News Release

Full-scale commencement of distributed power supply model business through biomass gasification power generation utilizing rice husks in Myanmar

March 23, 2017

YANMAR CO., LTD.

YANMAR CO., LTD. has completed construction of a local testing plant in order to commence verification testing of biomass gasification power generation using rice husks in the Republic of Myanmar capital of Naypyidaw. The plant began full-scale operation on March 23 as a verification testing facility for distributed power generation established parallel to rice mills.

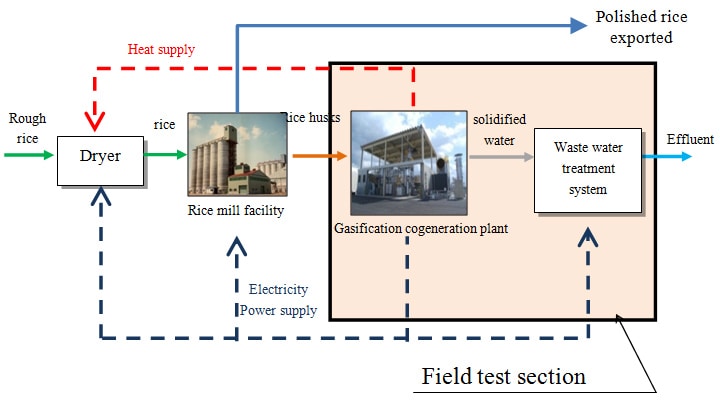

We have constructed a biomass gasification power generation plant which utilizes the large quantities of rice husks generated every year on the premises of a rice mill operated by local company MAPCO (Myanmar Agribusiness Public Corporation). This plant uses the husks from rice grown and harvested locally as fuel for a gasification power generation system which in turn provides power for the rice mill facility and water treatment equipment. The cogeneration units that make up the distributed power supply will also supply heat to the facility. It is expected that the use of this power plant using rice husks generated from the rice mill facility will eventually be able to supply all the power required for the rice mill facility. In addition, the plant also contributes to environmental preservation by reducing CO2 compared to conventional power supplies. The success of this verification test will lead to greater adoption of this generation system not just in Myanmar, but throughout Southeast Asia, and help ensure a future free from interruptions in power delivery.

In addition, in February 2017, we also established the local subsidiary YANMAR MYANMAR CO., LTD. in the city of Yangon (Thilawa Special Economic Zone) in order to contribute to the mechanization of Myanmar's agriculture. The new subsidiary will coordinate with our company's other bases in Myanmar and work to create high added value for local agriculture and contribute to resource recycling model food production and distribution.

Going forward, we aim to construct a resource recycling model food supply chain in Myanmar by propagating the environmentally friendly distributed power supply system.

■Rice husk gasification power generation system verification project

- Location: On the premises of the MAPCO rice mill facility at Mezligon Village Plot No1669 in the capital of Myanmar Naypyidaw (Plot No.1669, Mezligon Village, Pyinmana Township, Nay Pyi Taw)

- Project period: November 2015 to March 2018

- Power generation output: 300 kW under normal conditions (500 kW maximum)

■Power generation plant flow outline

- Rice husks generated from the rice mill (20 t per day) are sent to storage hoppers, and gasified in the gasification furnaces inside the power plant.

- The produced gas is refined through filtration, etc. and cooled, then used as fuel for a co-generation system.

- The power generated by the co-generation system is then supplied as fuel for the rice mill facility.

- The waste heat generated during power generation is used as heat supply for unhulled rice dryers. In addition, the rice husk char (residue) emitted when combusting the rice husks includes fertilizer components, and is used to fertilize agricultural fields, also contributing to resource recycling model agriculture. In addition, waste water treatment testing is also being carried out, all to construct an environmentally friendly system.

- ※This verification project is being carried out with support from the Ministry of the Environment "Low Carbon Technology Innovation Project for Developing Countries".

<About YANMAR>

With beginnings in Osaka, Japan in 1912, YANMAR was the first ever to succeed in making a compact diesel engine of a practical size in 1933. Moving on, with industrial diesel engines as the cornerstone of the enterprise, YANAMR has continued to expand its product range, services, and expertise to deliver total solutions as an industrial equipment manufacturer. As a provider of small and large engines, agricultural machinery and facilities, construction equipment, energy systems, marine, machine tools, and components — YANAMR’s global business operations span seven domains.

On land, at sea, and in the city, YANMAR’s Mission of “providing sustainable solutions focused on the challenges customers face, in food production and harnessing power, thereby enriching people’s lives for all our tomorrows,” stands testament to YANMAR’s determination to providing us with “A SUSTAINABLE FUTURE.” For more information, visit YANMAR CO., LTD. at its global website at https://www.yanmar.com/global/about/.

[Inquiries related to this content]

Public Relations Group

Brand Communication Division, Yanmar

E-mail: koho@yanmar.com

- Note: Information contained in the news release is valid at the time of publication and may differ from the most recently available information.