YANMAR Smart Agriculture, State-of-the-art agricultural machinery (initiatives in Japan)

Robot Tractor / Auto Tractor

“SMARTPILOT” is the name of Yanmar’s Smart Agriculture Equipment capable of automated operation.

Robot Tractors for next-level labor and manpower savings

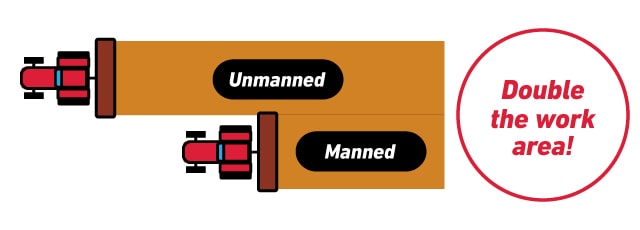

Cooperative work using multiple tractors

Enables one operator to do the work of two.

Enables one operator to do the work of two. Accurate and straight work is also possible by following the tracks of the robot tractor.

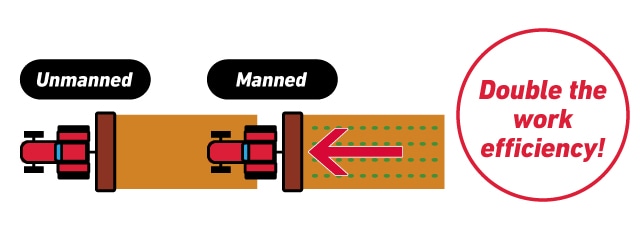

Perform multiple operations at once

Operators can now perform two separate processes simultaneously.

By enabling two continuous operations to be completed at once, operations can be optimized without being affected by weather.

Operate remotely

- Tractor work from outside the seat now possible!

- Work can be controlled just using a tablet!

- One person can complete two jobs at once by including a manned vehicle!

Automate high-precision work

- Work that previously depended upon experience and know-how can be performed with high accuracy!

- Reduces fatigue caused by long work hours!

Auto Rice Transplanter

“SMARTPILOT” is the name of Yanmar’s Smart Agriculture Equipment capable of automated operation.

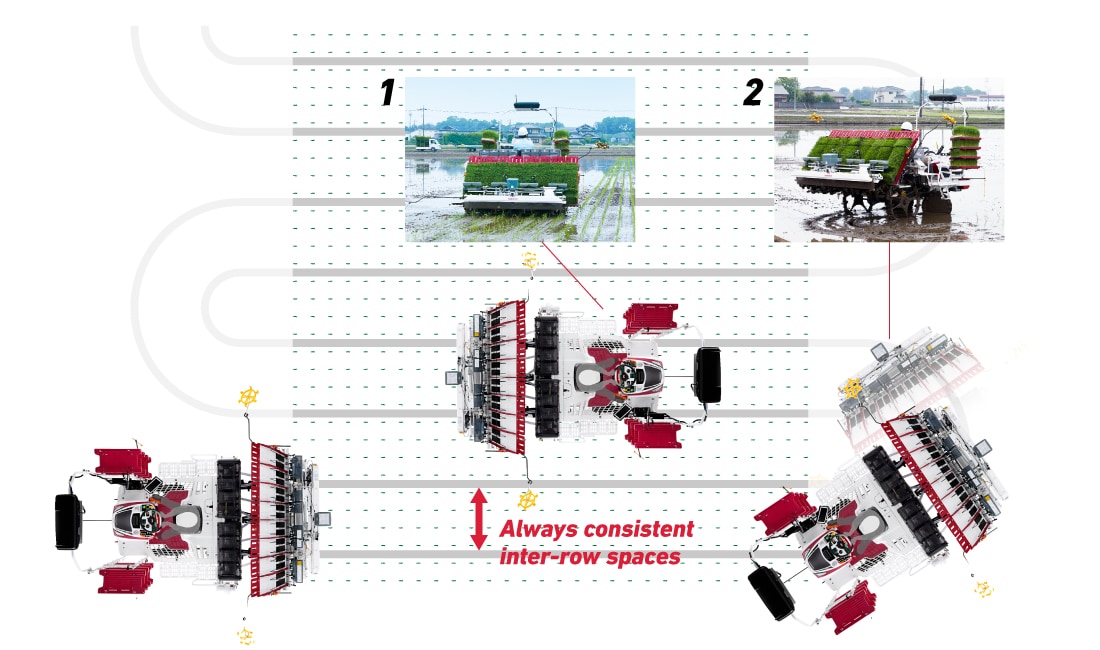

Both straight travel and turning are fully automated

These next-generation rice transplanters help farmers get hitherto laborious work done with less fatigue.

Facilitates work for both operators and their assistants

Highly accurate “automated straight travel” and “automated turning” are enabled via use of a RTK-GNSS measurement system with centimeter-level accuracy.

1. Automated straight travel

Straight planting can be performed by anyone.

2. Automated turning

Reduces fatigue caused by long work hours.

Next-level labor savings by combining auto rice transplanters with Yanmar’s Mitsunae

Through high-density transplanting of 50 to 60 stalks per every 3.3 m2, seedling boxes can be reduced to 5 to 8 boxes per 10 a.

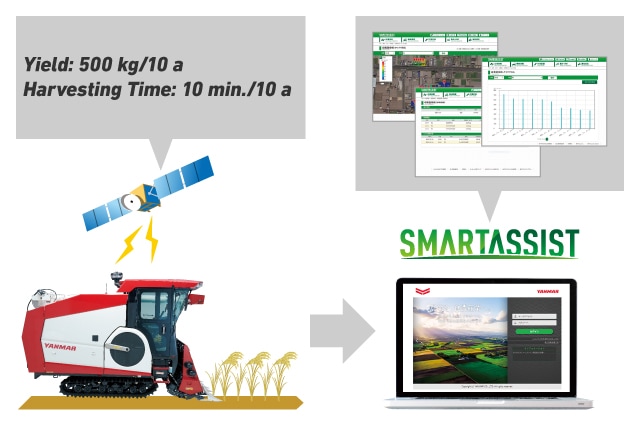

Smart Combine Harvester

Data, including that for yield, is measured during harvesting

By linking with SMARTASSIST, this year’s field harvest information can be used for next year’s cultivation planning and management !

Yield and work hours for fields registered with the SMARTASSIST are recorded and stored on a client-dedicated website.

The information can be easily modified and registered later according to the machine’s operation path.

Harvest information for each field can be aggregated and managed on a computer for use in next year’s cultivation planning and management.

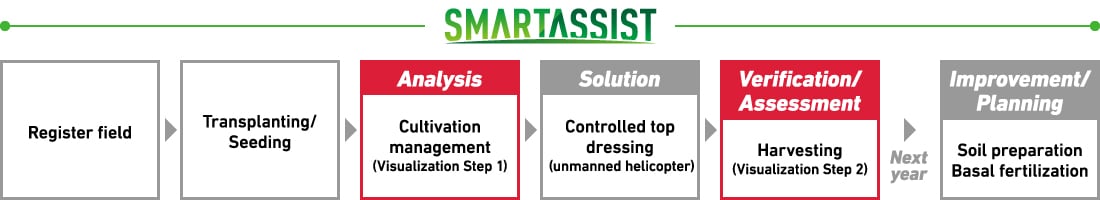

Practice more precise agriculture by combining Remote Sensing with Smart Combine Harvester

Analyzing field growth variation using growth maps obtained via remote sensing enables the use of controlled fertilization as a solution in minimizing such variations.

The yield map data obtained via the Smart Combine Harvester enables the effectiveness of controlled fertilization to be verified, after which it can be applied in soil preparation and fertilization plans for the following year.

Visualization Example 1. Remote Sensing

The whole field is captured with aerial photography using a specialized camera and then turned into a map used to visualize growth conditions for the whole field.

Visualization Example 2. Smart Combine Harvester

Data, including that for each field’s yield, is measured simultaneously during harvesting. It is then managed on the SMARTASSIST website.