Yanmar America Equipment Division

ヤンマーテクニカルレビュー

Introduction to Yanmar America (YA)

1.Introduction

For more than one hundred years, Yanmar has been developing the world’s leading engine technologies and products to enrich people’s lives and create a more sustainable future. Founded by Magokichi Yamaoka in Osaka, Japan and now operating in countries across the globe, the company expanded to the North and South American markets in 1950. Today, from our regional headquarters in Georgia, we market, sell, service and support industrial engines for off-road applications and generators, commercial marine engines, sub-compact tractors, compact construction equipment, cogeneration systems, gas heat pump systems and utility task vehicles. All of these products are designed using the latest technologies and with a dedication to reliability, eco-friendliness and premium design; they are then supported in the market by our team of customer service representatives, as well as our strong distributor and dealer network.

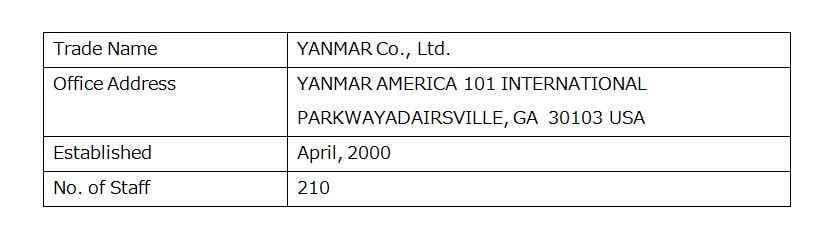

Table 1. Introduction to YA

The YA Facility is shared by many departments ranging from Production to Technical Service. Our newest addition to the facility (Building 2) houses our Agricultural Production Facility and our administrative offices.

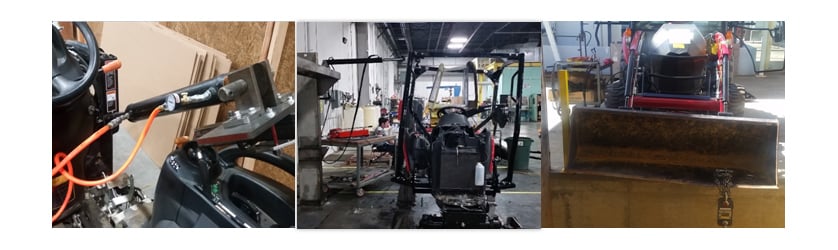

The largest department located in Building 1 is our Parts department. Next to it is our Construction Production area. The back portion of our facility, houses our Tractor Development, Application Engineering, Service and Remanufacturing Departments

2.Industrial Engines

Improving sample engine speed to prospective and current customers is one of the major activities of the YA industrial engine application engineering group. The standard 6 month lead-time from the Yanmar Japan Biwa plant is a difficult proposition for current and prospective Yanmar customers. In order to significantly reduce the lead-time, YA takes a similar production engine, changes parts, and performance tests the new engine configuration. Yanmar America is in the process of completing a new dyno installation for that purpose (shown in Fig-2). The Industrial Engine Team at YA displayed an award winning CAN panel at the 2015 YWK that was developed in house. The panel was designed to improve the end user’s experience with their Yanmar engine. The YJ standard of flashing lights and symbols for regeneration control, was too confusing for the average operator. In 2016 this panel had additional functions added to further help our customers such as remote start (shown in Fig-3). Future development for the YA engine team includes wireless engine diagnostics, the assembly and sale of complete engine packages, and the expansion of Yanmar America’s distributor engine & power pack lineup.

3.Agriculture Equipment

The AG equipment department is focused mainly on providing tractor implements, accessories, and attachments that satisfy our customer’s needs. Two of the major attachments we design and test at YA are the front end loader (shown in Fig-4) and the mid-mount mower (shown in Fig-5). During development of the mid-mount mower we also conduct several industry standard safety tests in addition to strength and performance tests. Other key attachments developed at YA are the front hitch, and the mounting system for backhoe attachments. YA also measures strain data during live operation that is converted using the Rainflow method for later fatigue analysis (shown in Fig-4). The Rainflow data is then used to calculate the estimated fatigue life of a part based Miner’s Rule and the Modified Goodman equation. Both mean stress and amplitude are taken into consideration when estimating fatigue life of a part. YA also has 18+ acres on site for durability testing of loaders, mower, backhoes, and other implements (shown in Fig-6). One of the key function of the test group is checking matching of implements to tractors and stability testing (shown in Fig-7). Static strength loading (stress buggy) and automated cycle testing is also conducted at YA (Shown in Fig-8).

4.YA’s Future Direction

As a whole, YA is striving for world class customer service. The Industrial Engine Division at YA is looking to further the new customer experience with the ability to install Yanmar engines in potential new customer’s applications at Yanmar America. We have already successfully gained a new application by this method and are looking to grow this business model. The Agriculture Equipment Department will focus on bringing new innovative attachments, implements, and solutions to the market. By growing our level of engineering capability at YA we will be closer to the customer and able to react with more agility to our customer’s needs.

著者

Yanmar America Industrial Engine Division

農業

農業

トラクター

トラクター

ジョンディア

ジョンディア

トラクター作業機

トラクター作業機

ガイダンス・自動操舵

ガイダンス・自動操舵

田植機

田植機

コンバイン・乾燥調製

コンバイン・乾燥調製

ミニ耕うん機・管理機

ミニ耕うん機・管理機

乗用管理機

乗用管理機

ティラー・耕うん機

ティラー・耕うん機

草刈機

草刈機

無人ヘリ・ドローン

無人ヘリ・ドローン

野菜機器

野菜機器

大豆機器

大豆機器

畜産・酪農機器

畜産・酪農機器

運搬車

運搬車

除雪機

除雪機

水管理システム

水管理システム

ミニショベル/油圧ショベル

ミニショベル/油圧ショベル

ホイルローダー

ホイルローダー

発電機

発電機

マリンプレジャー

マリンプレジャー

プレジャーボート

プレジャーボート

漁船

漁船

マリンエンジン

マリンエンジン

海洋設備

海洋設備

大形舶用エンジン

大形舶用エンジン

高速主機関

高速主機関

中速主機関

中速主機関

舶用補機

舶用補機 SCRシステム

SCRシステム

二段過給システム

二段過給システム

電気推進システム

電気推進システム

舶用デュアルフューエルエンジン

舶用デュアルフューエルエンジン

金属ばね防振システム

金属ばね防振システム

エネルギー

エネルギー

GHP

GHP

常用コージェネレーション

常用コージェネレーション

非常用発電システム

非常用発電システム

ポンプ駆動システム

ポンプ駆動システム

カーボンニュートラル

カーボンニュートラル 廃熱ソリューション

廃熱ソリューション

建設機械

建設機械

キャリア

キャリア

汎用関連機器

汎用関連機器

投光機

投光機

アタッチメント

アタッチメント

純正部品

純正部品

産業エンジン

産業エンジン

立形水冷ディーゼルエンジン

立形水冷ディーゼルエンジン

立形水冷ガスエンジン

立形水冷ガスエンジン

空冷ディーゼルエンジン

空冷ディーゼルエンジン

横形水冷ディーゼルエンジン

横形水冷ディーゼルエンジン