Amid the increasingly severe conditions faced by Japanese agriculture, Yanmar set about a new challenge; this one from the skies. Namely, the optimization of rice cultivation using remote sensing technology. Using drones to understand and analyze the state of development of rice crops from the sky. Then utilizing the results to allow the optimum quantity of supplementary fertilizer to be scattered; an initiative to help keep the rice in its best condition. With drones at the forefront, we aim to make use of ICT to enliven Japanese agriculture.

With the goal in mind of developing this technology and system, known as remote sensing, five companies, including Yanmar, formed a consortium. “ISSA Yamagata (Imaging System for Smart Agriculture),” is the name of that consortium, formed by Konica Minolta Inc., Yamagata University’s Department of Agriculture, Tsuruoka Green Farm Co. Ltd., Ito Electronic Co. Ltd., and finally Yanmar Heli & Agri Co. Ltd. A project that would make use of all five companies’ respective fortes was born.

Exactly how did the consortium come to be formed? Specifically speaking, just what kind of technology is remote sensing? What is the future of agriculture as imagined by this consortium?

On this occasion, Konica Minolta Inc. and Yanmar Heli & Agri Co. Ltd.—the two companies in charge of the technical side of things—have sent two representatives each to talk to us about the particulars.

Konica Minolta Inc. Business Development Head Office, Head of Business Promotion Masanori Miura

Konica Minolta Inc. Business Development Head Office, Head of Business Promotion Masanori Miura

Konica Minolta Inc. Business Development Head Office, Business Promotion,3rd Promotion Group Yasushi Hoshino

Konica Minolta Inc. Business Development Head Office, Business Promotion,3rd Promotion Group Yasushi Hoshino

Yanmar Heli & Agri Co. Ltd. CEO Eiichi Ozaki

Yanmar Heli & Agri Co. Ltd. CEO Eiichi Ozaki

Yanmar Heli & Agri Co. Ltd. Managing Director of Sales Department, Technical Services Division Leader Mahiro Nagata

Yanmar Heli & Agri Co. Ltd. Managing Director of Sales Department, Technical Services Division Leader Mahiro Nagata

How the Consortium Came to be Established After a Sequence of Chance Events

— Thank you for taking the time to be with us here today. As I understand it, this will be the third and final year of this project, began in 2014 after being designated by the Ministry of Agriculture, Forests, and Fisheries as a “Leading Edge Model Agricultural Enterprise formed from the Cooperation of the Agricultural and Financial Worlds.” I can see that everyone is already well acquainted with each other; so how exactly did you all come to meet?

Everything began in the summer of 2014 when I received a proposition from Hiroshi Fuji, a professor at Yamagata University. He asked me if we could adapt our chlorophyll measuring device (SPAD*) to be usable with a camera. Now this device was something that our company had developed in order to measure the developmental condition of wetland rice. SPAD was used widely in the agricultural world, but using it was a time-consuming process of applying the terminal to individual leaves one by one. If we could use a camera to take readings from the sky, wouldn’t it be convenient? So we spoke to Yanmar Heli & Agri Co. Ltd., who are specialists in helicopters and agriculture, and they were interested right away.

Everything began in the summer of 2014 when I received a proposition from Hiroshi Fuji, a professor at Yamagata University. He asked me if we could adapt our chlorophyll measuring device (SPAD*) to be usable with a camera. Now this device was something that our company had developed in order to measure the developmental condition of wetland rice. SPAD was used widely in the agricultural world, but using it was a time-consuming process of applying the terminal to individual leaves one by one. If we could use a camera to take readings from the sky, wouldn’t it be convenient? So we spoke to Yanmar Heli & Agri Co. Ltd., who are specialists in helicopters and agriculture, and they were interested right away.

Our current unmanned-helicopter pest control operation covers approximately 40% (totaling one million hectares) of Japan’s rice fields. From before, we had had the idea that if we mounted a camera onto the helicopter, we should be able to get a clearer understanding of the status of the fields. However, we did not have sufficient expertise in the field of optics, and it was while we were thinking of a way forward that Mr. Hoshino got in touch with us.

Our current unmanned-helicopter pest control operation covers approximately 40% (totaling one million hectares) of Japan’s rice fields. From before, we had had the idea that if we mounted a camera onto the helicopter, we should be able to get a clearer understanding of the status of the fields. However, we did not have sufficient expertise in the field of optics, and it was while we were thinking of a way forward that Mr. Hoshino got in touch with us.

So then we got talking, and “Let’s get on with this straight away!”, was basically how it ended up. And one more thing was that, at that end of that year, the MAFF (Ministry of Agriculture, Forestry, and Fisheries) was offering support for enterprises relating to remote sensing, so our company was probing the possibilities of applying. Projects using ICT to cut down costs in agricultural production were exactly what we were looking for. So Yanmar, along with Prof. Fuji, applied in February 2014 and were accepted.

So then we got talking, and “Let’s get on with this straight away!”, was basically how it ended up. And one more thing was that, at that end of that year, the MAFF (Ministry of Agriculture, Forestry, and Fisheries) was offering support for enterprises relating to remote sensing, so our company was probing the possibilities of applying. Projects using ICT to cut down costs in agricultural production were exactly what we were looking for. So Yanmar, along with Prof. Fuji, applied in February 2014 and were accepted.

Yanmar were already thinking that “If we can load a camera on a helicopter…” , so the offer from the MAFF came at the perfect time. It was really a set of happy coincidences. For us, there was a desire to make a contribution to the sustainability of our food, from which we had targeted agriculture for new business, so it was the perfect chance.

Yanmar were already thinking that “If we can load a camera on a helicopter…” , so the offer from the MAFF came at the perfect time. It was really a set of happy coincidences. For us, there was a desire to make a contribution to the sustainability of our food, from which we had targeted agriculture for new business, so it was the perfect chance.

Speaking of chance, about the time when we applied for to the MAFF, we joined with Tsuruoka Green Farm, who operated our pest control helicopters. That their farmland happened to be right next to Yamagata University was quite the unexpected coincidence (Laughing).

Speaking of chance, about the time when we applied for to the MAFF, we joined with Tsuruoka Green Farm, who operated our pest control helicopters. That their farmland happened to be right next to Yamagata University was quite the unexpected coincidence (Laughing).

※The chlorophyll measuring device SPAD is a product developed by Konica Minolta 20 years ago. It uses light to measure the quantity of chlorophyll in a leaf. The quantity of chlorophyll is vital to understanding the state of development of rice plants, and this quantity, measured by the SPAD, is called the SPAD Value. Using this value to measure the state of growth of a rice plant, and to decide in accordance with it how much fertilizer to add has become an industry standard.

First Year Failures, and a Strong Recovery

The Successful “Visualization” of Agriculture in Year Two

— So by coincidence, or perhaps I should call it fate, you came together. Now your consortium was established, but what kind of goals were put forward?

We were given a 3 year period from 2014 to 2016. In that time, we had to become able to measure and put in numerical figures the rice crops’ chlorophyll status, and from that “visualize” their developmental status in areas, each a square several meters wide. Then, in accordance with those values, to apply the appropriate quantity of fertilizer in order to increase the quality and yield of rice; that was the goal we were aiming for. Of course, nothing like replicating SPAD measurements with aerial camera photography, nor precisely fertilizing each area separately from the air, had ever been done before; it was only natural that there would be many technological hurdles.

We were given a 3 year period from 2014 to 2016. In that time, we had to become able to measure and put in numerical figures the rice crops’ chlorophyll status, and from that “visualize” their developmental status in areas, each a square several meters wide. Then, in accordance with those values, to apply the appropriate quantity of fertilizer in order to increase the quality and yield of rice; that was the goal we were aiming for. Of course, nothing like replicating SPAD measurements with aerial camera photography, nor precisely fertilizing each area separately from the air, had ever been done before; it was only natural that there would be many technological hurdles.

As regards remote sensing, until now there have been examples using satellites, but as they would be affected by clouds and weather, it was seen as being difficult to implement from a business perspective. However, low-flying unmanned helicopters are unaffected by clouds. And so, we thought that if we could provide a total solution that not only made possible the visualization of the crops developmental status, but also offered both the agricultural equipment and the know-how needed to take the necessary action based on that data, then we could make it work as a business. There, it was decided that Konica Minolta would take care of the data collection by remote sensing, and we would develop the technology to enable the spreading of fertilizer in accordance with that data.

As regards remote sensing, until now there have been examples using satellites, but as they would be affected by clouds and weather, it was seen as being difficult to implement from a business perspective. However, low-flying unmanned helicopters are unaffected by clouds. And so, we thought that if we could provide a total solution that not only made possible the visualization of the crops developmental status, but also offered both the agricultural equipment and the know-how needed to take the necessary action based on that data, then we could make it work as a business. There, it was decided that Konica Minolta would take care of the data collection by remote sensing, and we would develop the technology to enable the spreading of fertilizer in accordance with that data.

— So did development progress smoothly from the beginning?

In the first year there were numerous problems. For example, at first, we thought to attach a camera to Yanmar’s pest control helicopters and take pictures like that, but it was no good.

In the first year there were numerous problems. For example, at first, we thought to attach a camera to Yanmar’s pest control helicopters and take pictures like that, but it was no good.

The rotor blades on our pest control helicopters are 3.8 meters long. The air forced underneath them in when flying is too great; the gusts generated caused the rice plants to thrash about which prevented us from obtaining usable images That’s when we decided to try using drones. Apart from the issue of wind, from a usability point of view, drones offered a greater degree of freedom. However, as drones can only fly for short periods of time and are not very strong, we made a fairly unreasonable request of Konica Minolta and had them wrestle with making the cameras more lightweight.

The rotor blades on our pest control helicopters are 3.8 meters long. The air forced underneath them in when flying is too great; the gusts generated caused the rice plants to thrash about which prevented us from obtaining usable images That’s when we decided to try using drones. Apart from the issue of wind, from a usability point of view, drones offered a greater degree of freedom. However, as drones can only fly for short periods of time and are not very strong, we made a fairly unreasonable request of Konica Minolta and had them wrestle with making the cameras more lightweight.

In 2014, using both companies preexisting technology, the combination of camera and helicopter ended in failure. Then in 2015, in order to restart experimentation, this time using drones, they worked on development through the winter. While Konica Minolta worked on making the camera more lightweight, Yanmar were developing variable fertilization—in other words, a fertilization machine capable of autonomously distributing the optimal amount of fertilizer based on the developmental status of the crop—based on the data gathered from the failed testing using helicopters in the first year.

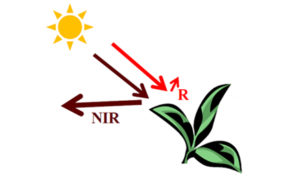

We know that the degree of absorption of red light is an indicator with which we can measure the growth status of plants. With the camera that has been developed, we can get readings on the amount of red light being reflected by the rice plants. From those readings, it was found that SPAD values could be determined. It was the first time that SPAD values had been made calculable from a camera image. Furthermore, as the number of rice stalks could now be measured as well, by combining the number of stalks with the SPAD value, the amount of nitrogen absorption can be calculated. As this figure correlates to the amount of rice harvested, by spreading additional fertilizer so that the optimal amount of nitrogen absorption takes place, rice harvests can be optimized; in short, our goal of growing the ideal rice crop can be achieved. It wouldn’t be an exaggeration to say that at the heart of what made these measurements and calculations possible is the remote sensing technology.

We know that the degree of absorption of red light is an indicator with which we can measure the growth status of plants. With the camera that has been developed, we can get readings on the amount of red light being reflected by the rice plants. From those readings, it was found that SPAD values could be determined. It was the first time that SPAD values had been made calculable from a camera image. Furthermore, as the number of rice stalks could now be measured as well, by combining the number of stalks with the SPAD value, the amount of nitrogen absorption can be calculated. As this figure correlates to the amount of rice harvested, by spreading additional fertilizer so that the optimal amount of nitrogen absorption takes place, rice harvests can be optimized; in short, our goal of growing the ideal rice crop can be achieved. It wouldn’t be an exaggeration to say that at the heart of what made these measurements and calculations possible is the remote sensing technology.

Yanmar’s unmanned helicopter, capable of fertilizing each area respectively with controlled quantities, was a world first.

On the other hand, Yanmar’s unmanned helicopter, capable of fertilizing each area respectively with controlled quantities, was a world first. This plan for variable fertilization also required advanced technology.

— Now, Rice is planted in May and harvested between September and October. If you are going to analyze the growth of the rice plants and supplement with fertilizer, then that would have to be in around July when the rice has grown to a good size. The chance for experimentation only comes once a year. So development had to be finished during winter. And you also had a limit of three years. The pressure must have been great, was it not?

That’s right, we only had a short amount of time for development. Even so, with the assistance from our cooperative manufacturers, we pushed ahead and somehow managed to make it for May 2015. So much so that we ended up taking less than three months for production.

That’s right, we only had a short amount of time for development. Even so, with the assistance from our cooperative manufacturers, we pushed ahead and somehow managed to make it for May 2015. So much so that we ended up taking less than three months for production.

We’d move forward working together, telling them the precision of our remote sensing, and how precise we wanted Yangar’s variable fertilizing. At Yamagata University we were allowed to carry out trials of the fertilization system; in other words, trialing scenarios to learn the optimal amount of fertilizer to spread depending on the values obtained with remote sensing. Although there wasn’t much time, we somehow or other managed to get the all the technology ready for spring 2015.

We’d move forward working together, telling them the precision of our remote sensing, and how precise we wanted Yangar’s variable fertilizing. At Yamagata University we were allowed to carry out trials of the fertilization system; in other words, trialing scenarios to learn the optimal amount of fertilizer to spread depending on the values obtained with remote sensing. Although there wasn’t much time, we somehow or other managed to get the all the technology ready for spring 2015.

“Sensing Goes from Points to Areas. As Action Goes from Areas to Points”

Fertilization Tailored to Each Farm’s Needs Becomes a Possibility

— So as a result of each companies endeavors, by the spring of 2015, the second year, everything was in place to begin experimentation in earnest. So how were the results?

For our testing, we used two varieties of rice, “Haenuki” and “Tsuyahime,” and the results came out as planned. “Haenuki” is a type of rice widely used in the food-service industry; to farmers, there is more to be gained by increasing yields rather than quality. To those ends, we carried out variable fertilization focused on increasing yields, which resulted in a 14% larger harvest. On the other hand, “Tsuyahime” is a brand rice where more importance is placed on quality. Configuring our trials with that goal in mind, although yields decreased, the quality of the rice was improved. As a result, the farms were able to sell the rice at a high price and increase revenue by 33%. Those results gave us some confidence.

For our testing, we used two varieties of rice, “Haenuki” and “Tsuyahime,” and the results came out as planned. “Haenuki” is a type of rice widely used in the food-service industry; to farmers, there is more to be gained by increasing yields rather than quality. To those ends, we carried out variable fertilization focused on increasing yields, which resulted in a 14% larger harvest. On the other hand, “Tsuyahime” is a brand rice where more importance is placed on quality. Configuring our trials with that goal in mind, although yields decreased, the quality of the rice was improved. As a result, the farms were able to sell the rice at a high price and increase revenue by 33%. Those results gave us some confidence.

The important thing was to be able to meet the demands of the varying cultivation strategies. Once the amount of protein in the rice goes above a certain level, the taste begins to worsen. There for example, if one farm wants to increase their revenues by restricting the protein content and creating high-quality rice, while another wishes to increase yields of a generic rice while allowing for some increase in protein content, then we hoped to be able to control fertilization to match those plans. We could see the path to the realization of our goals.

The important thing was to be able to meet the demands of the varying cultivation strategies. Once the amount of protein in the rice goes above a certain level, the taste begins to worsen. There for example, if one farm wants to increase their revenues by restricting the protein content and creating high-quality rice, while another wishes to increase yields of a generic rice while allowing for some increase in protein content, then we hoped to be able to control fertilization to match those plans. We could see the path to the realization of our goals.

Another big difference is that until now, remote sensing could only offer relative values about growth status. With the algorithm that Konica Minolta developed, we could understand in absolute values the condition of growth.

Another big difference is that until now, remote sensing could only offer relative values about growth status. With the algorithm that Konica Minolta developed, we could understand in absolute values the condition of growth.

In short, until this point, although we could determine the status of growth, we couldn’t answer the question of how much fertilizer should be added. But now, with the algorithm that we have developed, we can understand it with a figure, say, “Here corresponds to a SPAD Value of 38.” Then in the deficient area, we would know to supplement with an additional two kilos of fertilizer; that’s the kind of specific action that it connects to.

In short, until this point, although we could determine the status of growth, we couldn’t answer the question of how much fertilizer should be added. But now, with the algorithm that we have developed, we can understand it with a figure, say, “Here corresponds to a SPAD Value of 38.” Then in the deficient area, we would know to supplement with an additional two kilos of fertilizer; that’s the kind of specific action that it connects to.

— So the results of the experimental trials went as you hoped. I’m sure that you must have made some new discoveries when you first tried it out in practice.

Yes, there was a big discovery. Just by visualizing the growth status of the rice crop, we could gather much information about the condition of a field. Looking at the visualization, the trails of where the fertilizer had been spread were clear. Showing this to Yanmar, for example, they could understand things like “Ah, this area has been insufficiently fertilized.” That was a big surprise.

Yes, there was a big discovery. Just by visualizing the growth status of the rice crop, we could gather much information about the condition of a field. Looking at the visualization, the trails of where the fertilizer had been spread were clear. Showing this to Yanmar, for example, they could understand things like “Ah, this area has been insufficiently fertilized.” That was a big surprise.

Also, there was a case where a certain location within a field was showing poor growth. When we asked the farmer about it he said, “Ah, there is hardpan there, they always grow poorly.” In other words, just by looking at our map, we could locate areas of hardpan. Which meant it could be used in land improvement as well. At first, we believed that there would be no meaning in just the visualization itself, but now we realized how greatly valuable it was.

Also, there was a case where a certain location within a field was showing poor growth. When we asked the farmer about it he said, “Ah, there is hardpan there, they always grow poorly.” In other words, just by looking at our map, we could locate areas of hardpan. Which meant it could be used in land improvement as well. At first, we believed that there would be no meaning in just the visualization itself, but now we realized how greatly valuable it was.

Until now, a large part of agriculture has depended on intuition and experience; “scientific measurements” didn’t play a large role. It’s because of this that I believe that our success in displaying the developmental status of rice crops as numerical values, thanks to Konica Minolta’s technology, will have a large impact on the future of agriculture.

Until now, a large part of agriculture has depended on intuition and experience; “scientific measurements” didn’t play a large role. It’s because of this that I believe that our success in displaying the developmental status of rice crops as numerical values, thanks to Konica Minolta’s technology, will have a large impact on the future of agriculture.

But even if we could measure values, if we cannot prove their significance, then it would be worthless. It was there that being partnered with agricultural specialists Yanmar allowed us to link our work to practical results.

But even if we could measure values, if we cannot prove their significance, then it would be worthless. It was there that being partnered with agricultural specialists Yanmar allowed us to link our work to practical results.

So we got thinking about if we could express our results and discoveries in a single phrase, and came up with this catchphrase. “Sensing Goes from Points to Areas. As Action Goes from Areas to Points.” Compared with how up until now whole areas of rice crop would be treated with the same action based upon estimates which had been made from the data of a few points, with our current technology, we can gather precise data of the whole area and from there take finely tuned action at each point within. That process is connected to optimization, and we believe that it will prove to be an important ally to farmers.

So we got thinking about if we could express our results and discoveries in a single phrase, and came up with this catchphrase. “Sensing Goes from Points to Areas. As Action Goes from Areas to Points.” Compared with how up until now whole areas of rice crop would be treated with the same action based upon estimates which had been made from the data of a few points, with our current technology, we can gather precise data of the whole area and from there take finely tuned action at each point within. That process is connected to optimization, and we believe that it will prove to be an important ally to farmers.

Fellow Tech Businesses Cooperating and Learning from Each Other

Contributing to Japan’s and Agriculture’s Future with Sensing Technology

— Seeing you all talking, I can feel how much both your companies respect each other. I wonder if your respective experiences of cooperating with tech businesses from differing industries had any effect on you?

It was my first time working together with a company involved in electronics and optics. As you would expect with working in a different industry, the thought processes and approach to development are quite different. In the first place, we even differed in how we defined precision agriculture. Konica Minolta defined it to be controlling spaces, each a size in the range of a few tens of centimeters, whereas we thought of it in units of meters. But that kind of difference in feeling felt very fresh, I really learned a lot from them.

It was my first time working together with a company involved in electronics and optics. As you would expect with working in a different industry, the thought processes and approach to development are quite different. In the first place, we even differed in how we defined precision agriculture. Konica Minolta defined it to be controlling spaces, each a size in the range of a few tens of centimeters, whereas we thought of it in units of meters. But that kind of difference in feeling felt very fresh, I really learned a lot from them.

If we talk about resolving power, then in contrast to Konica Minolta who operated in square centimeters, our limit for spreading fertilizer was in units of a meter. On the other hand, when we told farmers that fertilizer amounts can be adjusted by the square meter, they were surprised at the level of accuracy. Everyone’s perspective is different. It was a great experience to throw these differences against each other to form a discussion.

If we talk about resolving power, then in contrast to Konica Minolta who operated in square centimeters, our limit for spreading fertilizer was in units of a meter. On the other hand, when we told farmers that fertilizer amounts can be adjusted by the square meter, they were surprised at the level of accuracy. Everyone’s perspective is different. It was a great experience to throw these differences against each other to form a discussion.

— How about Konica Minolta?

Until then, we had almost no knowledge about agriculture and in the beginning, even the terminology was difficult. I thought mistook the word “shussui” which refers to the appearance of ears of grain, for the word “shussui” which referred to floods (laugh). I had the opportunity to learn many of these basic things. We would like to develop business in the field of agriculture in the future, and having the chance to work with such a wonderful partner in Yanmar was a truly valuable experience.

Until then, we had almost no knowledge about agriculture and in the beginning, even the terminology was difficult. I thought mistook the word “shussui” which refers to the appearance of ears of grain, for the word “shussui” which referred to floods (laugh). I had the opportunity to learn many of these basic things. We would like to develop business in the field of agriculture in the future, and having the chance to work with such a wonderful partner in Yanmar was a truly valuable experience.

From this experience, we realized that to enter into the world of agriculture, we need to partner with experts of the field. Yanmar already has a wide variety of connections in the world of agriculture. From the perspective that many of these connections may become our customers, we are very thankful for this opportunity.

From this experience, we realized that to enter into the world of agriculture, we need to partner with experts of the field. Yanmar already has a wide variety of connections in the world of agriculture. From the perspective that many of these connections may become our customers, we are very thankful for this opportunity.

— This consortium is going to end at the end of this year, correct? This conversation though, it sounds like it has a future. Could you please tell me about your future vision and any other thoughts or feelings you would like to share?

There is the saying, “No measurement, no improvement”. Agriculture has relied on intuition and experience up until now, but this time, we were able to understand the usefulness of sensing in measurement. From now on, it is my wish to apply this method and measure everything as much as possible, including for the diagnosis of disease in fields. I am sure that it will contribute to the advancement of agriculture.

There is the saying, “No measurement, no improvement”. Agriculture has relied on intuition and experience up until now, but this time, we were able to understand the usefulness of sensing in measurement. From now on, it is my wish to apply this method and measure everything as much as possible, including for the diagnosis of disease in fields. I am sure that it will contribute to the advancement of agriculture.

Agriculture is a field which our company always wanted to become involved in. By working together with Yanmar this time, I feel like I was able to create a mechanism for a system that can contribute to the future of agriculture. Although we are still at the start line, in the future, I hope we can develop this system further in order to solve or ease agricultural issues by even a little.

Agriculture is a field which our company always wanted to become involved in. By working together with Yanmar this time, I feel like I was able to create a mechanism for a system that can contribute to the future of agriculture. Although we are still at the start line, in the future, I hope we can develop this system further in order to solve or ease agricultural issues by even a little.

— Finally, how about Yanmar?

Continuing to take growth condition measurements every year will eventually lead to big data. By combining it with the data of the Japan Meteorological Agency, for example, we may be able to predict what conditions may arise if it rains two days from now. Agriculture will definitely advance to robotics in the future. When that time comes, robots will need to know the conditions of the fields in order to take accurate actions. I feel that this new technology will become a foundation for this process.

Continuing to take growth condition measurements every year will eventually lead to big data. By combining it with the data of the Japan Meteorological Agency, for example, we may be able to predict what conditions may arise if it rains two days from now. Agriculture will definitely advance to robotics in the future. When that time comes, robots will need to know the conditions of the fields in order to take accurate actions. I feel that this new technology will become a foundation for this process.

The average age of farmers in Japan is currently about 67 years old. Moreover, the farming population has not been able to keep pace with the population of farmers leaving the industry. On the other hand, agriculture, which bears the burden of supplying food in Japan, is still important as a key industry, and we must ask young people to carry on this responsibility. With this technology, cultivation management based on scientific data is carried out, and I think it can help to create an environment where farmers can continue agriculture with confidence by further improving efficiency.

The average age of farmers in Japan is currently about 67 years old. Moreover, the farming population has not been able to keep pace with the population of farmers leaving the industry. On the other hand, agriculture, which bears the burden of supplying food in Japan, is still important as a key industry, and we must ask young people to carry on this responsibility. With this technology, cultivation management based on scientific data is carried out, and I think it can help to create an environment where farmers can continue agriculture with confidence by further improving efficiency.

— Hearing your stories, I feel like I understand your thoughts on this technology, the future of agriculture, and your strong feelings towards Japan’s future. I look forward to further development in the future. Thank you for sharing your precious stories today!

A consortium where different technology companies, universities and farmers have worked on co-creating. We delivered the dialogue between two companies that led the technical aspects. From the start of the project, to the discoveries during the experiment, and the certain results. As a technology supporting agricultural management, the day when remote sensing agriculture spreads nationwide may not be so far.

Next time we will move the location to Yamagata, where the experiments were done. From the interview of Yamagata University and Tsuruoka Green Farm, we will further “visualize” the value and possibilities of this initiative!