Reduces fuel consumption by reducing the maximum engine speed by approximately 10%.

Efficiency

A ViO series top-class performance machine equipped with boom swing.

New hydraulic system ViPPS2i reduces engine load and fuel consumption while making the machine highly efficient.

The true Zero Tail Swing of this 8 t class excavator lets the driver operate the machinery without worrying about accidental collision of its rear end with the nearby objects, even when working in confined spaces.

Equipped with new hydraulic system (ViPPS2i) [Industry first in 8 t class]

(2-pump independent load-sensing system).

Hydraulic fluid flow is controlled according to load, mitigating the load placed on the engine

- ※Based on measurement methods used by Yanmar.

Realizing high efficiency and low fuel consumption

Fuel efficiency per Liter and fuel consumption in comparison to conventional models

An engine is powerful and good for people and environment.

- ※Picture of engine shown for illustration purpose only.

DIESEL PARTICULATE FILTER (DPF)*1

collect PM*(SOOT)

The minuscule amount of PM in the emissions gas is captured by the Diesel Particulate Filter (DPF), preventing its escape into the atmosphere and resulting in unparalleled environmental performance.

Cooled-EGR

Reduced Nox emissions by Exhaust Gas Recirculation

An Exhaust Gas Recirculation (EGR) system partially cools the exhaust gas and mixes it with suction air and circulates it within the cylinder. This process lowers the burning temperature inside the cylinder and decreases nitric oxide (NOX). The EGR valve controls the circulating amount of EGR depending on the density of the intake oxygen which reacts to the suction temperature and altitude. It allows a stable combustion control of fuel in every working conditions.

COMMON RAIL SYSTEM

Control fuel injection with a electric control

The Tier 4 engine uses a fully electronically controlled common rail and fuel injection system. At ignition, the system instantaneously collects and analyzes information such as the outside temperature and altitude (the oxygen concentration in the atmosphere), engine load conditions and DPF temperature for precise control of the fuel injection timing, fuel quantity and number of injection times for combustion control at millisecond intervals, in turn reducing the PM and NOX emissions.

4 Direct fuel injection system

Achieve low emission with high burning efficiency

In 1980, YANMAR was one of the first companies to implement direct injection combustion into its small diesel engines. Since then, YANMAR has used its in-house FIE parts manufacturing process to further develop its unique direct injection combustion technology that boasts low emissions, increased fuel economy and high power output. Tier 4 takes this technology to its limit in pursuit of optimal fuel injection for minimal particulate matter (PM) in the exhaust gas.

A much cleaner gas emission

A comparison between the non-road 2006 standard to 2014 standards of machines with engine output more than 19kW, less than 37kW

- ※1Diesel Particulate Filter (DPF) refers to the removal of particulate matter contained in exhaust emissions.

- ※2Soot and other particulate matter

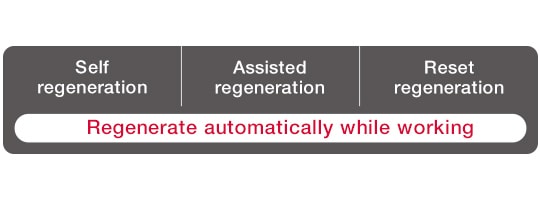

- ※3Manual regeneration may also be required according to on-site and usage conditions.

Use YANMAR genuine specialized oil for common rail engines equipped with a YANMAR DPF.

Three unique, automated regeneration technologies inhibit the development of soot.

- ※A manual regeneration may be necessary depending on work conditions.

Eco-mode function

Auto deceleration

If the operation lever stays in neutral for more than 4 seconds, the engine speed will automatically change to low idle.

The engine speed will automatically revert to the original speed once the operation lever is moved.