With the expected future increase in global demand for building renovation works, Yanmar Construction Equipment has set its focus on works such as interior demolition, works which up until now have been limited to being done by hand. In anticipation of mechanization and intelligent automation in new markets, we at Yanmar propose a range of concept construction equipment with a view towards the future in 2035. Today at Y MEDIA we interviewed two of the people involved in the development of this concept construction equipment: Kazuki Takeda (Engineering & Development Dept., Design Dept., Design Group 2; joined Yanmar in 2014) and Fumitaka Hasegawa (Engineering & Development Dept., Design Dept., Electric & Hydraulic Group.

; joined Yanmar in 2008.) The interviewer for this article is one of our new employees, Kotaro Nomura (Engineering & Development Dept.

; joined Yanmar in 2018.)

![]() Develops the construction equipment designed to support the future construction industry. Can you tell us what were the driving factors behind this project?

Develops the construction equipment designed to support the future construction industry. Can you tell us what were the driving factors behind this project?

![]() One of the core ideas at Yanmar Construction Equipment is to develop products based on not just the present demand, but by taking into account the possible needs that may arise in the next couple of decades, in order to keep pace with the times. We call this concept “demand creation type product development”. In September 2016, we launched the project “Creation of Concept Construction Equipment Models” with the aim of making futuristic equipment based on the proposals that are beyond the current customer demands in terms of future-proofing their business. A survey was conducted for the project and project members were chosen based on its results. Out of all the members, five are from the Development Department and one is a Design Assistant from the Design Strategy Group. The team gets together twice each month for project promotion.

One of the core ideas at Yanmar Construction Equipment is to develop products based on not just the present demand, but by taking into account the possible needs that may arise in the next couple of decades, in order to keep pace with the times. We call this concept “demand creation type product development”. In September 2016, we launched the project “Creation of Concept Construction Equipment Models” with the aim of making futuristic equipment based on the proposals that are beyond the current customer demands in terms of future-proofing their business. A survey was conducted for the project and project members were chosen based on its results. Out of all the members, five are from the Development Department and one is a Design Assistant from the Design Strategy Group. The team gets together twice each month for project promotion.

![]() What were the stumbling blocks during the development?

What were the stumbling blocks during the development?

We need to know that something that is impractical today may become practical tomorrow,

![]() Normally, if full model changes are made, it is assumed that the full-scale production will begin two to three years later. Even though our focus is generally on thinking about functions which can solve current customer issues, the whole idea behind creating concept construction equipment is to think 20 years into the future. We need to know that something that is impractical today may become practical tomorrow, and avoid having mental blocks regarding practicality as they may hamper the futuristic property of the equipment. But that doesn’t mean we can take excessive liberty. We must not end up with a design having “doors everywhere”, something which belongs more in a cartoon than in the real world. So ultimately, the difficulty lies in finding that right balance between realism and pure imagination

Normally, if full model changes are made, it is assumed that the full-scale production will begin two to three years later. Even though our focus is generally on thinking about functions which can solve current customer issues, the whole idea behind creating concept construction equipment is to think 20 years into the future. We need to know that something that is impractical today may become practical tomorrow, and avoid having mental blocks regarding practicality as they may hamper the futuristic property of the equipment. But that doesn’t mean we can take excessive liberty. We must not end up with a design having “doors everywhere”, something which belongs more in a cartoon than in the real world. So ultimately, the difficulty lies in finding that right balance between realism and pure imagination

![]() To begin with, I probably did not have as much knowledge concerning construction equipment as any of the other members because I am usually involved in designing of the electrical equipment such as harnesses, LCD monitors and electrical controllers used in construction equipment. This was the first time I was involved in the creation of the construction equipment as a whole, as compared to my usual job where my focus is only on specific parts of the equipment. Thanks to this project, I got an opportunity to learn from the persons in charge of other duties while using the experience I have gathered so far from my usual work. It gave me a detailed insight on the construction equipment in its entirety.

To begin with, I probably did not have as much knowledge concerning construction equipment as any of the other members because I am usually involved in designing of the electrical equipment such as harnesses, LCD monitors and electrical controllers used in construction equipment. This was the first time I was involved in the creation of the construction equipment as a whole, as compared to my usual job where my focus is only on specific parts of the equipment. Thanks to this project, I got an opportunity to learn from the persons in charge of other duties while using the experience I have gathered so far from my usual work. It gave me a detailed insight on the construction equipment in its entirety.

![]() As this project is going to be critical in deciding the future of the company, it kept all of us on our toes.

As this project is going to be critical in deciding the future of the company, it kept all of us on our toes.

![]() Could you tell us about some of the defining characteristics of concept construction equipment?

Could you tell us about some of the defining characteristics of concept construction equipment?

![]() Yanmar Construction Equipment has been a pioneer in the manufacturing of compact construction equipment. But how can we best utilize our long-held “manufacturing DNA” to deliver value to our customers? We thought about this and came up with the idea of providing value in new forms which can help create a foundation of prosperous lifestyle for people. We have decided to provide this new value in the form of electrification and intelligent automation of the interior demolition work, which is presently a handwork. Our compact construction equipment will be made futuristic to cope up with the demands that may arise after 20 years. This will be done with both battery-powered and electric motor-powered equipment. We also happen to think that the future urban planning will not be characterized by mass production and mass consumption, but will be more about using the existing things more effectively and re-purposing them for new applications. We have named this movement “renovation construction equipment” for A Sustainable Future.

Yanmar Construction Equipment has been a pioneer in the manufacturing of compact construction equipment. But how can we best utilize our long-held “manufacturing DNA” to deliver value to our customers? We thought about this and came up with the idea of providing value in new forms which can help create a foundation of prosperous lifestyle for people. We have decided to provide this new value in the form of electrification and intelligent automation of the interior demolition work, which is presently a handwork. Our compact construction equipment will be made futuristic to cope up with the demands that may arise after 20 years. This will be done with both battery-powered and electric motor-powered equipment. We also happen to think that the future urban planning will not be characterized by mass production and mass consumption, but will be more about using the existing things more effectively and re-purposing them for new applications. We have named this movement “renovation construction equipment” for A Sustainable Future.

![]() A lot of the existing buildings in Japan were built during the bubble economy period in the 1980s, but the conventional wisdom is that the life expectancy of these buildings is only about 50 years.

A lot of the existing buildings in Japan were built during the bubble economy period in the 1980s, but the conventional wisdom is that the life expectancy of these buildings is only about 50 years.

That means exactly 20 years from now, the number of buildings reaching the end of their lifespan will increase, and with that will increase the demand for renovation of buildings. In contrast to this, the labor workforce for performing such work will decrease over the same time span. For this very reason, we think that mechanization of workforces will increase in the years to come. So one of the defining characteristics of this project is the initiative towards limiting the workload and improvement of work efficiency. Another major issue we face is the disposal of waste material created during interior demolition work. In addition, we have taken measures to simplify this work.

![]() If we can deliver on these points, we believe that the pace of work can be increased while reducing the required man hours. For example, the work that currently requires three people to work for three days can be completed by two workers in two days. I am sure every client wants work to be completed as quickly as possible. Thus, the mechanization and intelligent automation can reduce the labor cost, and ultimately the overall cost.

If we can deliver on these points, we believe that the pace of work can be increased while reducing the required man hours. For example, the work that currently requires three people to work for three days can be completed by two workers in two days. I am sure every client wants work to be completed as quickly as possible. Thus, the mechanization and intelligent automation can reduce the labor cost, and ultimately the overall cost.

![]() Can you tell us about what we can do with renovation construction equipment?

Can you tell us about what we can do with renovation construction equipment?

![]() In old buildings, the wiring and piping get destroyed or damaged because it is sometimes not possible to know where exactly they are located. On top of this, you also have another immensely time-consuming job in the form of sorting the waste after demolition.

In old buildings, the wiring and piping get destroyed or damaged because it is sometimes not possible to know where exactly they are located. On top of this, you also have another immensely time-consuming job in the form of sorting the waste after demolition.

Considering these problems, we have worked mainly on the following four points:

![]() The method of construction of structures differs between the western countries and Asia, and so does the type of onsite work for renovation projects. However, by making the following three concepts a common feature no matter where they are employed, we hope to be able to create the construction equipment which can be used on any worksite anywhere in the world:

The method of construction of structures differs between the western countries and Asia, and so does the type of onsite work for renovation projects. However, by making the following three concepts a common feature no matter where they are employed, we hope to be able to create the construction equipment which can be used on any worksite anywhere in the world:

1. The equipment size that can be mounted onto an elevator

2. Superior versatility with interchangeable attachments, 3. Automation.

![]() A variety of opinions must have been put forth at the project meetings. Was it difficult to zero in on some to come up with something concrete?

A variety of opinions must have been put forth at the project meetings. Was it difficult to zero in on some to come up with something concrete?

![]() Interestingly, we had one proposal which imagined work taking place in space. The conversation soon started to balloon out beyond something that should be confined to the next five to ten years. However, the proposal was ruled out as work in space is not realistic from the demand perspective.

Interestingly, we had one proposal which imagined work taking place in space. The conversation soon started to balloon out beyond something that should be confined to the next five to ten years. However, the proposal was ruled out as work in space is not realistic from the demand perspective.

![]() We also had a number of ideas for a range of other things such as soil-regenerating machinery for abandoned farmland, amphibious equipment, and other products which could be used in the case of a disaster. However, we all ultimately agreed that none of these ideas qualified as “construction equipment”. In the end, we decided to refocus our efforts on “preserving our DNA that has helped us pioneer the manufacturing of small construction equipment”.

We also had a number of ideas for a range of other things such as soil-regenerating machinery for abandoned farmland, amphibious equipment, and other products which could be used in the case of a disaster. However, we all ultimately agreed that none of these ideas qualified as “construction equipment”. In the end, we decided to refocus our efforts on “preserving our DNA that has helped us pioneer the manufacturing of small construction equipment”.

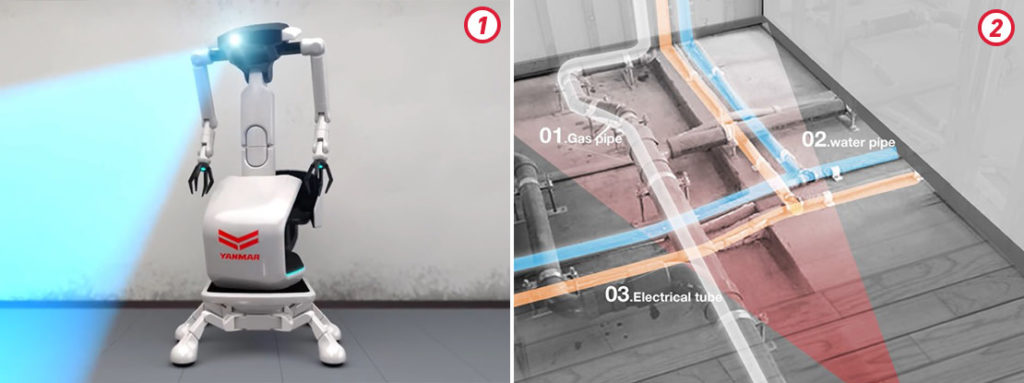

The overview of “Y-RENOVATOR” Advanced Concept Construction Equipment reducing the workload and maximizing the efficiency

Planner Unit: Reroofs ceilings/repapers the walls and carries out other delicate tasks while simultaneously controlling the Sub unit.

Sub Unit: Handles tasks such as floor stripping, transporting materials and waste, and sorting materials by type.

The Sub unit (left) can be easily used for floor stripping by using the floor stripping attachment. With the utilization of resources in mind, the Sub unit has been designed to automatically sort waste materials by type, helping reduce the workload associated with sorting tasks. The feet of both the units (right) are ball-shaped to allow movement in any direction without damaging the floor. They are also six-legged just like an insect.

Their design was finalized after a lot of trial and errors. We created many rough drafts of their design, some of which are

![]() Okay, I think we now have a better understanding of the concept and its main characteristics. Other than what you have already mentioned, are there any other important points you would like to mention?

Okay, I think we now have a better understanding of the concept and its main characteristics. Other than what you have already mentioned, are there any other important points you would like to mention?

![]() When we ask the customers to share what they feel about the product, they give suggestions like “the legs of the product should be made a little bit stronger”. After all, riding comfort is one of the important parameters they use to judge the product, even though it is their personal opinion and may change from person to person. As an equipment manufacturer, we have the onus of respecting their feelings in delivering a product that makes the ride a joyful one and does not compromise the comfort of the operator.

When we ask the customers to share what they feel about the product, they give suggestions like “the legs of the product should be made a little bit stronger”. After all, riding comfort is one of the important parameters they use to judge the product, even though it is their personal opinion and may change from person to person. As an equipment manufacturer, we have the onus of respecting their feelings in delivering a product that makes the ride a joyful one and does not compromise the comfort of the operator.

I am happy to say that the thought

“Yanmar creates what people look forward to” of President Seto

has been instilled on the minds of our young employees

Lastly, Kotaro, the interviewer for this article,

shares his impressions.

![]() I knew of Yanmar as the industry pioneer in the manufacturing of compact construction equipment. I joined the company knowing its strength as a developer of compact construction equipment that can be used to work in confined spaces of renovation project sites. But I was flabbergasted by the level of technology that goes into the making of our products.

I knew of Yanmar as the industry pioneer in the manufacturing of compact construction equipment. I joined the company knowing its strength as a developer of compact construction equipment that can be used to work in confined spaces of renovation project sites. But I was flabbergasted by the level of technology that goes into the making of our products.

I also find myself immensely interested in creating new forms of demand. I wish to follow the footsteps of my seniors by delivering products that would make our customers happy by anticipating the customers’ needs.

A video of the “Y-RENOVATOR” concept construction equipment

The manufacturing DNA of Yanmar Construction Equipment

has taken root in its young employees as well and has been nurtured to ensure a prosperous future for the company.

Yanmar Construction Equipment will continue

to find ways to offer new forms of value to its customers,

in order to build a foundation of enriched life.