only has to include “rice.”

Another point is creating more jobs and expanding consumption in the rice industry. Large-scale processing of Rice Gelée will increase the added value of rice, and if the benefits are recognized overseas, all rice farmers will experience a boost in motivation. I also believe it will lower barriers in the way of new business opportunities.

If producers and factories become a single entity, local rice is used, and processing, distribution, and consumption can be done on a local level, logistics costs can be decreased, and I think this would be the ideal rotation cycle from production to consumption. I’d like to experiment with this in the town of Kawachi to create a model of local production and local consumption.

If producers and factories become a single entity, local rice is used, and processing, distribution, and consumption can be done on a local level, logistics costs can be decreased, and I think this would be the ideal rotation cycle from production to consumption. I’d like to experiment with this in the town of Kawachi to create a model of local production and local consumption.

I hope to see high-amylose rice produced locally, idle facilities utilized efficiently as a production plant for Rice Gelée, local employment generated, and local confectionery shops and bakeries making gluten free bread and additive-free food products. If we can produce a product with an edge on the competition, we can bring in customers locally, throughout Japan, and throughout the world.

I hope to see high-amylose rice produced locally, idle facilities utilized efficiently as a production plant for Rice Gelée, local employment generated, and local confectionery shops and bakeries making gluten free bread and additive-free food products. If we can produce a product with an edge on the competition, we can bring in customers locally, throughout Japan, and throughout the world.

– This also means that rice technologies could be further developed for rice production in the region.

That’s true. And to achieve that, we’re making efforts to lower costs and maintain stable production, while we hope to accumulate enough experience in cultivation methods for growing high quality rice. Once we complete the food value chain model to connect farming with food, we’d like to expand “rice technologies” throughout many regions.

That’s true. And to achieve that, we’re making efforts to lower costs and maintain stable production, while we hope to accumulate enough experience in cultivation methods for growing high quality rice. Once we complete the food value chain model to connect farming with food, we’d like to expand “rice technologies” throughout many regions.

We hear from a lot of local residents who’d like to grow rice locally that can be sold on a global scale. We hope to increase awareness of Rice Gelée, and become a company that can advise others on what benefits can be achieved by using it.

Rice Gelée is created with an ingredient that is closer to us than any other– rice. Through researchers like Dr. Sugiyama and food manufacturers, even more possibilities can be discovered, and it is expected to grow much larger in the years ahead.

But this is not isolated to Japan. We believe Rice Gelée can be used to solve food issues in all sorts of situations around the world. As gluten free and health-conscious demands become more prevalent every year, we are moving in a direction that such foods are not only good for the body, but can also taste better through new ideas and innovations.

Rice Gelée is unrivaled as a food ingredient, not only in Japan but on a global scale, for its benefits in resource circulation, health needs, and flavor enhancement. Keep an eye on Yanmar and Rice Gelée as it continues to expand throughout the world!

Agriculture

Agriculture

Recreational Marine

Recreational Marine

Recreational Boat

Recreational Boat

Premium Cruiser

Premium Cruiser

Marine Equipment

Marine Equipment

Marine Commercial

Marine Commercial

Propulsion Engines (High Speed)

Propulsion Engines (High Speed)

Propulsion Engines (Medium Speed)

Propulsion Engines (Medium Speed)

Auxiliary Engines

Auxiliary Engines

SCR System

SCR System

Dual Fuel Engine

Dual Fuel Engine

Two-stage Turbocharging System

Two-stage Turbocharging System

Electric Propulsion System

Electric Propulsion System

Energy Systems

Energy Systems

Construction

Construction

Industrial Engine

Industrial Engine

Large Generators

Large Generators

Power Products

Power Products