Development Division

YANMAR ENERGY SYSTEM CO., LTD.

YANMAR Technical Review

Development of High-Efficiency GHP: Toward an Energy-Saving Lifestyle for Our Customers and a Society Where They Can Work and Live with Peace of Mind

Abstract

Improving energy conversion efficiency is an important issue if society is to become more environmentally friendly.

Yanmar Energy System Co., Ltd. has developed an environment-friendly gas heat pump (GHP) air conditioner that improves air conditioning efficiency by 15% and uses 36% less refrigerant than previous models.

The new model is also lighter and has a 20% reduced installation footprint, making it easier for customers to undertake refurbishments, including those involving equipment replacement. The GHP is supported by a remote monitoring system that can also perform software updates. Through these features, Yanmar is helping to build a society in which customers can have peace of mind as they live and work in an energy-efficient manner.

1.Introduction

Gas-engine-powered gas heat pump (GHP) air conditioners are being promoted by the government as tool for reducing peak electricity demand*1. That is, along with reducing both upfront and running costs for customers (in the former case by not requiring an electrical refit), they also serve a public benefit.

On top of these considerations, the need to prevent global warming caused by the emission of greenhouse gases has, over recent years, seen a greater importance being placed on energy efficiency, decarbonization, and minimizing the release of fluorocarbons.

Through the development of a new L1 series of GHPs (see Fig. 1) featuring remote support combined with lighter weight and smaller size achieved by improving air conditioning efficiency and reducing the amount of refrigerant, Yanmar Energy System is helping to build a society where people can live with peace of mind.

- *1Government guidelines for business on measures for smoothing peaks in electricity demand at factories and other facilities (Notice No. 271 of the Ministry of Economy, Trade and Industry, December 27, 2013)

2.Improved Air Conditioning Efficiency

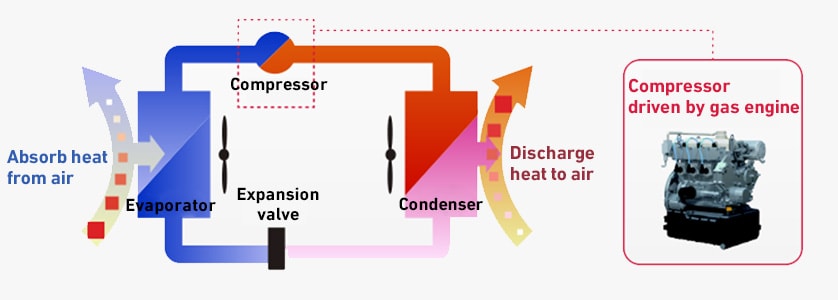

2.1.GHP Refrigerant Circuit

For heat pump air conditioners, which consist of a refrigerant circuit with a compressor and a heat exchanger (evaporator and condenser), heat exchange efficiency is one of the main factors influencing overall air conditioning efficiency. As shown in Fig. 2, improving the efficiency with which heat is absorbed and released results in lower gas consumption because it reduces the load on the compressor and gas engine.

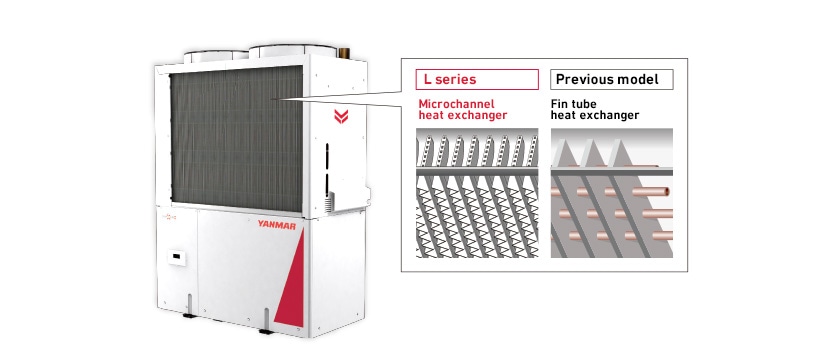

2.2.Use of Microchannel Heat Exchanger

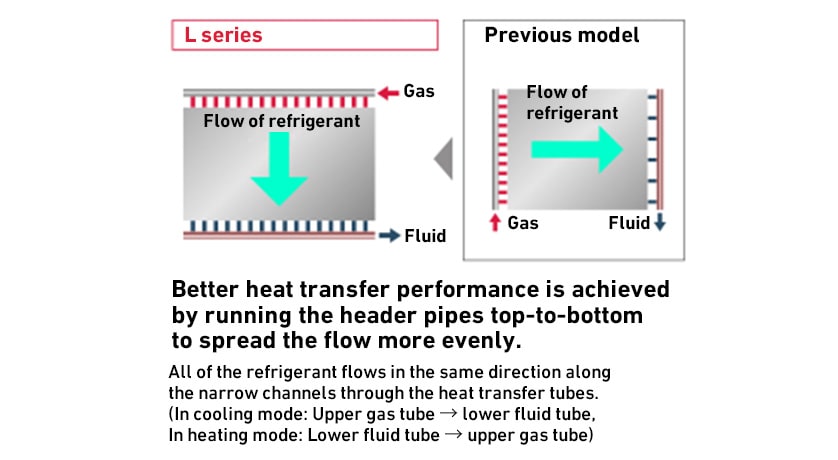

In the new L1 series GHP, the fin tube heat exchanger used previously has been completely replaced with a microchannel heat exchanger (MC heat exchanger). The heat transfer tubes in this new MC heat exchanger are formed from several hundred thin pieces of aluminum, each of which has several dozen capillaries running through it. These are stacked and soldered together with aluminum fins. This configuration improves heat transfer by increasing the exposed surface area for both refrigerant and air (see Fig. 3). A more even flow of refrigerant has been achieved by having the refrigerant flow through the heat transfer tubes vertically rather than horizontally as before. As the refrigerant flows vertically downward in cooling mode, it is not fighting gravity as it condenses (see Fig. 4).

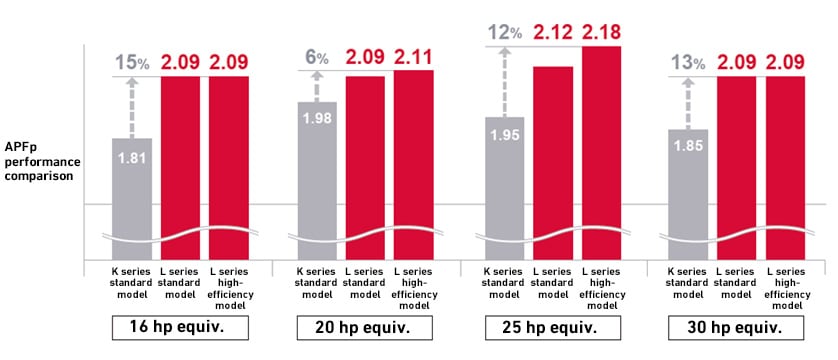

These enhancements succeeded in improving heat transfer performance and in delivering a significant increase in air conditioning efficiency (up to 15%) over the previous K series models when measured on an APFp*2 basis.

(Standard model: equipped with lean-burn engine,

High-efficiency model: equipped with stoichiometric lean-burn engine)

- *2Primary annual performance factor, as defined in JIS B 8627:2015

The total cooling load and total heating load divided by the energy consumed over the time period.

3.Smaller Size and Lighter Weight

3.1.Increased Diameter of Propeller Fans

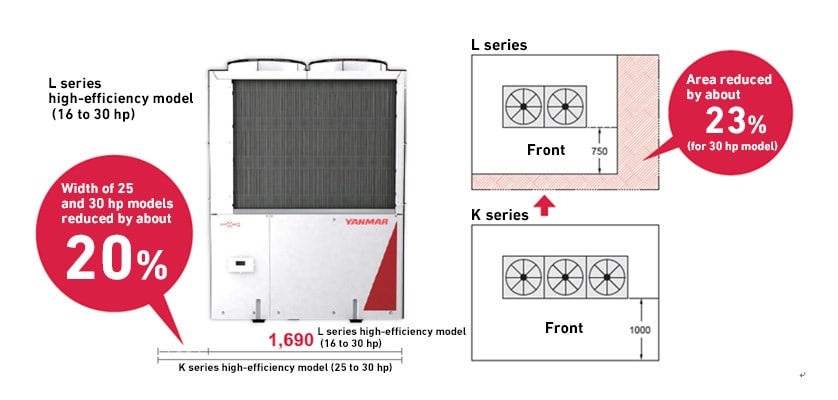

Whereas the previous K1 series was available in two different housing sizes for GHPs of 20 hp or less and 25 hp or more, respectively, in the L1 series the width of these latter models has been reduced to enable the same external dimensions for all models from 16 hp to 30 hp. As shown in Fig. 6, the installation footprint of the higher capacity (25 hp or more) GHPs has been reduced by approximately 20% compared to the previous series. Ease of installation has also been enhanced by reducing the maintenance space requirement.

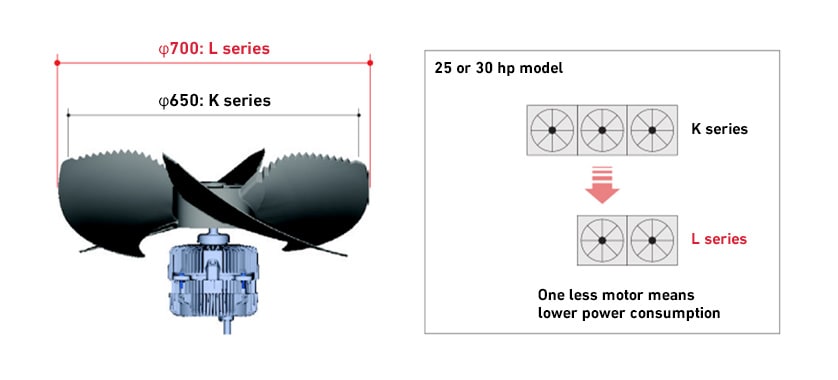

As shown in Fig. 7, the propeller fan diameter has been increased to facilitate these size reductions, allowing twin fans to be used on the outdoor units of the 25 hp and 30 hp models in place of the three fans used previously. The elimination of an electric motor reduces power consumption and makes the unit lighter while reducing the housing size.

3.2.Additional Heat Exchanger on Side of GHP

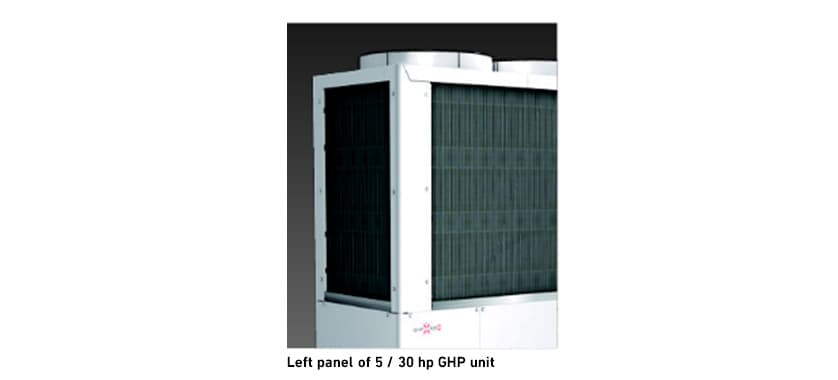

To provide sufficient heat exchange area (heat exchange capacity), an additional heat exchanger has been placed on the side of the unit, as shown in Fig. 8. The previous model had heat exchangers on the front and rear only.

Along with smaller size and lighter weight, this provides for greater parts uniformity and consistency of exterior design, which previously differed for different horsepower ratings.

4.Software Updating over Remote Monitoring System

Rather than just new hardware technology, functional upgrades in recent years have increasingly been made by means of software. As a product intended to provide reliable service to customers over a long period of time, there are an increasing number of instances where improvements in the durability and functionality of GHPs need to be made by upgrading software, including for units that are already installed.

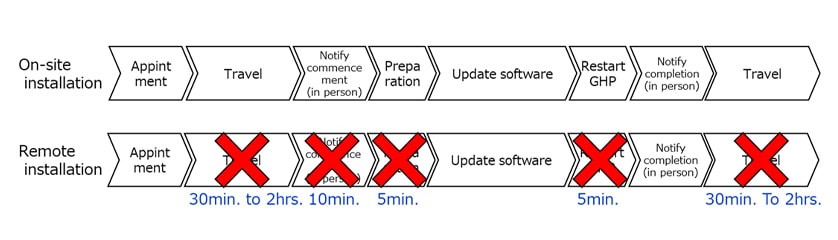

Updating the software at an existing installation requires a lot of work by the service person, including not only the task itself, but also travel time, preliminary preparations, and cleaning up afterwards. Along with the acceptance and inspection arrangements, this also causes the customer the inconvenience of having the unit out of service during the upgrade.

For the L1 series, the remote monitoring system has been upgraded to enable software updates to be installed from an office or other remote location. As shown in Fig. 9, this eliminates several hours of work per site, equating to the time that would previously have been spent on travel, preparation, and restarting the system afterwards.

5.Conclusions

The L1 series of GHPs described in this article are environmentally friendly GHP air conditioners that feature significantly higher efficiency of up to 15% and 36% less refrigerant than the previous K series. By developing technology for energy-efficient products and promoting their wider adoption, thereby reducing power consumption and CO2 emissions, Yanmar is helping to build a society in which customers have peace of mind as they live and work in an energy-efficient manner.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Innovation & Technology Division, Technology Strategy Division.

Author