Marine Solution Group,

Solution Development Department,

Development Division,

Yanmar Marine International Asia Co., Ltd.

YANMAR Technical Review

Solutions for Reliable Oyster Farming Production

Use of Biotech Practices

Abstract

Japan’s oyster farming industry has been suffering from poor harvests of wild seed and high levels of mortality due to the recent rises in seawater temperature. This has created a need for the reliable artificial production of seed to facilitate forward planning as well as the development of varieties with superior traits, including the ability to avoid weight loss at higher water temperatures and the mortality associated with spawning. To meet these needs, Yanmar has developed technology for the high-density production of artificial oyster seed and infertile triploid oysters with superior growth characteristics.

The high-density larvae cultivation system requires less labor to manage and can produce oyster seed using smaller production equipment. Meanwhile, expertise built up over time has enabled the successful production of triploid oysters. Because they do not undergo spawning and the associated stresses, triploid oysters have greater tolerance for rises in seawater temperature and other changes in their environment. Using these core technologies, Yanmar supplies its triploid oyster seed either attached to scallop shells or as single-seed oysters.

1. Introduction

Oysters are one of the most important aquaculture species and are cultivated around the world. As they can be grown without feeding and with little impact on the surrounding marine environment and ecosystem, they are also recognized as a low-cost and sustainable fishery.

Japan is the world’s third largest producer with a long tradition of oyster aquaculture that in some places dates back more than 200 years. New cultivation practices have been investigated over recent years in different locations. With this has come a steady stream of regionally branded oysters entering the market and earning popularity as distinctive regional delicacies from different parts of Japan, whether in raw or processed form. Yanmar, meanwhile, has pursued an ongoing program of research and development aimed at supporting oyster aquaculture. This article presents examples of this work in the form of Yanmar solutions for the reliable supply of high-quality oysters to consumers.

2. Current State of Oyster Farming

2-1. Oyster Cultivation Process

The cultivation of oysters in Japan generally begins with the collection of wild seed. Also known as spat, these are the larvae hatched from the eggs of wild oysters living along the coastline. The collection of these seeds takes place in early to late summer when oysters spawn.

Once collected, the seed is cultivated in accordance with its growth stages, initially in growing racks located in tidal flats and shifting later to offshore rafts. The oysters take one to three years to reach edible size. Inside their shells, oysters put on weight during the cooler months from fall to winter and are in season from October and harvested from then until the following May.

2-2. Problems Arising over Recent Years

Oyster farm production has become erratic over recent years. Poor harvests of wild seed have become more common, resulting in shortages of oyster seed for aquaculture. This has been due to high levels of farmed oyster mortality*1 in regions that have delivered reliable production volumes in the past. While simple explanations for what is causing this have proven elusive, higher sea temperatures and other changes in the marine environment are believed to be major factors.

The average water temperature in the seas around Japan has risen by 1.16°C over the past 100 years*2. The habitats of marine flora and fauna have also shifted toward regions that previously had cooler water temperatures, with particularly marked migration reported in phytoplankton, which underpin the ecosystem*3. As phytoplankton are the primary food source for oysters, these changes in the environment are also believed to be having a major impact on oyster farming.

For now, these instances of poor seed harvests and high oyster mortality remain localized and of short duration. However, given the anticipated changes in the marine environment, action will need to be taken if oyster farming is to continue to deliver reliable harvests in the future. Two challenges to achieving this are ensuring a reliable supply of seed and minimizing oyster mortality.

- *1The death of an organism being cultivated.

- *2https://www.data.jma.go.jp/gmd/kaiyou/data/shindan/a_1/japan_warm/japan_warm.html

- *3Impact of climate change on coastal environments and ecosystems: Marine Ecology Research Institute 2018 Symposium on Climate Change and its Effect on Marine Organisms

3. Yanmar’s Oyster Cultivation Solution

3-1. Research into Seed Production at Yanmar’s Marine Farm

Since 1988, Yanmar has been working on aquaculture research and development at its Bio Innovation Center Marine Farm Facility at Kunisaki in Oita Prefecture. And, since 2008, this has also included the development of solutions for the two challenges facing oyster cultivation, namely ensuring a reliable supply of seed and minimizing oyster mortality. The following sections describe some of the results of this work.

3-2. Reliable High-Volume Production of Seed for Aquaculture

3-2-1. Cultivated Seed and Standard Production Practices

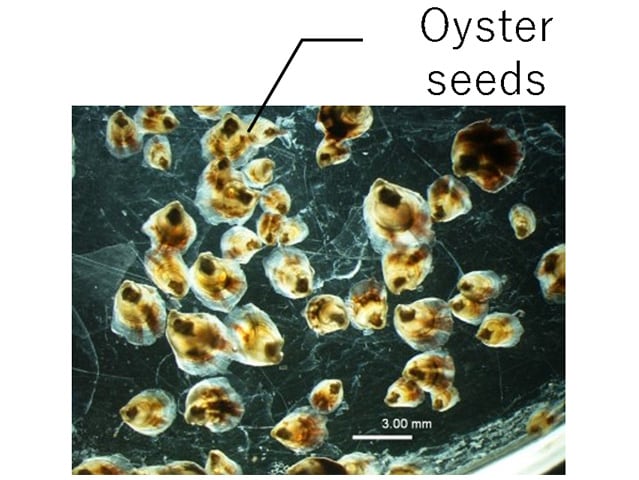

Rather than relying on wild seed alone, augmenting supplies with cultivated seed artificially grown from harvested eggs is necessary to ensure a reliable supply of oyster seed for aquaculture. In fact, the production of artificial seeds, primarily by private-sector companies, is already common in America, the world’s fourth largest producer of cultivated oysters. This has come about as changes in the marine environment have made the harvesting of wild seed problematic in Washington State, a major region for oyster production. It may be that the future will bring complete reliance on cultivated seed. Cultivated seed is produced in land-based tanks. Fertilization is done using eggs and sperm harvested from mature oysters. The larvae that hatch from the fertilized eggs are transferred to tanks where they grow into oyster seeds over a period of two to three weeks. These seeds are then used in marine oyster farms (see Table 1).

Table 1 Oyster Lifecycle

| Growth stages | Seed production | Cultivation | |||

|---|---|---|---|---|---|

| Fertilized egg | Larvae (early stage) |

Larvae (late stage) |

Juvenile | Adult | |

| Photograph (Magnification is different in each case) |

|

|

|

|

|

| Size | 20 to 40 μm | 50 to 70 μm | 300 to 350 μm | 0.5 to 20 mm | 5 to 20 cm |

| Cultivation site | Water tank | At sea | |||

3-2-2. Problems in Production of Cultivated Seed

The production of cultivated seed has been studied around the world for more than 50 years, with the result that production practices are now well established. Unfortunately, two problems arise when seeking to achieve reliable, high-volume seed production.

Problem 1: Need for large facilities

Past practices were only able to cultivate a small quantity of larvae per unit volume using seawater. That is, the low density of cultivated larvae meant that large volumes of seawater were needed to produce seed in high volume. This in turn required very large tanks. As the seawater treatment systems and other auxiliary equipment used with the tanks were also large in size, the space needed for all this equipment was one of the factors restricting where such facilities could be built.

Problem 2: High workload for managing operation

As oyster larvae are delicate, reliable seed production requires precise control of cultivation to prevent the larvae from dying. The quality of the seawater supplied to the tanks needs to be maintained, including adequate removal of contaminants and pathogens. Frequent tank cleaning and replacement of the seawater are also needed. Larvae cultivation is very labor-intensive. For example, the growing larvae need to be carefully collected before tank cleaning can take place. Naturally, larger facility sizes make these labor requirements even larger.

3-2-3. Use of High-Density Larvae Cultivation System to Reduce Facility Size

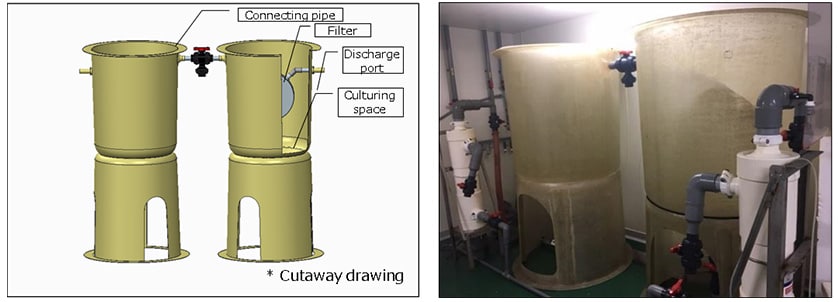

To address these problems and enable the reliable production of cultivated seed in high volumes, Yanmar has developed a high-density larvae cultivation system (see Fig. 2).

Table 2 compares the Yanmar system to conventional practice. A feature of Yanmar’s system is that larvae can be grown at around 10 times the usual density using water tanks that are only one-10th the size. Cultivation also only requires about one-third as much seawater. This means that the equipment used for growing can be kept small even when producing large quantities of seed.

3-2-4. Reduced Cultivation Workload when Using High-Density Larvae Cultivation System

The system is also equipped with functions for making larvae cultivation simpler, resulting in a 60% reduction in the amount of labor required to manage cultivation compared to past practice (see Table 2).

The system uses two water tanks. As the tanks require daily cleaning when the density of larvae under cultivation is high, the larvae are alternated between the two tanks. The tanks are linked by a connecting pipe through which the larvae are relocated to the opposing tank to allow for cleaning. As use of a net or other filter in this transfer process would risk injury to the larvae, the system is designed so that they can be relocated by means of water flow alone, with this flow being controlled by means of valves. This makes it easy to relocate the larvae without injuring them. Also, because the material excreted by the larvae sinks to the tapered bottom of the tank, the flow rate for transferring between tanks is chosen so as to ensure that this material is left behind and only the larvae are relocated.

The system also keeps the tanks constantly supplied with seawater from which pathogens and other contaminants have been removed by precise filtering. Overflowing seawater passes through a filter at the top of the tank and is discharged from a port. The seawater in the tanks is constantly replenished and they are kept filled with clean and suitably oxygenated water. This prevents the accumulation of old seawater and keeps the water quality at a level suitable for larvae growth.

Table 2 Performance Comparison of Larvae Cultivation Systems

| Unit | Yanmar | Conventional* | |

|---|---|---|---|

| Water tank size | kL | 1 | 10 |

| Cultivation density (initial) | Larvae/ml | 100 | 10 |

| Seawater requirement** | kL/day | 25.9 | 75.0 |

| Labor requirement*** | Man-days | 0.5 | 1.25 |

* Based on research by Yanmar (standard technique used overseas)

** Daily seawater requirement for a 1 kL system

*** Daily labor required to manage cultivation in a 1 kL system

3-3. Development of Superior Oyster Varieties

3-3-1. Breeding of Triploid Oysters with Greater Environmental Resilience

Use of selective breeding to develop superior varieties that can withstand harsh environments is one effective way to address the problem of high levels of mortality. This has directed the attention of the global oyster farming industry toward the adoption of triploid oysters*4.

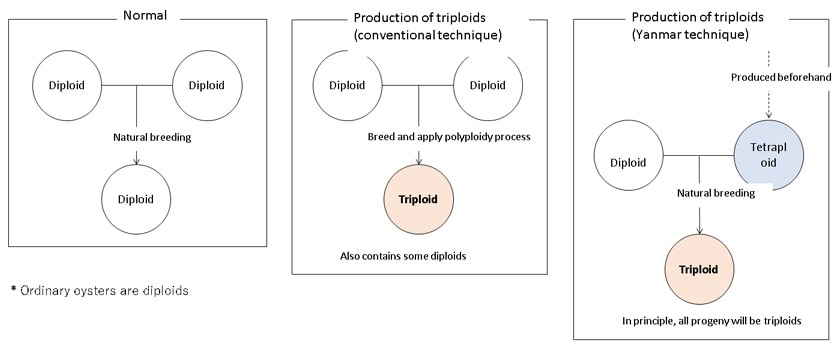

Most organisms are diploid, meaning that each cell has two sets of chromosomes. Triploids are created by artificially inducing an additional set of chromosomes. Triploid organisms do not tend to produce eggs internally. As a result, these organisms generally grow faster and reach larger sizes because the nutrition they receive is not consumed in the process of egg production. For this reason, triploids are already found among some farmed fish such as salmon and ayu (sweetfish).

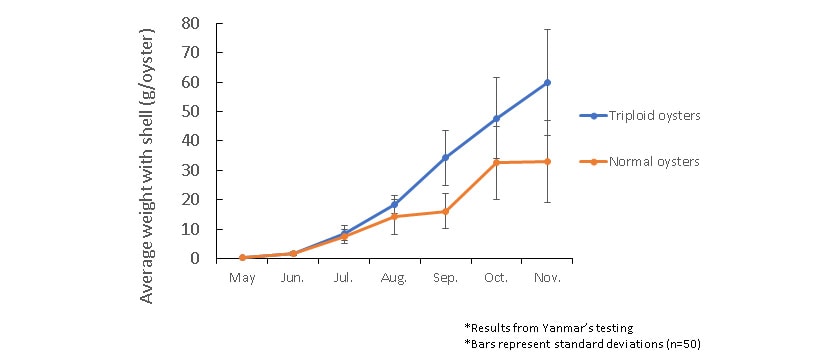

Triploid oysters likewise tend not to produce eggs or sperm. As they avoid the stresses of reproduction and do not weaken during spawning, they are resistant to the post-spawning mortality frequently seen among normal oysters*4. As triploid oysters also grow more quickly (see Fig. 3) and avoid the weight loss that occurs during spawning, they offer commercial benefits to farmers who are able to achieve oyster harvests up to 50% higher*5.

3-3-2.-Issues with Producing Triploids from Normal Oysters

The production of triploid oysters is already a widespread practice around the world. While they have been produced in Japan for more than 20 years, in most cases this is done by a special process performed on the fertilized eggs of normal diploids. The problems with this are that the resulting triploid seed often also contains diploid seed, and the process is not well suited to high-volume production.

3-3-3. Yanmar’s Method for Triploid Oyster Production

In response, Yanmar has adopted a way of producing triploid seed that works by first artificially producing tetraploid oysters with four sets of chromosomes and then crossing these with diploids using the natural breeding process (see Fig. 4). In theory, this method should produce 100% triploids. It also facilitates high-volume seed production as, from there, it is simply a matter of hatching the fertilized eggs obtained by natural breeding and growing the resulting larvae.

While the theory behind this method is well established, in practice it is influenced by many variables such as the conditions at the time of production and differences in the number of breeding stock. As a result, practical expertise needs to be acquired through an ongoing process of trial and error. While the development process was an arduous one, requiring the persistence to deal not only with the technical difficulties, but also to manage a cultivation process that lasts three or more years in order to cope with a reproduction cycle that spans three or more generations of oysters, Yanmar was ultimately successful. With expertise still being acquired on a daily basis, work on further improvements continues with the goal of supplying even better varieties.

- *4S. Akashige, T. Fushimi, Fisheries Science, 58(6), 1063-1071 (1992) Growth, Survival, and Glycogen Content of Triploid Pacific Oyster Crassostrea gigas in the Waters of Hiroshima, Japan

- *5Based on the results of cultivation trials by Yanmar. As cultivation results vary depending on the production conditions, no guarantees can be provided regarding seed productivity and harvest size.

4. Commercially Available Triploid Oyster Seed

Yanmar has utilized the production technologies described in this article for the commercial production of oyster farming seed intended to suit two different farming methods.

4-1. Oyster Seed on Cultivators

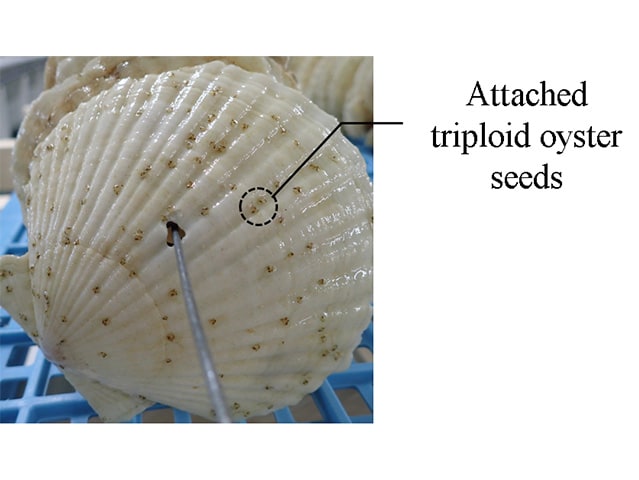

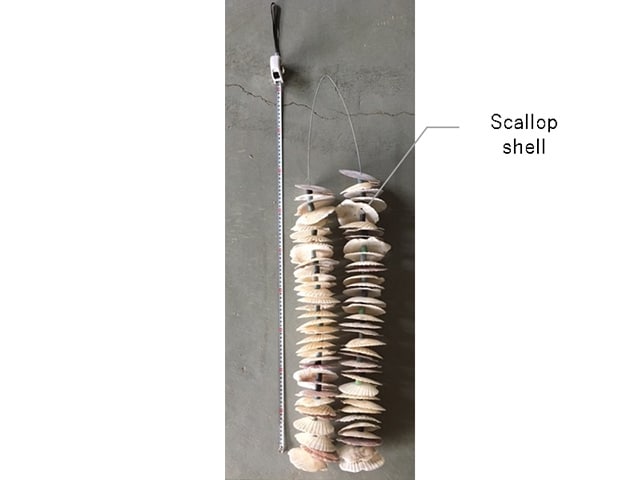

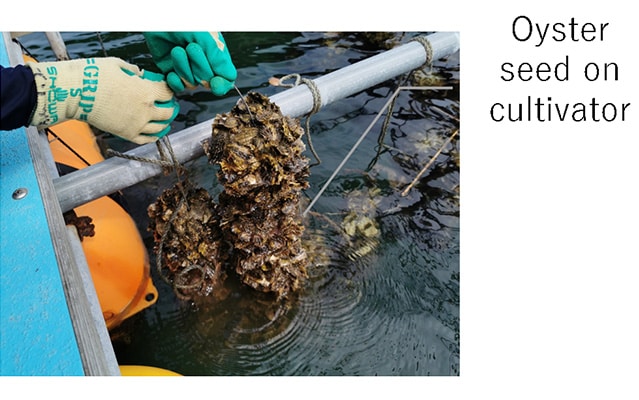

The first method uses oyster seed on cultivators (see Fig. 5). These are created by having oyster seed attach itself to strings of scallop shells that are used as a growing substrate (see Fig. 6). While juvenile oysters remain free-swimming up until late in the larval stage (see Table 1), they then attach themselves to a suitable location such as a rock to live out the rest of their life cycle. These cultivators take advantage of this ability of oyster larvae to secure themselves to a surface. By suspending the strings of scallop shells in seawater that is rich in nutrients, the attached oyster seeds will grow in place (see Fig. 7) until they are harvested as adult oysters. As this form of cultivation is compatible with the traditional method using seed collected from the wild as described earlier (in 2.1 Oyster Cultivation Process), it is used for more than 90% of oyster farming in Japan. The oysters produced by this method are also suitable for consumption in a wide range of forms, whether it be as shelled oysters, fried oysters, or in processed foods.

4-2. Single-Seed Oysters

he second method is to supply the oysters as single seeds (see Fig. 8). As the seeds are separate from one another, this form suits cultivation practices in which the oysters are grown individually. It works by placing a fixed number of seeds in a mesh bag (see Fig. 9) or other enclosure that is then suspended in the sea for the oysters to grow. While this form of cultivation takes more effort, it is good for producing high-quality well-formed oysters (see Fig. 10) and is used for markets such as oyster bars where the shellfish are intended to be eaten raw*6.

- *6The supply of oysters to be consumed raw requires certain levels of seafood hygiene standards and handling practices. Yanmar does not guarantee the freshness of oysters post-cultivation.

4-2-1.

5. Conclusions

This article has described two Yanmar solutions for ensuring reliability in the volume of oyster production: a high-density larvae cultivation system for the reliable production of oyster seed in high volumes and a technique for producing triploid oysters that enables the supply of superior varieties.

Yanmar’s Marine Farm engages in the research and development of solutions for the next-generation aquaculture industry as it makes the transition from seafood gathering to seafood cultivation. By protecting precious fisheries for the future, Yanmar intends to continue its work of helping everyone to enjoy a plentiful and varied diet.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Innovation & Technology Division, Technology Strategy Division.

Author

Agriculture

Agriculture

Recreational Marine

Recreational Marine

Recreational Boat

Recreational Boat

Premium Cruiser

Premium Cruiser

Marine Equipment

Marine Equipment

Marine Commercial

Marine Commercial

Propulsion Engines (High Speed)

Propulsion Engines (High Speed)

Propulsion Engines (Medium Speed)

Propulsion Engines (Medium Speed)

Auxiliary Engines

Auxiliary Engines

SCR System

SCR System

Dual Fuel Engine

Dual Fuel Engine

Two-stage Turbocharging System

Two-stage Turbocharging System

Electric Propulsion System

Electric Propulsion System

Energy Systems

Energy Systems

Compact Equipment

Compact Equipment

Industrial Engine

Industrial Engine

Power Generation

Power Generation

Compact Power Products

Compact Power Products