The outlook for agricultural management becomes clear by transforming a farmer’s intuition into organized intelligence.

Quality produce through close control of the cultivation environment for plant factories and greenhouse can be achieved through this indoor farming. Although the agricultural industry is a vital part of society which provide food for the people, many farmers face challenges in operating a profitable business due to its difficulty in making a clear forecast. Farming is heavily reliant on the intuition of experts and newcomers are reluctant to make an entry into this line of work.

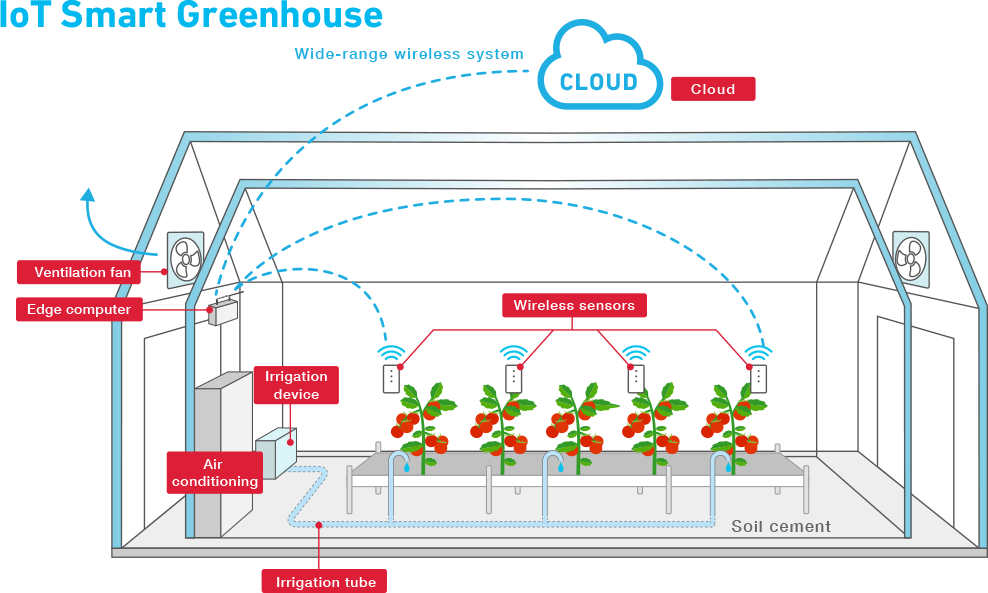

For this reason, Yanmar started a project to make farming predictable and efficient by using indoor farming called the Smart Greenhouse. This is an innovative project launched in collaboration with companies and their respective expertise to minimize the burden for farm producers and to guide them with steady production and reliable business. The users can automatically control cultivation methods by customizing the growing environment through temperature and humidity levels as well as amount of water, depending on the type of crop and cultivar. This not only helps farm producers new to the industry, but also alleviates their workload and leads to higher yield. By using data, agricultural management becomes more predictable as a business.

Agriculture

Agriculture

Combine Harvesters

Combine Harvesters

Rice Transplanters

Rice Transplanters

Marine Commercial

Marine Commercial

Compact Equipment

Compact Equipment

Industrial Engine

Industrial Engine

Recreational Marine

Recreational Marine

Energy Systems

Energy Systems

Power Generation

Power Generation

YEBISU Marine Engine

YEBISU Marine Engine