Engines that consider global environment and operate with high economic efficiency

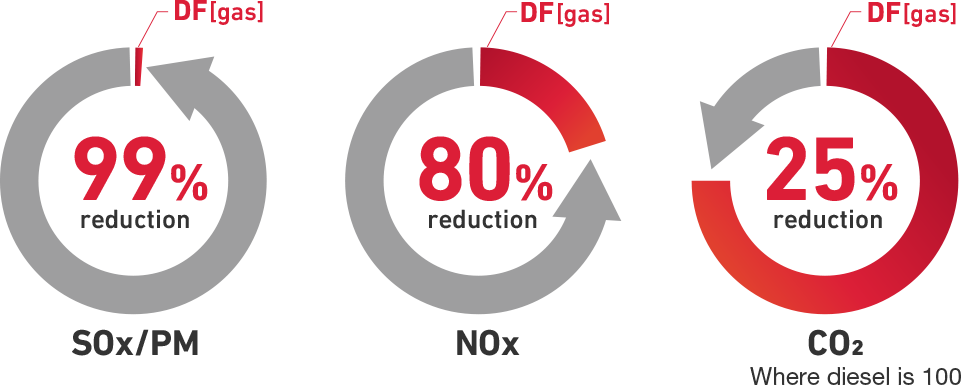

Large vessels operating in the seas around the world are equipped with engines with high power. An issue confronting our world today is the air pollutants from the emission of those large engines. In recent years, the use of natural gas has attracted attention. Liquefied natural gas (LNG) is environmentally friendly and can reduce greenhouse gases. Therefore, Yanmar has begun developing the dual-fuel engine that can flexibly use both LNG and diesel fuel to take advantage of eco-friendliness and wider availability. We set the goal high to develop a new engine complying with The International Marine Organization (IMO) Tier 3 NOX (IMO3) and SOX regulations for all sea areas based on a reliable model that can pursue improvements in the life cycle value (LCV) for customers.

Effective since January 1, 2016, the 3rd tier regulation (IMO3) is that IMO requires on the standard of NOX emission control. IMO3 to regulate 80% lower emissions than the primary regulation, is applied within a designated sea area called NOX Emission Control Area (N-ECA). The US and Canadian coasts, the U.S. Caribbean, the North Sea and the Baltic Sea have already been regulated for SOX, while the U.S. and Canadian coasts have already been regulated for NOX. The North Sea and the Baltic Sea will be subject to regulation from January 1, 2021.

Agriculture Equipment

Agriculture Equipment Compact Equipment

Compact Equipment Utility Task Vehicles

Utility Task Vehicles Industrial Engines

Industrial Engines Recreational Marine

Recreational Marine Marine Commercial

Marine Commercial Propulsion Engines (High Speed)

Propulsion Engines (High Speed) Propulsion Engines (Medium Speed)

Propulsion Engines (Medium Speed) Auxiliary Engines

Auxiliary Engines SCR System

SCR System Dual Fuel Engine

Dual Fuel Engine Two-stage Turbocharging System

Two-stage Turbocharging System Electric Propulsion System

Electric Propulsion System Net Cleaning Robot

Net Cleaning Robot Energy Systems

Energy Systems Compact Power Products

Compact Power Products YANMAR RePower

YANMAR RePower Genuine Parts

Genuine Parts