Regular maintenance increases the life of the product

Daily inspections and regular maintenance are important to maintain product safety and performance.

Performing regular maintenance according to the product usage prevents breakdowns and serious accidents, and will reduce running costs.

It also brings out the best performance of the product and extends its life.

Maintenance parts for Industrial Engines

Here are some typical maintenance and replacement parts for industrial engines (actual parts may vary for the product you are using).

*Maintenance method differs depending on the product.

Please check your operation manual.

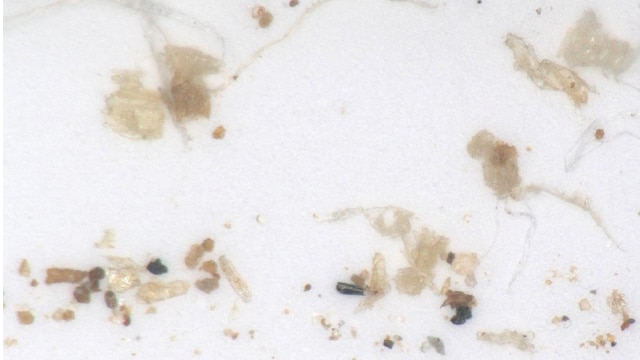

Lubrication oil filter

Before use

After use

The lubrication oil filter removes fine metal particles and carbon mixed in the engine lubricating oil.

When the filter becomes dirty, the engine will not work properly or may even cause a malfunction. Therefore, the filter needs to be replaced regularly.

Recommended replacement time: Every 500 hours

Fuel filter

Before use

After use

The fuel filter removes particles and deposits in diesel fuel.

When the fuel gets contaminated, foreign matter will stick to the valve. This will lead to a lower combustion efficiency and deterioration of engine performance.

YANMAR genuine filters have a high filtration ratio and are long-lasting, but they do require regular replacement.

Recommended replacement time: Every 500 hours

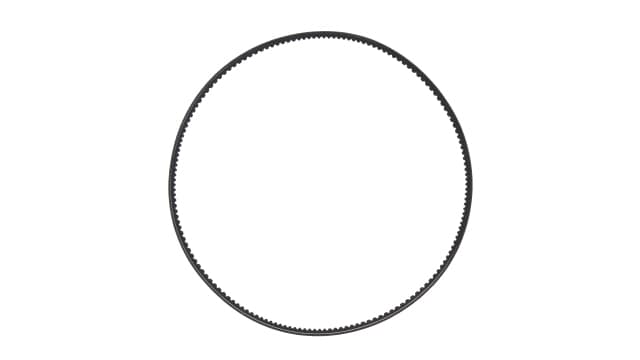

V-belt

Before use

The V-belt drives the cooling fan thereby cooling the engine.

If the tension of the V-belt loosens or if best the breaks, the engine will not be sufficiently cooled, causing overheating.

Recommended replacement time: Adjust tension every 250 hours.

Replace if necessary.

Filter element and Air cleaner

Before use (Left: Filter element, Right: Air cleaner)

The filter element and air cleaner keep airborne particles out of the engine.

The frequency of replacement will vary depending on the operating environment, but it is necessary to inspect and replace regularly.

Recommended replacement time: Every 500 hours

Examples of engine failures caused by insufficient maintenance - Industrial Engines

Performing regular maintenance according to the usage status prevents breakdowns and serious accidents and reduce running costs.

This is what may happen if you do not perform regular maintenance to your YANMAR product.

YANMAR recommends regular maintenance to prevent breakdowns and to ensure that the product can be used for a longer period of time.

We recommend to have regular inspections and maintenance carried out by professional service staff, so please contact your nearest dealer.

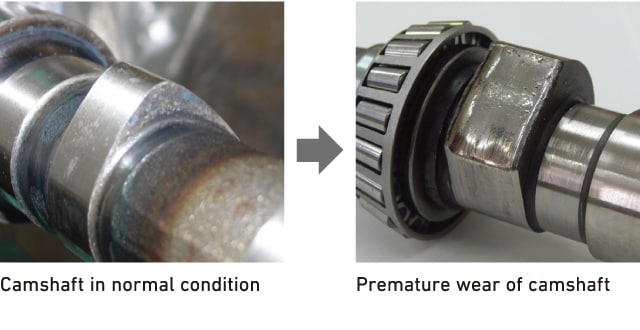

CASE 01. Prolonged use of engine oil and LO filters

CASE 02. Prolonged use of fuel filter

CASE 03. Insufficient lubrication

CASE 04. Insufficient maintenance of intake valve

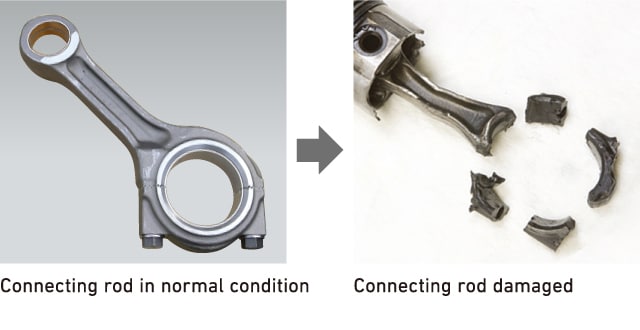

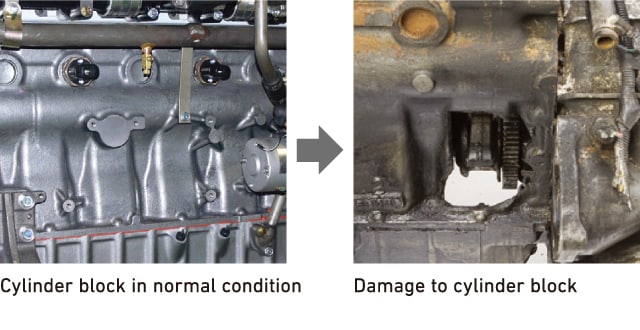

Engine trouble due to the improper use of oil

This happens when the engine runs dry of oil due to improper use of oil or not performing maintenance at the required interval.

In order to continue using your equipment with peace of mind, it is important to use the right oil and perform maintenance at the right time.

Piston

Camshaft

Connecting rod

Cylinder block

YANMAR's new method maintenance. Towards zero downtime

Performing maintenance tailored to the needs of the customer using ICT

YANMAR will attach sensors to the customer's machine, and analyze the operational load to the product what part of the equipment is most under load. This way, we can choose the optimal maintenance based on load.

We also set up a "Remote Support Center" to provide our customers comprehensive support.

We are working to realize advanced "preventive maintenance", and provide our customers with “no downtime” service. We also will provide management support by utilizing the equipment data we accumulate.

* Please contact the sales office in each region.

Agriculture

Agriculture

Recreational Marine

Recreational Marine

Recreational Boat

Recreational Boat

Premium Cruiser

Premium Cruiser

Marine Equipment

Marine Equipment

Marine Commercial

Marine Commercial

Propulsion Engines (High Speed)

Propulsion Engines (High Speed)

Propulsion Engines (Medium Speed)

Propulsion Engines (Medium Speed)

Auxiliary Engines

Auxiliary Engines

SCR System

SCR System

Dual Fuel Engine

Dual Fuel Engine

Two-stage Turbocharging System

Two-stage Turbocharging System

Electric Propulsion System

Electric Propulsion System

Energy Systems

Energy Systems

Compact Equipment

Compact Equipment

Industrial Engine

Industrial Engine

Power Generation

Power Generation

Compact Power Products

Compact Power Products