Examples of engine failures caused by insufficient maintenance - Industrial Engines

Performing regular maintenance according to the product usage prevents breakdowns and serious accidents, and will reduce running costs.

This is what may happen if you do not perform regular maintenance to your YANMAR product.

YANMAR recommends regular maintenance to prevent breakdowns and to ensure that the product can be used for a longer period of time.

We recommend to have regular inspections and maintenance carried out by professional service staff, so please contact your nearest dealer.

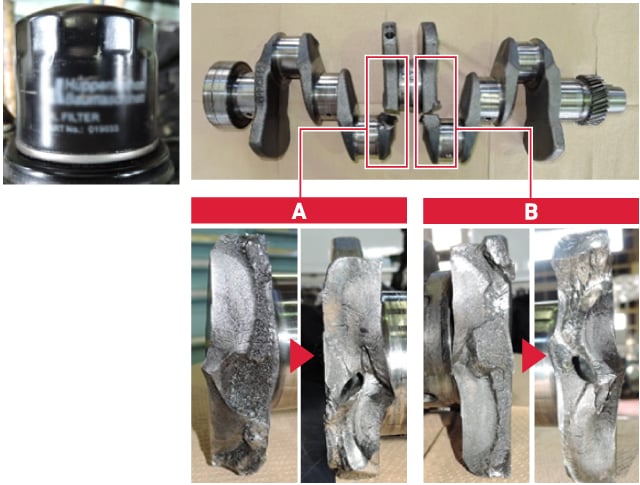

CASE 01. Prolonged use of engine oil and lubrication oil filters

Crank damage - 1

(1) The metal particles in the engine oil were not filtrated by oil filter, and the contaminated engine oil was supplied to the sliding part of the crankshaft.

(2) As the frictional resistance of the sliding part of the crankshaft increased, the pin bearing suffered from burn-in.

(3) As the crankshaft broke during operation, other parts were also damaged.

Crank damage - 2

(1) As metal particles accumulated inside the engine, the journal metal burnt in, and the crankshaft broke.

(2) As the crankshaft broke while the engine was in operation, other parts were also damaged.

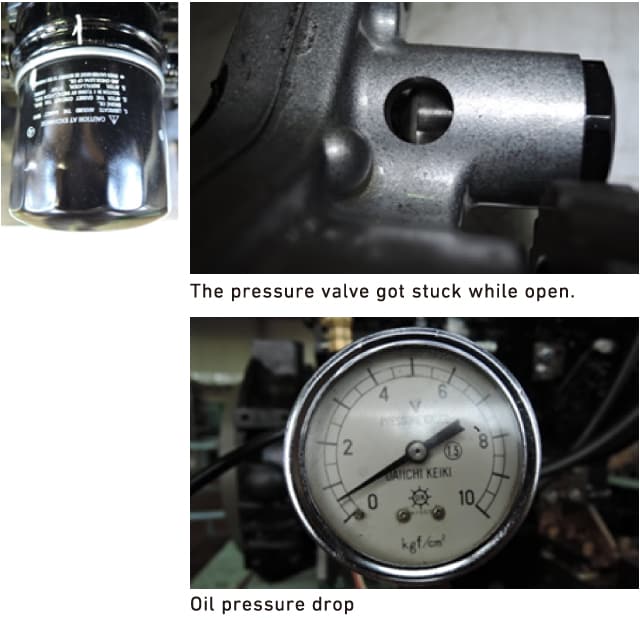

Abnormal drop in oil pressure

(1) The metal particles in the engine oil were not filtered out by the oil filter, and the contaminated engine oil entered the lubrication oil pump.

(2) Metal particles entered the pressure valve of the pump, and the valve remained open. As a result, oil pressure dropped.

(3) Engine oil did not flow to the moving parts, causing friction. This resulted in burn-in of the engine.

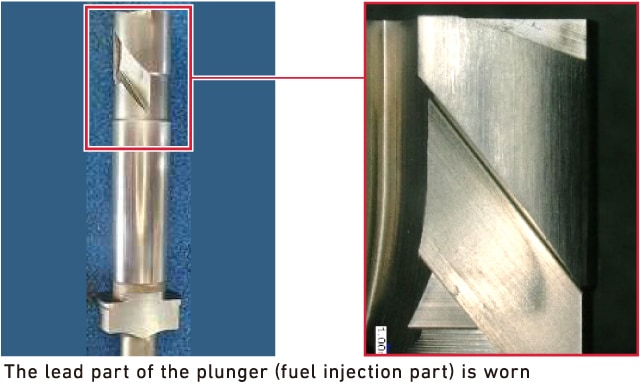

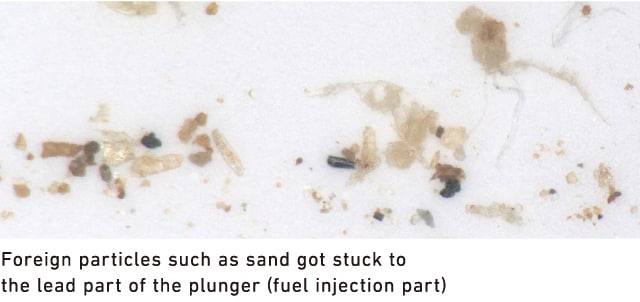

CASE 02. Prolonged use of fuel filter

Premature wear of plunger (fuel injection part)

Foreign particles such as sand got stuck lead part of the plunger (fuel injection part), causing the engine to start poorly.

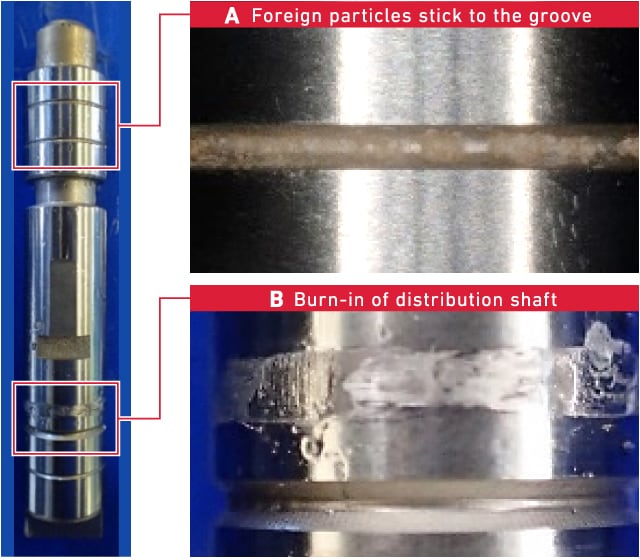

Burn-in of distribution shaft

Foreign matter sticks to the groove of the plunger (fuel injection part) and the distribution shaft was burnt-in, causing the engine to start poorly.

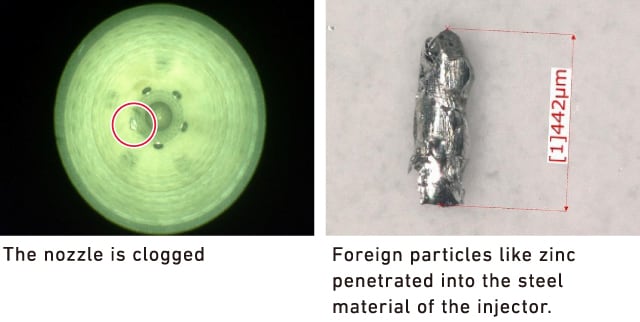

Foreign matter is penetrated into the nozzle

(1) As foreign matter is clogging up the fuel injection nozzle, fuel is not injected into the chamber properly, causing the engine to start poorly.

(2) As a result, the engine produced white smoke and abnormal noise.

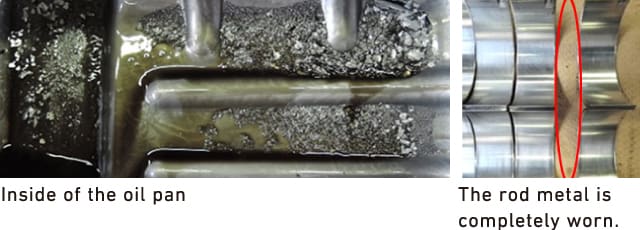

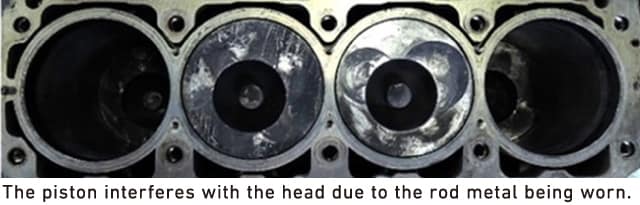

CASE 03. Insufficient lubrication

Engine burn-in

(1) The rod metal is completely worn.

(2) Due to rod metal being completely worn, the piston interferes with the head, causing the engine to malfunction.

CASE 04. Insufficient maintenance of intake valve

White smoke

(1) As the valve seat surface is worn, the air is not sufficient, resulting in poor engine combustion.

(2) As a result, the engine produced white smoke.