The Robot Tractor YT488A works in airports for solving the issues of manpower and time constraints in mowing.

VISION02 A Society Where People Can Work and Live with Peace of Mind

Objectives

Transforming harsh labor into comfortable work. Everyone can work safely and earn a steady income while living a rich life in harmony with nature.

Our Products, Services and Support for VISION 02

True Zero Tail Swing Mini Excavator

The rear does not protrude beyond the vehicle width, allowing the excavator to turn in tight circles and work beside a wall without worrying. It offers improved safety and comfort at narrow construction sites.

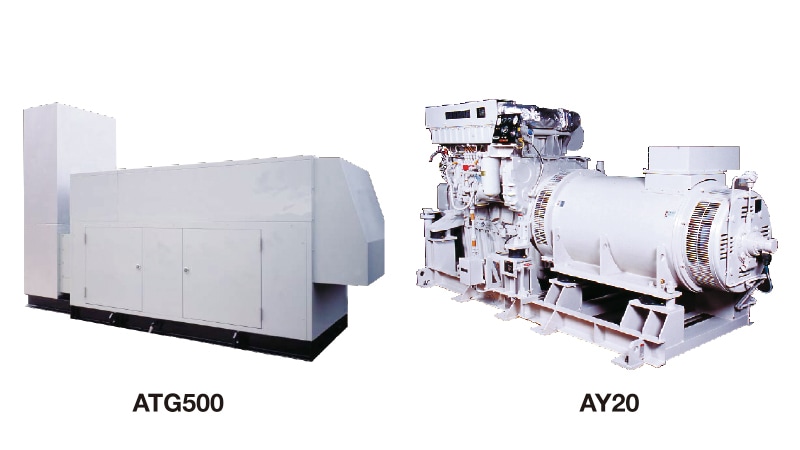

Standby Power Generation Systems

Standby generation systems contribute to ensuring safety of human life, protecting property, helping with relief efforts by taking over the supply of electricity to various equipment in the event of a power outage due to a natural disaster.

Aligned SDGs

Social challenges to be solved related to VISION 02

Contributing Through Business

YANMAR AGRI JAPAN CO., LTD.

Challenges

Airports usually have grass strips called a landing area along the runway to secure the takeoff and landing of aircraft. Of the regular maintenance of this area, mowing, in particular, has been a time-constrained work, not only because of the recent labor shortage, but also because it is restricted to only while aircraft are not in operation. In addition, mowing-related costs, which accounted for 41%* of the maintenance costs for the landing area, have been a major burden for the airport management company.

- * Source: Study Concerning Vegetation Technology for Airport Runways on Construction Surplus Soil, the National Institute for Land and Infrastructure Management

Solution

Yanmar Agri Japan, in collaboration with Kowa Building Maintenance Co., Ltd., verified the effectiveness of using robot tractors for mowing in airport landing areas. Finally, 2 YT tractors, YT488A robots, were delivered to Kagoshima Airport as part of the project promoted by the Ministry of Land, Infrastructure, Transport and Tourism, followed by a total of 8 robot tractors to 4 nationally managed airports: Okadama, Kitakyushu, Yao, and Naha.

Based on location information including GNSS, the user inputs the area and route on the device, and the robot automatically travels along the set route to work. In 2018, Yanmar launched a robot tractor as the first in the SMARTPILOT® series, as a significant step toward achieving labor saving and automation in the agricultural industry, where the decreasing number of farmers and the passing down of expertise are the challenges.

Main Features of the Robot Tractor

- Able to set and start/stop automated operation with simple input on a dedicated device.

- On the route, settings including steering, raising the tractor implements, switching between backward and forward, stopping, turning PTO on/off, and the speed can be adjusted automatically.

- Equipped with a safety sensor that measures the distance to an object with a laser or ultrasonic wave, when an approaching person or an obstacle is detected, it automatically decelerates or stops according to the conditions.

Provided value

The adoption of robot tractors at airports is expected to eliminate the labor shortage issue by automating mowing and grass collection work at runways and other areas, which was previously performed by manned mowers (tractors).

YANMAR ENERGY SYSTEM CO., LTD.

Our cogeneration system capable of serving as a standby generator that can generate enough electricity for the hotel in the event of a power outage for 3 days, helps ensure emergency power supply.

Challenges

Hotel Ambia Shofukaku in Yaizu, Shizuoka, operated by Ambia Corporation, was using an old heavy oil-fired standby generator. They needed a new generator that is energy-efficient and can cover high daytime electricity and heat demand.

Solution

Yanmar Energy System, in collaboration with Tokai Gas and ITO Corporation, proposed a system that combines the BOS*1 micro cogeneration system, CP25D1Z with a standby generator. Led by Tokai Gas, an energy company with close ties to the community, each company leveraged their strengths in their respective fields and successfully introduced the system into Hotel Ambia Shofukaku.

We provided eight units of CP25D1Z for the micro cogeneration system. This system generates electricity with clean energy sources including natural gas and carbon-neutral biogas, which have a low environmental impact. Energy loss is mitigated by effectively using the generated heat for hot water supply and air conditioning.

In the event of a power outage, electricity is supplied by the CP25D1Z within 40 seconds to operate lighting and air conditioning and even if the utility gas supply is stopped, the BOGETS,*2 disaster prevention and mitigation system provided by ITO Corporation will supply combustible gas from LPG standby bulk. The combination of these systems ensures emergency power for three days or more.

This initiative which brings together the technologies of three companies was recognized by the Advanced Cogeneration and Energy Utilization Center for its excellence in terms of leadership, new technology, and energy conservation, and selected for the Cogeneration Grand Award in the Consumer Product Category for 2021.

- *1 Black Out Start for power outages

- *2 BOGETS is a registered trademark of ITO Corporation

Provided value

Being conscious of electricity and heat usage contributes to energy efficiency and reduction of CO2 emissions. In addition, as a distributed generation system, it will be possible to supply electricity and gas even in emergencies such as power outages due to disaster, ensuring an emergency power supply for three days. This will contribute to the safety and security of hotel customers and employees.