Development was started based on consultations from customers regarding their concerns.

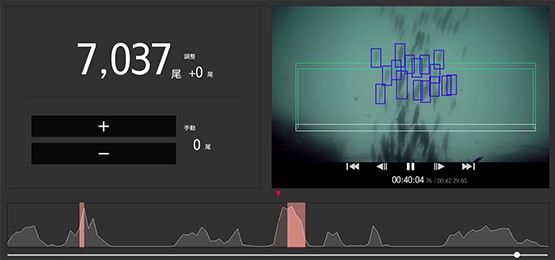

In fish farming, it is essential to know the number of fish inside each net in order to control production volume and the amount of feed used, and also to submit reports and other materials to the Fisheries Agency. In particular for farming of tuna, where the price per fish is high, more accurate counting also results in more efficient operations.

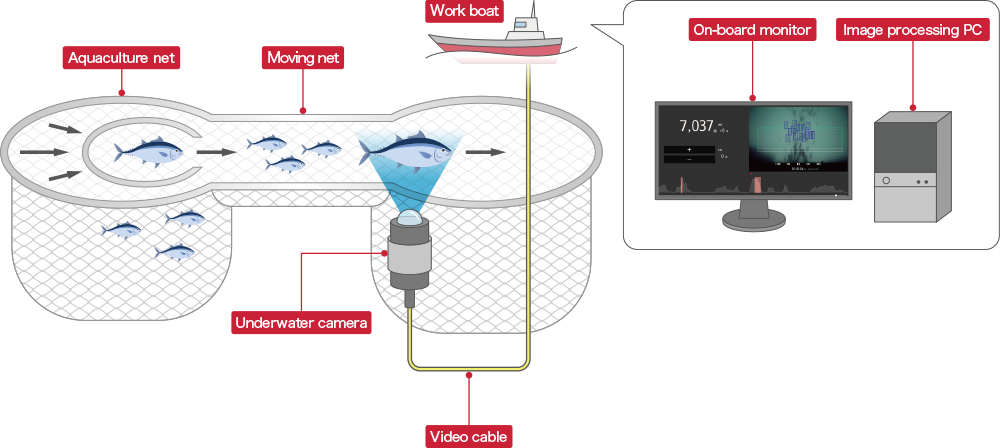

The reason for the start of the automated fish counting system project was the concern raised by customers who were engaged in tuna farming over the difficulty in counting the number of fish for management. At that time, two main methods were used to count fish at most fish farms. The first was installing a camera in the net, or having a diver carry a camera, to capture images, and then visually counting each individual fish. The second was having a diver enter the net and count the number of dead fish, and subtracting that number from the previous total for management. Both methods place a large burden on the person performing the work, and the level of accuracy varies.