Takumi Minamino

Witnesses the

“Frontline of Zero Emissions”

and the

Future of Ships

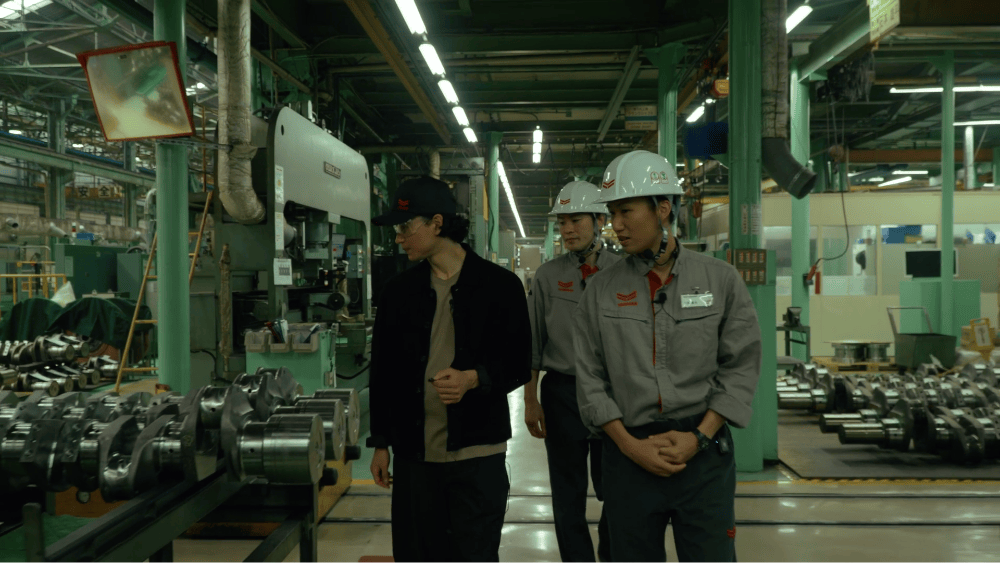

After completing a classroom session on “the future of ships and energy,” Minamino headed to the Yanmar Power Solutions Amagasaki Factory.

In this manufacturing site—where large marine engines are assembled one by one by hand—massive crankshafts, meticulous craftsmanship, and cutting-edge fuel cells designed with a zero-emission future in mind come together.

This is not merely a production line. It is a challenge to transform “the power that moves the future” into reality.

What Minamino experienced firsthand was Japanese engineering that truly embodies the force driving the future.

“Where Giant Engines Are Born” — The Pulse of the Factory Through Minamino’s Eyes

Minamino stepped into the historic Yanmar Power Solutions Amagasaki Factory, completed in 1936. Across the roughly 40,000 m2 site, facilities for everything from machining and assembly to outfitting, operational testing, and shipping are neatly arranged. More than 2,000 diesel and DF (dual-fuel) engines are produced here every year, supporting maritime transport around the world.

“Everything… is built here?”

Although the site appears analog at first glance, all process management is centrally controlled through the Order Entry System, enabling a lean and efficient production flow. This fusion of advanced technology and digital tools exemplifies the coexistence of energy efficiency and high precision—an essential foundation for sustainable manufacturing.

Immersed in the balance of quiet focus and underlying intensity, Minamino witnessed the very origins of the “power that sustains the future.”

Handcrafted One by One — The Striking Presence of Giant Crankshafts

In one area of the plant, enormous metal components lined up in perfect order. What first captured Minamino’s attention was the crankshaft.

“This… is all a single piece?”

Standing in silence, the crankshaft exuded an austere yet dignified presence. The role it plays as the “starting point of power,” forged from a massive block of steel, spoke louder than words.

“Each engine is custom-built. Unlike mass production, every unit is made to order,” explained Mr. Onishi, his voice carrying both pride and unwavering commitment.

Here, everything—technology, weight, heat, and sound—is undeniably real. Minamino sensed not only the warmth of the human hands behind each process but also the gravity of the social responsibility carried by this work.

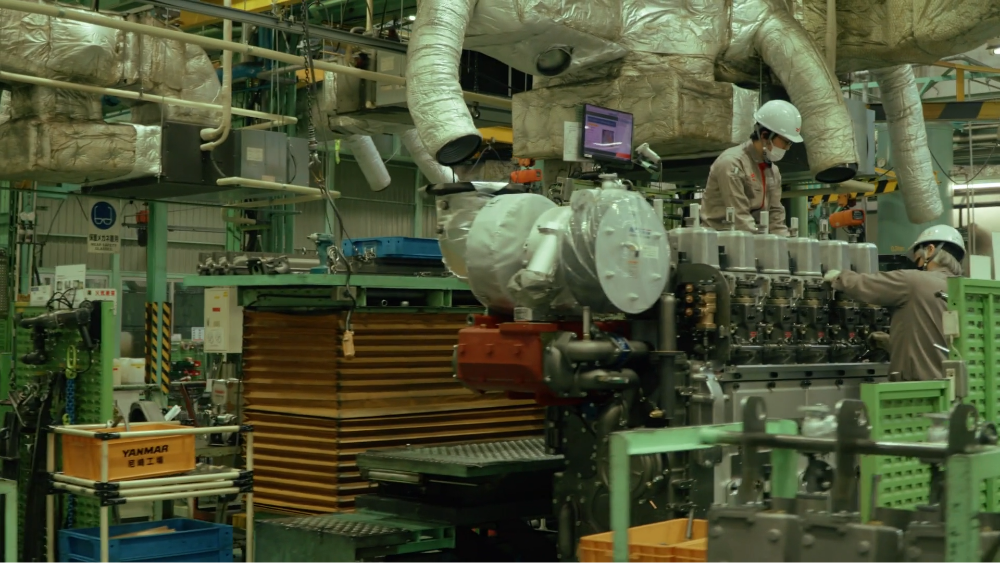

“The Moment the Inorganic Comes to Life” — The Assembly Process Where Engines Are Born

Pistons, connecting rods, and crankshafts—components that form the very source of power—are brought together and given life as a single engine. This is the core area where that transformation takes place.

Metallic sounds echo through the tall factory hall. As workers exchange focused glances, a large engine unit suspended from a crane is gently lowered into position. Even the smallest misalignment is unacceptable. Guided by precise drawings, the assembly process proceeds with confident, practiced movements.

“The up-and-down motion turns into rotation… it’s kind of like a bicycle pedal,” Minamino observed.

Mr. Hiraiwa nodded in agreement.

“That’s exactly right. The pistons move up and down, the crankshaft converts that into rotational motion, and that ultimately becomes the output power. It looks simple, but it involves a tremendous amount of sophisticated engineering and fine adjustment.”

Just as he described, the finely machined crankshaft quietly reflected the light that filled the factory.

“The Iron Heart Begins to Beat” — Minamino Witnesses the Moment of Birth

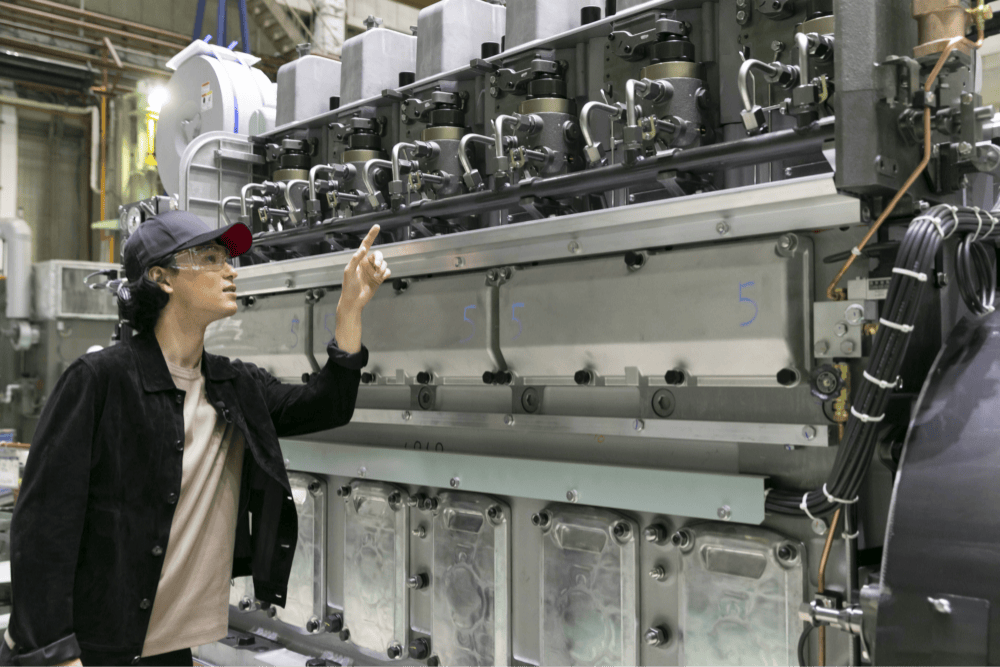

Minamino then moved to the area where the engine truly takes shape—where it gains its form and its heartbeat.

Spread before him was an area where meticulously crafted components were beginning to come together.

“This part sits just beneath the connecting rods. It transfers the explosive energy of the fuel combustion to the crank,” an engineer explained.

Workers carefully installed critical components such as the crankshaft and fuel injection pump, one piece at a time.

“About 10 units are shipped per day. They’re all made to order, so we can’t run a car-like production line,” said Mr. Onishi.

“I can’t believe how much human craftsmanship goes into this…!” Minamino remarked in astonishment.

“Imagining This Engine Running at Sea… It’s Exciting Just to Think About It.”

The engine uses an air-start system, in which compressed air is used to initiate combustion. With a maximum output of 4,800 kW—roughly 6,500 horsepower—it boasts the power equivalent to about twenty large trucks.

From there, Minamino moved on to the operational process of the large engines.

“Using the power generated by fuel combustion, the engine runs to generate electricity. In some vessels, three to four of these power-generation engines are installed,” explained Mr. Onishi.

Faced with a Massive Engine, Minamino Murmurs:

“This is practically an iron beast. And the fact that it moves…”

In an area filled with the sound of turbines, blue and red components stood out.

“This is the lubricating oil filter, and this here is the cooling unit. We also have a cooling water supply system and a hydraulic dynamometer to set a target load,” Mr. Onishi continued.

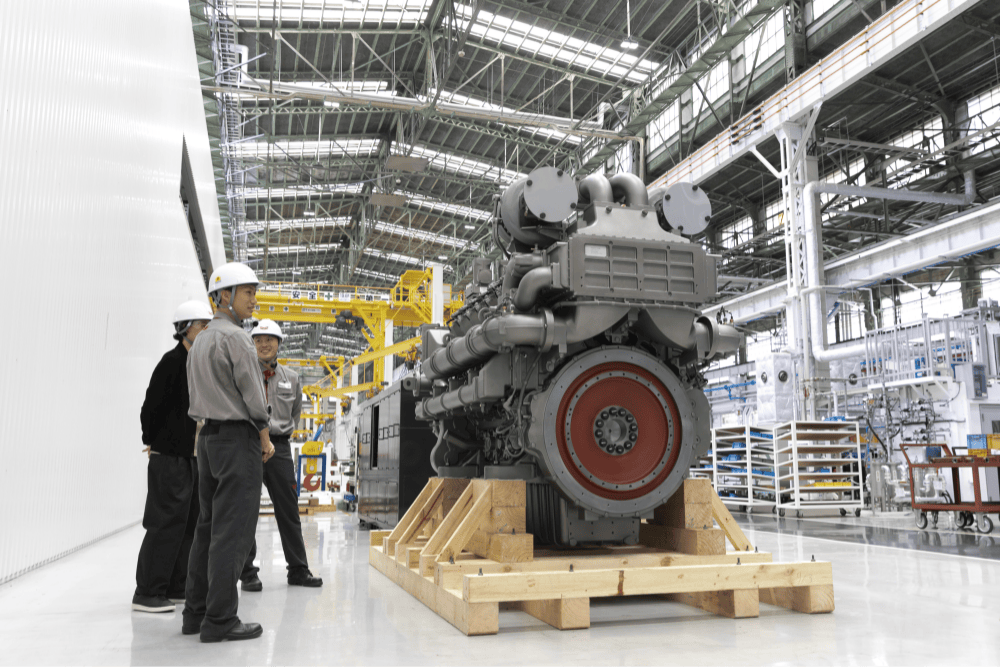

“A Breathing Brain” — The Power of a State-of-the-Art V-Type Engine

The highlight of the tour was Yanmar’s latest V-type engine—the 12GY175 diesel engine.

Its appearance was almost sculptural, like a piece of metal art.

Compared with conventional in-line engines, this model features a more compact design while achieving equal or greater output.

“This engine was unveiled in Spain and received very high praise across Europe,” Mr. Onishi said with pride.

Its output exceeds 2,000 kW.

Multiple turbochargers force air into the system, while a common-rail fuel injection system manages fuel delivery. This system enables high-pressure, multi-stage injection events with advanced electronic control, improving injection precision and resulting in excellent combustion efficiency and reduced emissions.

“This thing is practically a breathing brain,”

Minamino remarked—his words echoing through the quiet factory hall.

Despite being cold metal, the engine seemed to possess a will of its own.

Technology, expertise, and the accumulated experience of skilled craftsmen intertwined with precision, and Yanmar’s “intelligence” were embodied in this one machine.

Before long, this engine will travel across the seas, supporting global logistics and people’s everyday lives.

Beyond that lies the next step toward a cleaner, more efficient energy future.

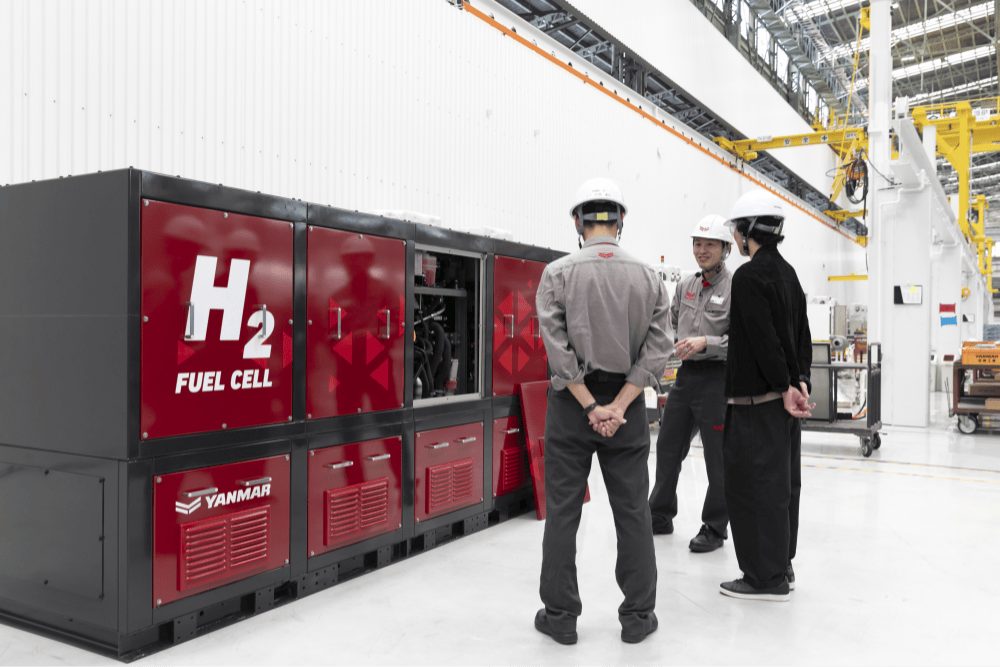

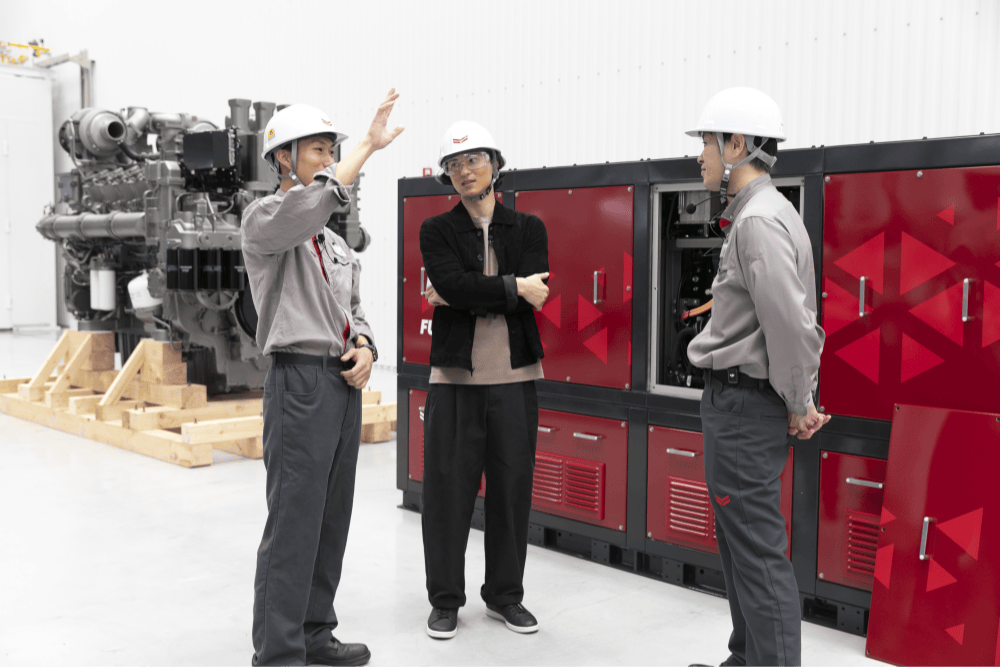

“The Core of Zero Emissions” — The True Nature of the Hydrogen Fuel Cell System

“This is our hydrogen fuel cell system, ‘FC Yanmar.’ Today, we’re giving you special access to see the inside as well.”

What appeared before Minamino was a striking red hydrogen fuel cell system, quietly stationed in a corner of the plant. Behind its panels, four black fuel cell modules were neatly arranged in a row.

The heavy, cube-shaped blocks looked almost like condensed, motionless energy.

“They really look like black blocks… Are these the actual power generators?”

Minamino asked, and both Mr. Hiraiwa and Mr. Onishi nodded.

“That’s right. They generate electricity by causing a chemical reaction between hydrogen and oxygen. The only emission is water vapor—truly zero-emission technology.”

The foundation of the system is Toyota’s fuel cell module, which Yanmar has customized to create a power-generation system designed for stable operation at sea.

“It may sound similar to a household dry battery, but the inside is completely different. Control, cooling, installation—every aspect requires highly advanced technology,” they explained.

This hydrogen fuel cell system is one of the key components of the integrated power system designed by Yanmar PT. Alongside the fuel cells, it incorporates storage batteries, power control systems, propulsion systems, and remote monitoring— achieving zero-emission operation and exceptional quietness even as a standalone unit.

Coexisting with diesel engines yet steadily evolving,

this new power source stood as a living demonstration of Yanmar’s vision for a sustainable future.

“The Hands Supporting the Future” — The Pride of the Engineers Through Minamino’s Eyes

Reflecting on the visit, Minamino shared his impressions.

“Every single process contained far more ingenuity and purpose than I imagined. The people working here aren’t just supporting the ‘power of the future’—they’re contributing directly to the future of the planet. I could truly feel their responsibility and pride.”

The hands that assemble massive engines, and the commitment infused into the fuel cells—

Yanmar’s technology and passion beat quietly, driving toward the future.

In Minamino’s gaze, he could clearly see “the future of power”—the vision of a sustainable future.

And next, in the following chapter, the story moves to Yanmar’s Technology Museum, where Minamino begins a dialogue with next generation young engineers— their words and visions of the future intersecting …