Founded in 1912, YANMAR succeeded to develop the world's first commercially viable compact diesel engine in 1933. Since then, continuing to embody our company founder's philosophies of “Wasting not one drop of fuel” and “Releasing people from the burden of heavy labor”, we have been a pioneer in the production of high-performance industrial engines.

In 2012, we became the world’s first engine manufacturer to clear CARB (California Air Resources Board) Tier 4 (19-56kW class) emission regulations, and in 2013 we were also first to obtain certification under the Swiss Ordinance on Air Pollution Control (18-37kW class). Carrying out advanced research based on engineering skills fostered over years of experience in engine development, YANMAR will continue to pursue cutting-edge technology capable of clearing environmental regulations in all countries.

At our Biwa Factory in Shiga Prefecture, we operate a highly efficient automatized production system which enables multiproduct-mixed production of over 2,000 engine models. This is our industrial engine “Mother Factory”, delivering high-quality engines for a wide range of industrial machinery both in Japan and overseas.

Via our global network, we can respond to the varying customer needs and regulatory requirements unique to each part of the world, enabling us to deliver engines which are tailored to our customer’s demands.

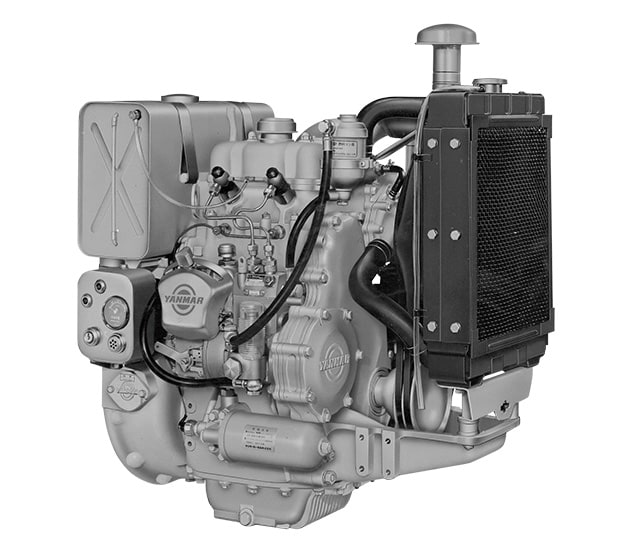

Industrial Engine

Machinery powered by YANMAR engines

Sales and production sites

Production sites

YANMAR POWER TECHNOLOGY CO., LTD. Biwa Factory / Ibuki Factory

YANMAR POWER TECHNOLOGY CO., LTD. Biwa Factory / Ibuki Factory

- Vertical Water-cooled Diesel Engines

- Vertical Water-cooled Gas Engines

YANMAR ENGINE (SHANDONG) CO., LTD.

YANMAR ENGINE (SHANDONG) CO., LTD.

- Vertical Water-cooled Diesel Engines

YANMAR ENGINE MANUFACTURING INDIA PVT. LTD

YANMAR ENGINE MANUFACTURING INDIA PVT. LTD

- Vertical Water-cooled Diesel Engines

YANMAR S.P. CO., LTD.

YANMAR S.P. CO., LTD.

- Horizontal Water-cooled Diesel Engines

PT. YANMAR DIESEL INDONESIA

PT. YANMAR DIESEL INDONESIA

- Horizontal Water-cooled Diesel Engines

- Machining of Engine Parts

PT. YANMAR INDONESIA

PT. YANMAR INDONESIA

- Casting

- Machining of Engine Parts

YANMAR ITALY S.p.A.

YANMAR ITALY S.p.A.

- Air-cooled Diesel Engines

Sales sites

YANMAR POWER TECHNOLOGY CO., LTD.

YANMAR POWER TECHNOLOGY CO., LTD.

YANMAR ENGINE (SHANGHAI) CO., LTD.

YANMAR ENGINE (SHANGHAI) CO., LTD.

YANMAR ASIA (SINGAPORE) CORPORATION PTE. LTD.

YANMAR ASIA (SINGAPORE) CORPORATION PTE. LTD.

YANMAR ENGINE MANUFACTURING INDIA PVT. LTD

YANMAR ENGINE MANUFACTURING INDIA PVT. LTD

Head Office

YANMAR EUROPE B.V.

YANMAR EUROPE B.V.

YANMAR AMERICA CORPORATION

YANMAR AMERICA CORPORATION

YANMAR SOUTH AMERICA INDUSTRIA DE MAQUINAS LTDA.

YANMAR SOUTH AMERICA INDUSTRIA DE MAQUINAS LTDA.

Production sites (Shiga pref. Japan)

Biwa Factory

Biwa Factory

- Vertical Water-cooled Diesel Engines

- Vertical Water-cooled Gas Engines

Ibuki Factory

Ibuki Factory

- Vertical Water-cooled Diesel Engines

- Transmissions

Kinomoto Factory

Kinomoto Factory

- Fuel injection components

- Machining of engine parts

Omori Factory

Omori Factory

- Parts for Fuel Injection Components

YANMAR CASTING TECHNOLOGY CO., LTD.

YANMAR CASTING TECHNOLOGY CO., LTD.

- Casting

- Machining of Engine Parts

Research & Development Center

Research & Development Center

Milestones

1912 - 1945

| 1912 |

Magokichi Yamaoka founded YAMAOKA HATSUDOKI KOSAKUSHO in Osaka, conducting repairs and sales of gas engines. |

|---|---|

| 1930 |

Launched a vertical 2-stroke 5 Hp diesel engine (the beginning of our compact diesel engine business). |

| 1933 |

Developed the HB Series, the world's first commercially viable compact diesel engine (5-6 Hp). |

| 1936 |

Established Kanzaki Factory and began production of S Series compact horizontal water-cooled diesel engines. |

| 1937 |

Adopted company motto - “To conserve fuel is to serve mankind”. |

| 1942 |

Established Nagahama Factory in Shiga Prefecture. |

1946 - 1959

| 1949 |

Established Nagahara Factory in Shiga Prefecture, starting production of fuel injection parts for compact diesel engine. |

|---|---|

| 1952 |

Launched the K1, the world's most compact horizontal water-cooled diesel engines (1.5-2Hp). |

| 1956 |

Established technical research center in Oyodo, Osaka. |

| 1959 |

Launched world's first ultra-compact air-cooled diesel engine model (3.5 Hp A2 model, and 4.5 Hp A3 model). |

1960 - 1969

| 1960 |

Established Omori Factory in Shiga Prefecture, starting production of fuel injection pumps. |

|---|---|

| 1968 |

Started production of 2W90, YANMAR’s first vertical water-cooled diesel engine (20 Hp). |

| 1968 |

Became first diesel engine manufacturer to be awarded the Deming Prize. |

1970 - 1979

| 1970 |

Established KOGA PRECISION CASTING CO., LTD in Shiga Prefecture (now YANMAR CASTING TECHNOLOGY CO., LTD), and started production of precision casting parts for industrial engines. |

|---|---|

| 1970 |

Started production of 2TR22 high-speed 2-cylinder vertical water-cooled diesel engine (22 Hp) for tractors. |

| 1971 |

Started production of G25 air-cooled gasoline engine (2.5 Hp). |

| 1972 |

Established P.T. YANMAR DIESEL INDONESIA (YADIN) in Jakarta and started production of horizontal water-cooled diesel engines in 1973. |

| 1973 |

Established assembly line at Nagahama Factory for vertical water-cooled diesel engines. |

| 1976 |

Started production using unique new “YANMAR Production Method” at Nagahama Factory. |

| 1976 |

Started production of T Series multi-cylinder vertical water-cooled diesel engines (12.5-31 Hp). |

| 1977 |

Established research and development center in Kyoto. |

| 1978 |

Established YANMAR THAILAND CO., LTD. in Bangkok and started production of horizontal water-cooled diesel engines. |

| 1979 |

Started production of high-speed 3-cylinder vertical water-cooled diesel engine, TH Series (12.5-42 Hp). |

1980 - 1989

| 1980 |

Launched YANMAR’s first vertical water-cooled “direct injection(DI)” diesel engine (3T95). |

|---|---|

| 1981 |

Celebrated the production of 5 millionth horizontal water-cooled diesel engine. |

| 1983 |

Launched TN Series direct injection vertical water-cooled diesel engines (11-100 Hp). |

| 1983 |

Started production of L Series, the world's most compact and lightest air-cooled diesel engines (3.5-9 Hp). |

| 1986 |

Started production of 3GP66, YANMAR’s first gas engine (11.5 Hp). |

| 1989 |

Started production of 4TN84-RAC, YANMAR’s first electronically governed diesel engine. |

1990 - 1999

| 1993 |

Launched TNE Series industrial vertical water-cooled diesel engines (8.6-84.2 kW). |

|---|---|

| 1995 |

Established Biwa Factory in Shiga Prefecture, for production of industrial vertical water-cooled engines. |

| 1995 |

Established YANMAR CAGIVA S.p.A. as a joint venture with Italian company Cagiva and started production of air-cooled diesel engine. |

2000 - 2009

| 2000 |

Established Research and Development Center in Maibara, Shiga Prefecture. |

|---|---|

| 2002 |

Launched TNV Series vertical water-cooled diesel engines. |

| 2003 |

Renamed YANMAR CAGIVA S.p.A as YANMAR ITALY S.p.A (YI). |

| 2003 |

Established SHANDONG SHIFENG YANMAR ENGINE CO., LTD in China, as a joint venture with Chinese agricultural machinery manufacturer SHANDONG SHIFENG GROUP. |

| 2007 |

Renamed SHANDONG SHIFENG YANMAR ENGINE CO., LTD as YANMAR ENGINE (SHANDONG) CO., LTD. |

2010 -

| 2012 |

Started production of TNV common rail series engines. |

|---|---|

| 2012 |

4TNV88C common rail diesel engine became the world's first engine to get Tier 4 certification by the CARB (California Air Resources Board) in the 19-56 kW class. |

| 2013 |

TNV common rail series engines became the world's first engine models to get the certification under the Swiss Ordinance on Air Pollution Control (18-37 kW class). |

| 2013 |

Started casting of engine components at PT. YANMAR INDONESIA. |

| 2016 |

Started production of vertical water-cooled diesel engines at Ibuki Factory. |

| 2018 |

Developed two new models of 155 kW high-output industrial diesel engines (4TN101 and 4TN107). |

| 2018 |

Established YANMAR ENGINE MANUFACTURING INDIA PVT. LTD. for production of vertical water-cooled diesel engines. |

| 2019 |

Achieved 10 millionth vertical water-cooled engine. |

| 2019 |

Developed two new models of industrial gas engines (4TN88G and 4TN98G) |

| 2020 |

Established YANMAR POWER TECHNOLOGY CO., LTD. |

Marine Commercial

Marine Commercial

Recreational Marine

Recreational Marine

Compact Equipment

Compact Equipment

Industrial Engine

Industrial Engine

Compact Power Products

Compact Power Products

Genuine Parts

Genuine Parts Energy Systems

Energy Systems

Power Generation

Power Generation