Energy - News Release

YANMAR CLEAN ENERGY SITE Established for Verification of Next-Generation Energy Equipment Towards a Decarbonized Society

August 31, 2023

Yanmar Holdings Co., Ltd.

Okayama, Japan (August 31, 2023) –Yanmar Energy Systems Co., Ltd. (Yanmar ES), a subsidiary of Yanmar Holdings, is set to inaugurate the YANMAR CLEAN ENERGY SITE on September 1, 2023, within Yanmar ES's Okayama Testing Center, establishing a verification facility for next-generation energy equipment aimed at achieving decarbonization.

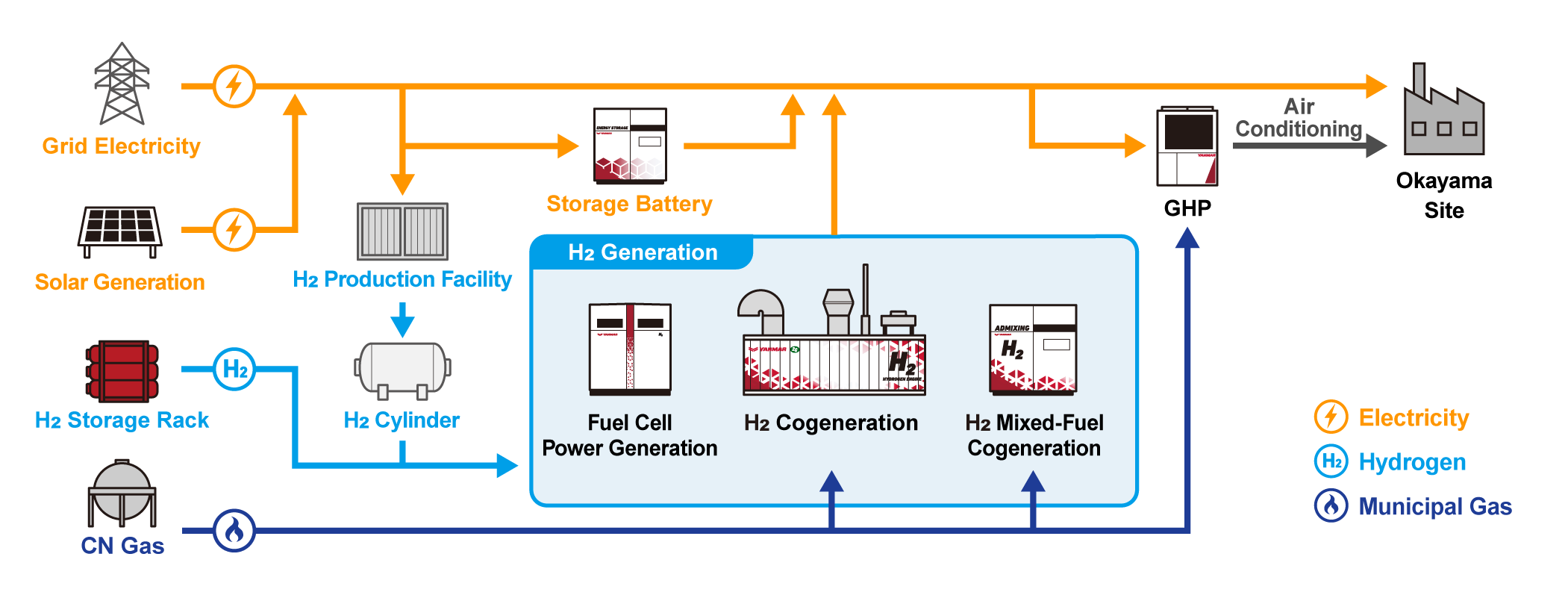

Under the banner of YANMAR GREEN CHALLENGE 2050, the Yanmar Group is committed to developing environmentally considerate solutions, including renewable energy (RE) and hydrogen, not only for their own operations but also to assist customers in realizing decarbonization. This initiative has led to the establishment of the YANMAR CLEAN ENERGY SITE, situated in the Okayama Testing Center on the premises of Yanmar Energy System Manufacturing Co., Ltd., which manufactures gas heat pump air conditioners (GHP) and micro cogeneration systems (CHP). The facility will carry out endurance testing, technical development, and verification tests of clean energy equipment such as hydrogen power generation systems and storage batteries, as well as optimizing their combined operation.

Looking ahead, the aim is to expertly combine existing products with evolving clean energy equipment, offering customized solutions under the Carbon Neutral Package to meet customer needs. Furthermore, the integration of clean energy equipment into the company's own factories will work towards achieving carbon neutrality across the entire production process.

Facility Overview

The facility, known as the YANMAR CLEAN ENERGY SITE, is designed to achieve the following three objectives by installing clean energy equipment centered around hydrogen power generation systems and conducting research and development.

- Verification: Swiftly support customers' efforts towards carbon neutrality by conducting development and verification tests related to carbon neutrality.

- Awareness: Raise awareness of Yanmar ES's commitment to carbon neutrality.

- Dialogue: Create a platform for dialogue with customers about their thoughts and challenges related to carbon neutrality, fostering collaborative solutions.

Opening Date: Friday September 1, 2023 Facility Name: YANMAR CLEAN ENERGY SITE Location: Yanmar Energy System Manufacturing Co., Ltd. premises, Okayama Prefecture Site Area: Approximately 1,000 square meters (including visitor unit house)

Key Equipment

1) Hydrogen Power Generation System

① Hydrogen Fuel Cell Power Generation System (under in-house development) The system offers a quiet, weather-resistant, emissions-free, and remarkably efficient power supply. It allows for the connection of multiple units to create customized systems aligned with desired power capacities.

② Hydrogen-Mixed Combustion Engine Micro Cogeneration System (under in-house development) Based on the established micro cogeneration system CP35D2 designed for municipal gas, this system enables operation with a blend of hydrogen fuel in city gas. Like the gas version, multiple units can be connected to propose systems tailored to required power levels.

③ Hydrogen Fuel Engine Cogeneration System by 2G Energy AG (Germany) With the ability to regulate output to match demand, this system offers both thermal and electrical supply utilizing hydrogen fuel, making it suitable for extensive projects. Benefiting from Yanmar's advanced maintenance technology, comprehensive support is provided even post-installation. The setup involves two units: one for exclusive hydrogen combustion and the other for a blend of city gas and hydrogen combustion.

2) Energy Storage System (Battery) (Under In-House Development)

This system stores surplus electricity generated from sources like solar and hydrogen power, contributing to the efficient and stable operation of energy.

3) Hydrogen Production Facility

Utilizing Italy's Enapter-manufactured hydrogen production system, green hydrogen is generated from renewable sources like solar power. This, along with solar energy and Yanmar's proprietary energy storage system (battery), enables streamlined management of green power distribution and the provision of power based on demand, effectively promoting the utilization of renewable energy.

4) Energy Management System (Y-EMS)

Not limited to Yanmar products, this system controls various energy devices based on weather and energy supply-demand conditions, supporting optimal device operation.

About YANMAR GREEN CHALLENGE 2050

The Yanmar Group is dedicated to a sustainable future through its YANMAR GREEN CHALLENGE 2050. By addressing three challenges—achieving zero GHG emissions in business operations, realizing environmentally friendly activities based on recycling resources, and contributing to customers' GHG negative emissions and resource circulation—the Group aims to embody its brand statement of A SUSTAINABLE FUTURE. For more information, visit https://www.yanmar.com/global/about/ygc/.

About Yanmar

With beginnings in Osaka, Japan, in 1912, Yanmar was the first ever to succeed in making a compact diesel engine of a practical size in 1933. A pioneer in diesel engine technology, Yanmar is a global innovator in a wide range of industrial equipment, from small and large engines, agricultural machinery and facilities, construction equipment, energy systems, marine, to machine tools, and components — Yanmar’s global business operations span seven domains. On land, at sea, and in the city, Yanmar provides advanced solutions to the challenges customers face, towards realizing A Sustainable Future. For more details, please visit the official website of Yanmar Holdings Co., Ltd.

Press Release Download

- Note: Information contained in the news release is valid at the time of publication and may differ from the most recently available information.

Inquiries

Corporate Communications, Yanmar

E-mail: newsroom@yanmar.com