| Type | Zero Tail |

|---|---|

| Operating Weight | 3275 kg |

| Width | 1550 mm |

| Digging Depth | 2820 - 3070 mm |

The ViO33-6 is designed to provide you with true peace of mind, especially in urban environments where space is limited. As a true zero tail swing machine with a low swing radius, it offers exceptional safety benefits, while advanced ergonomics ensure operator comfort as well. It provides outstanding performance, even while greatly reducing fuel consumption and emissions. Other advantages include a ViPPS hydraulic system for balanced smoothness, plus a unique protection system to prolong its working life.

Specifications

| Specifications | ViO33-6 | |

|---|---|---|

| Weight | Transport weight | 3080 kg (canopy) / 3200 kg (cabin) |

| Operating Weight | 3155 kg (canopy) / 3275 kg (cabin) | |

| Engine | Type | 3TNV88-ESBV |

| Fuel | Diesel | |

| Net Power | 18.5 kW / 24.8 HP at 2200 rpm | |

| Gross Power | 18.9 kW / 25.3 HP at 2200 rpm | |

| Displacement | 1.642 l | |

| Max Torque | 85.5 – 94.5 N.m | |

| Starter | 12 V - 1.7 kW | |

| Battery | 12 V – 65 Ah | |

| Alternator | 12 V – 55 A | |

| Hydraulic System | Maximum Pressure | 210 bars |

| Working Pump | 2 double piston pump with variable flow / 1 gear pump / 1 gear pump for pilot line | |

| Max Flow | 2 x 37.4 l/min / 20.9 l/min / 9.9 l/min | |

| Hydraulic Tank | 40 l | |

| Performance | Travel speed | 2.7 / 4.5 km/h |

| Rotation Speed | 10.5 rpm | |

| Digging Force (arm) | 16.1 kN | |

| Digging Force (bucket) | 29.9 kN | |

| Traction Force | n/a | |

| Noise level (2000/14/CE & 2005/88/CE) | Lwag: 94 dBA ; Lpag: 81 dBA | |

| Fuel Tank | 41 l | |

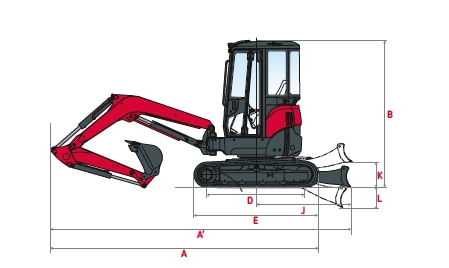

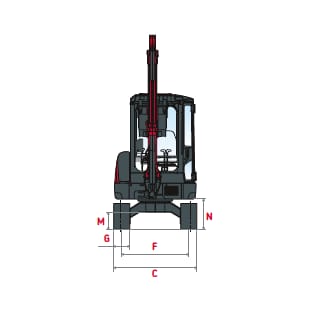

Dimensions

| Dimensions | ViO33-6 | |

|---|---|---|

| A | Overall length | 4470 / 4510 * mm |

| B | Overall height | 2460 mm |

| C | Overall width | 1550 mm |

| D | Length of track on ground | 1710 mm |

| E | Undercarriage length | 2160 mm |

| F | Lane | 1250 mm |

| G | Track width | 300 mm |

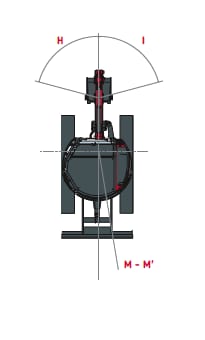

| H | Overall blade width | 1550 mm |

| I | Overall blade height | 330 mm |

| J | Blade distance | 1480 mm |

| K | Max. blade height above the ground | 375 mm |

| L | Max. lowering blade depth | 325 mm |

| M | Minimum ground clearance | 320 mm |

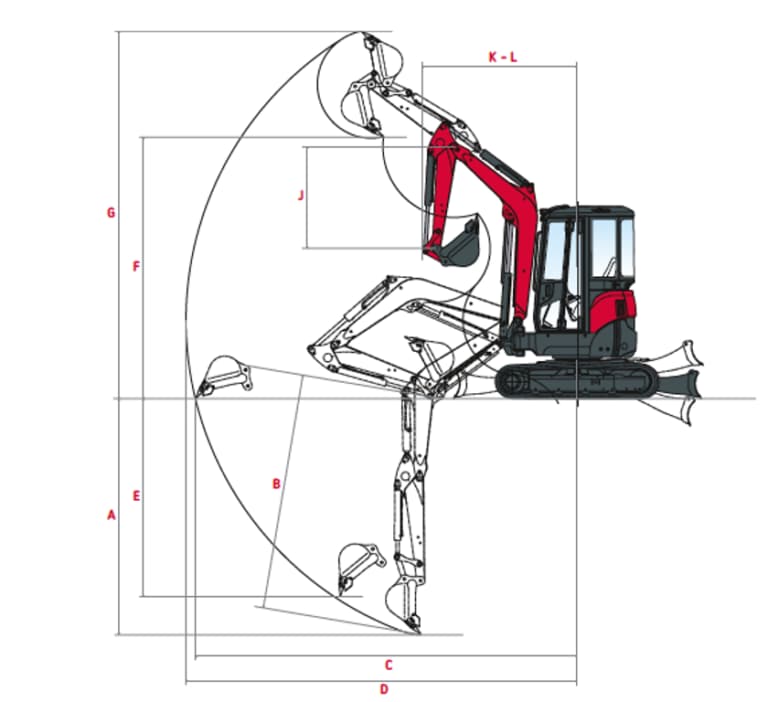

| Dimensions | ViO33-6 | |

|---|---|---|

| N | Max. digging depth - Blade lifted | 2820 / 3070 * mm |

| O | Max. digging depth - Blade lowered | 2950 / 3190 * mm |

| P | Max. digging reach on ground | 4730 / 4980 * mm |

| Q | Max. digging reach | 4870 / 5110 * mm |

| R | Max vertical wall | 2290 / 2550 * mm |

| S | Max. dumping height | 3160 / 3300 * mm |

| T | Max. cutting height | 4550 / 4720 * mm |

| U | Boom swinging base to left | 43° |

| V | Boom swinging base to right | 65° |

| W | Arm length | 1220 / 1470 * mm |

| X | Minimum front swing radius | 2050 / 2120 * mm |

| Y | Minimum front swing radius with boom swing | 1840 / 1900 * mm |

| Z | Rear swing radius | 775 mm |

*with long arm

Features

COMPACTNESS

The ViO33-6 is a true zero tail swing machine, as neither the counterweight nor the front part of the upper frame project beyond the track width. With its front part designed not to protrude, it has a very small turning radius. In addition, it has a swing radius of just 2,615 mm. All this means that safety for both the operator and other on-site workers is enhanced, especially as the rear blind spot has been reduced to a minimum. This makes it ideal for working along walls and in urban environments where space is limited.

ELECTRONICALLY CONTROLLED ENGINE

With an output of 18.9 kW at 2,200 rpm, Yanmar’s 3TNV88-ESBV engine is the result of our continuous efforts to achieve technological advances in fuel consumption and emissions. With the ViO33-6, Yanmar gives further priority to economy and the environment, via features such as an engine control unit that optimises the engine loading. There’s also an auto-deceleration system as standard that sets the engine to idle if the operator doesn’t touch the operating levers for four seconds. In addition, eco-mode effectively controls the engine speed, reducing it by 300 rpm, further lowering fuel consumption.

SMOOTH AND SIMULTANEOUS MOVEMENT

The ViO33-6 uses a ViPPS hydraulic system to obtain the optimal combination in terms of speed, power, smoothness and balance. The system configuration uses a double, variable displacement piston pump, plus two gear pumps. These three main pumps totalise a maximum flow of 95,7 l/min, available for main operating movements, cumulated in the main control valves. The ViPPS system thereby maximises efficiency by allowing smooth and simultaneous performance across all operations, even while travelling.

ADVANCED COMFORT

The large and luxurious cabin has a generously sized entrance door and plenty of legroom. It features as standard a fully adjustable air suspension seat with headrest to reduce body tension and fatigue. Other nice touches include an adjustable wrist rest and translation lever with folding pedals to allow more operator space. Three rear view mirrors aid 360-degree visibility, while new electronic instrumentation, improved ergonomics and optional air conditioning all further contribute towards operator comfort.

EASY OPERATION

The ViO33-6 includes an auxiliary hydraulic circuit which is operated via a proportional control system located on the joystick. This adapts the overall flow and direction of the oil flow. Also making the machine easier to use is a second speed switch located on the blade lever. Control levers are ideally located for exceptional movement precision, while the boom swing benefits from proportional control via the proportional switch located on the right-hand joystick.

STABILITY

The ViO33-6 has been designed to have a very low centre of gravity, thereby ensuring excellent stability in all conditions and good lifting force. The long undercarriage also aids stability and delivers a smoother ride. Optimal mass distribution means that the loading chart of the ViO33-6 can be improved in most positions. The machine’s boom has also been completely redesigned in order to boost its lifting capacity and digging performance, and to provide longer service life.

RELIABILITY

The ViO33-6 benefits from a unique and comprehensive protection system to safeguard its boom and arm cylinders. All cylinder tubes and rods are protected by a spring type steel plate, which reduces drastically the total cost of ownership of the machine. In addition, a unique Kingpost component is attached via a single bolt. This not only makes it last longer, but also reduces vibrations and ensures fewer wear gaps in a critical area of the machine.

Options

EQUIPMENTS

- Steel crawlers

- Rubber pads for steel crawlers YCE – warranty 12 months

- Short arm (1220 mm)

- Proportional 3rd & 4th circuits with potentiometers

- Clamshell bucket circuit (not compatible with 4th hydr. circuit)

- Hydraulic quick hitch line 150 – 165 bar

- Flat face hydraulic quick connectors 3rd circuit

- Additional counterweight (+150 kg)

- Standard biodegradable oil

- 2 front LED working lights

- 1 rear LED work light + 1 LED flashing rotary

- 1 LED flashing rotary

- Beacon light with magnetic base

COMFORT

- Air-conditioning

- Vinyl seat

- Radio

- Documentation box

- Central greasing

SAFETY

- 3 safety valves with welded ring on the bucket link

- Lifting certificate (only for France)

- FOPS 1 protection

- Removable battery cut-off switch

- Keyboard anti-theft device

- Key anti-theft device

- GPS trackunit ME501 standard

- Travel alarm

- Special paint