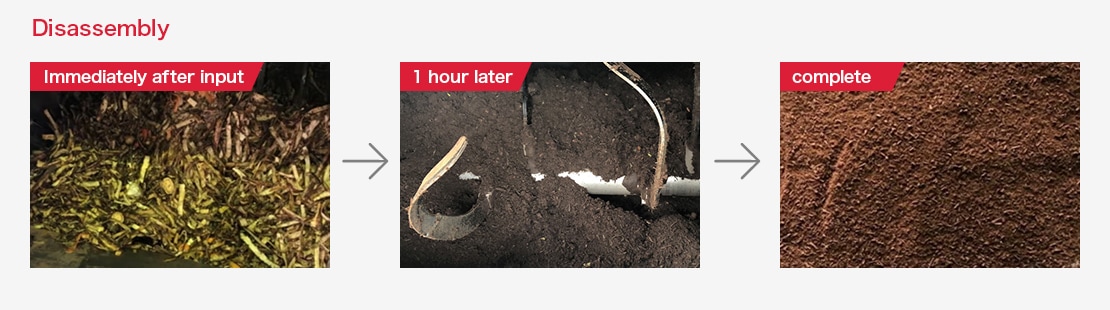

The YC100 Bio-composter development project started in 2019. The development team surveyed the current state of the composter market and were able to identify the problem of material forming balls in the compost and not decomposing. Research focused on this problem with the team succeeding in developing two new technologies.

The first of these was the Air Direct Injection (ADI). Most conventional mechanical composters employ a system that draws air into the reaction chamber. In the YC100, ambient air is heated and forced into the tank under pressure. Compared to natural aspiration models, in the YC100, the air has greater contact with the agitated material, improving drying efficiency. This required specialized solutions to ensure that the reaction chamber was airtight and free from leaks. Developers were able to reduce the size of the machine to a width of 2,500 mm, a depth of 1,400 mm, and a height of 1,940 mm for more compact installation.

The second technology was Yanmar’s original automatic control and stirring technology. Yanmar’s proprietary stirring claws are based on the shape and arrangement of the claws used in tractor implements. By applying rotary tiller technology to the Bio-composter’s rotary stirrer, developers were able to achieve an even stirring to maintain a stable environment inside the tank. Yanmar also developed a system to optimally control the inside of the tank by automatically weighing material added to the tank and analyzing and controlling factors such as temperature, air volume, stirring speed, and the elapsed time of processing. The program can instruct users to increase the power to encourage drying if the material is heavy, or reduce the power if the material is light. Not only is it easy to use, but it also reduces power consumption.

In addition to these new technologies, hygiene is improved by equipping an activated carbon adsorption type deodorizer that suppresses the odor of food waste during processing. Operation is simple and automatic and users can start the processing cycle with the push of a button.

Agriculture

Agriculture

Tractor

Tractor

Implements

Implements

Combine Harvesters

Combine Harvesters

Rice Transplanter

Rice Transplanter

Sugarcane Harvesters

Sugarcane Harvesters

Recreational Marine

Recreational Marine

Marine Commercial

Marine Commercial

Compact Power Products

Compact Power Products

Compact Equipment

Compact Equipment

Excavators

Excavators

Attachments

Attachments

Industrial Engine

Industrial Engine

Energy Systems

Energy Systems

Power Generation

Power Generation