A new challenge to reduce user's burden and create a society where people can work with a peace of mind

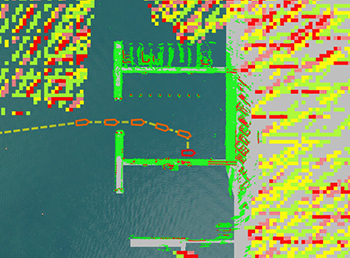

Marine business is one of Yanmar's strengths. We continue to support offshore workers with a variety of our products and services born from a new perspective. Yanmar focuses on “docking”* which requires skill in ship navigation but is a huge stress for users. Yanmar has undertaken the development of an "Auto-docking System" for smooth and safe docking without any troublesome operation, and an "Auto-navigation Robotic Boat" that automatically determines safe route to control sailing at sea. The development of these systems will be a great advantage not only for the marine business, but also for the fisheries market where the population of workers is decreasing and the demand for aquaculture is expanding, benefitting the dangers involved in offshore operations. Since 2017, Yanmar has been developing these systems while considering to alleviate the burden of offshore laborers by replacing and reducing offshore work.

Initially, we began to develop this technology for the commonly used single-propeller and single-rubber boat, similar to those seen in automobiles. As the project proceeded, it was clear that an enormous amount of man-hours was necessary for development due to the difficulty in controlling docking for a single-propeller and single-rudder ship. The reason, being not only its vulnerability in keeping a stable position from winds and waves, but also its lack of flexibility for directly applying force in a lateral movement. With the desire to release a new product as quickly as possible, we switched to applying a twin-propeller and twin-rudder ship equipped with multiple propulsion units and decided to consolidate man-hours for development. By installing a propulsion distribution equipment that can move the ship in any direction and applying the dynamic positioning system that we developed in 2015, Yanmar finally completed the basic technology for the Auto-docking and Auto-navigation system.* To approach the boat to the pier, raft, or shore on the ocean.