Development Division

YANMAR MARINE INTERNATIONAL ASIA CO., LTD.

YANMAR Technical Review

Electronic Control Technology for Easier Vessel Operation: VC20 Electronic Vessel Control System

Abstract

Launched in 2011, the VC10 was the first electronic vessel control system to be developed by Yanmar. The system has since been used to control various different types of marine engines, transmissions, and boats all over the world, with ongoing functional enhancements that have included a joystick control system and GPS-based position keeping system.

The new VC20 maintains the same high level of reliability and functionality as its predecessor, also featuring enhanced ease-of-use and visual design with the control head and switch panel having been upgraded in response to customer demand. The system specifications have been further enhanced by the adoption of a new electronic control unit (ECU) with enhanced memory and the use of Controller Area Network (CAN) communications to simplify the electrical architecture and make installation easier.

This article describes the new VC20 electronic vessel control system.

1.Introduction

As a provider of total marine solutions, Yanmar’s products have extended beyond marine engines and propulsion units, also including the VC10 electronic vessel control system launched in 2011 with the objective of providing customers with comfort, convenience, safety, and peace of mind. The VC10 is compatible with electronically controlled engines from 40 to 1,000 hp and can adapt flexibly to the needs of a wide variety of systems for vessel operation from all over the world in both pleasure boat and commercial applications. Yanmar has progressively enhanced the competitiveness of the VC10 since it first went on sale, striving to meet the needs of the market through the ongoing development of new features, including joystick control and position keeping.

Yanmar subsequently went on to launch the VC20 second-generation control system in 2019, featuring upgrades to the helm controls and system configuration to deliver even greater value to customers. This article presents an overview of the electronic vessel control systems developed by Yanmar and describes the technical features of the new VC20 system.

2.Overview of Yanmar Electronic Vessel Control Systems

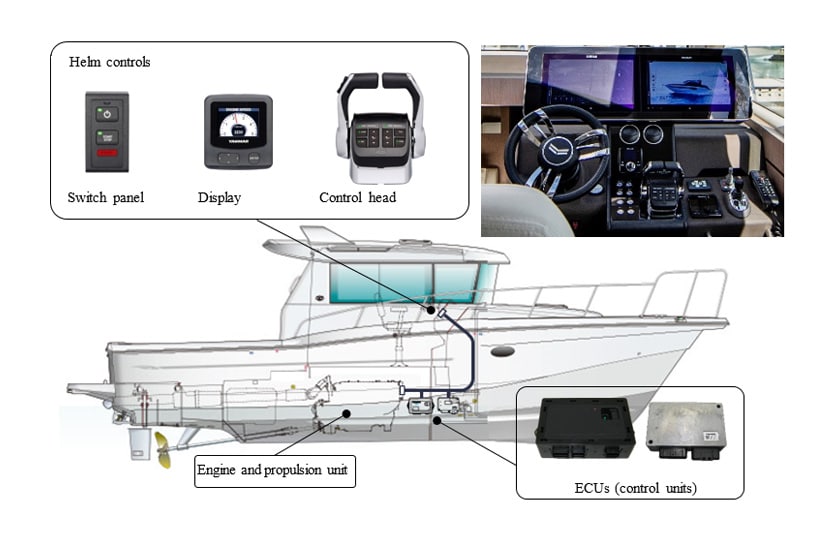

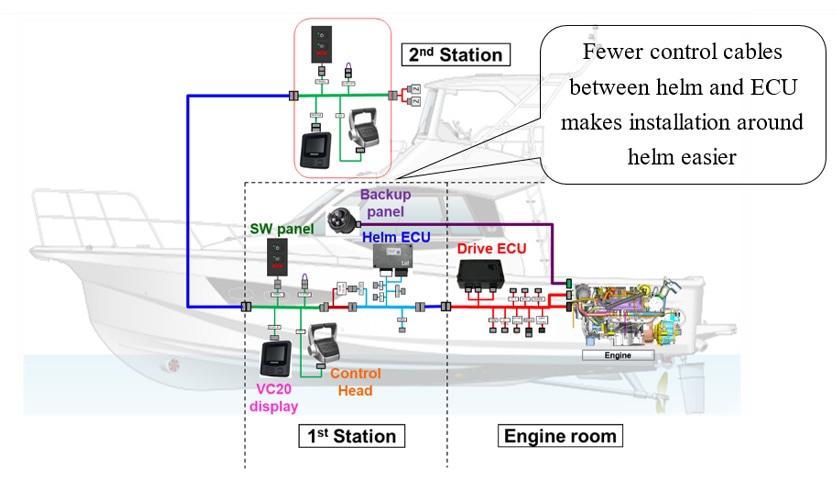

Yanmar’s electronic vessel control systems are made up of the helm controls (including the control head, switch panel, and displays) and a number of electronic control units (ECUs) (Fig. 1). The system works by sending control signals for the engine and transmission to the various ECUs in response to user operation of the throttle, shift lever, or switches on the helm, such as starting or stopping and increasing or decreasing power. The ECUs control the engine and propulsion unit in accordance with these signals.

The ECUs are linked by a Controller Area Network (CAN) based on the SAE J1939 standard, exchanging large amounts of complex information to implement not only basic vessel operation, but also a wide variety of other functions. Past examples have included providing users with convenient and useful functions for vessel operation such as synchronizing the speed of multiple engines, adjusting the feel of the throttle lever, running at low speed for trawling, or adjusting the trim angle of the stern drive. As the displays are likewise connected to the ECUs and CAN, along with displaying information about the engine and propulsion unit, they can also be used to provide a full range of functions for safety and peace of mind, including a password lock to prevent theft and displaying pop-up alarms when problems are detected.

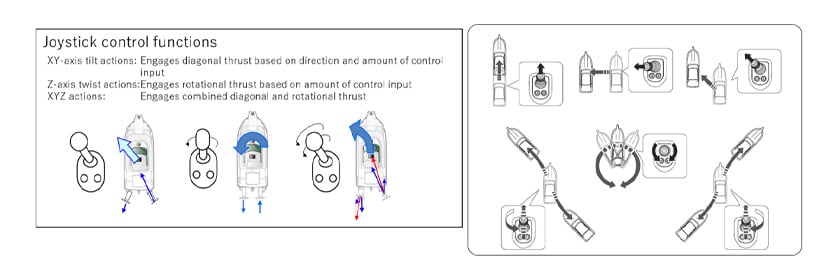

A joystick control system is also available as an option. Vessels can be turned around or maneuvered in any direction in response to the user tilting or twisting the joystick, which is achieved through precise control by the ECUs over the rudder angle and the speed of the multiple engines and propulsion units. The intuitive control provided by a joystick makes it easy for even beginners to complete the difficult task of maneuvering a vessel into or out of a berth like an experienced sailor (Fig. 2).

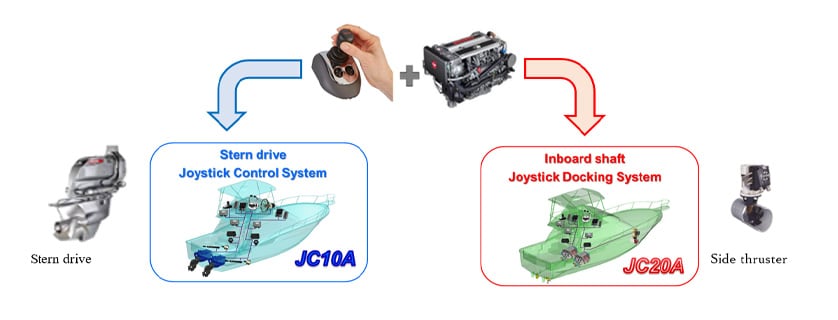

The joystick control system is available for both stern-drive (JC10A) and inboard shaft (JC20A) powerboats (Fig. 3).

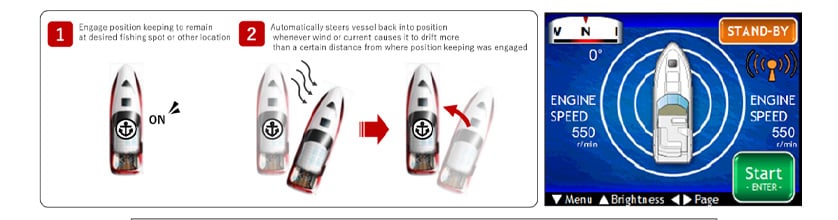

Another option is a position keeping function available with the JC10A joystick control system for stern-drive powerboats. This function uses an antenna mounted on the vessel to receive position information from a global navigation satellite system (GNSS) and works by having the ECU automatically control the longitudinal and rotational movement of the vessel so as to maintain a constant position and orientation. This prevents the vessel from drifting due to wind or current without having to put down an anchor (Fig. 4).

3.New VC20 Vessel Control System

3.1.System Configuration Provides Ease-of-Installation and Expansion Capabilities

In addition to the numerous functions provided by the previous VC10 system, the specifications of the VC20 were also upgraded to enhance product competitiveness and deliver greater added value. This section describes these enhancements.

1) Ease-of-installation and expansion capabilities achieved by connecting helm via CAN

The VC20 uses CAN communications throughout, including the connections between the helm and ECUs. This reduces the amount of control cabling needed to connect devices to the ECUs and makes installation around the helm much easier, an area that in the past required a lot of wiring (Fig. 5). Whereas the ECUs in the previous system took input directly from the helm controls, requiring a separate one for each helm, using CAN has eliminated this requirement and thereby reduced the number of ECUs needed.

Another consequence of using CAN to network the helm is that connected devices can be detected automatically by the display. This allows system installations to be completed more quickly and with less risk or error as the display screens can be used for device configuration.

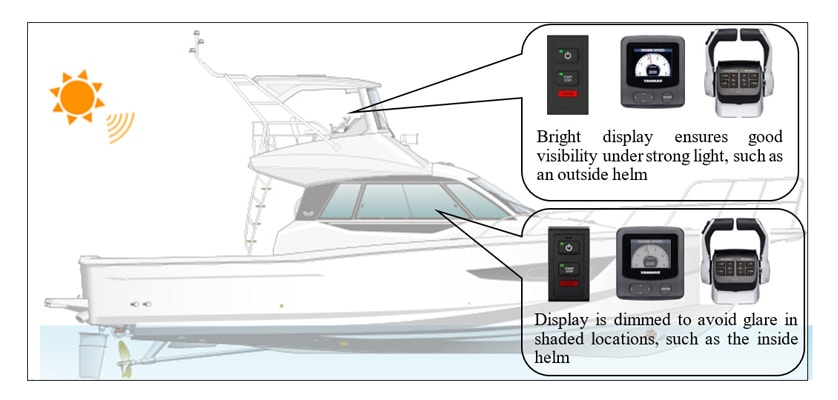

An auto-dimming function that utilizes CAN communications (Fig. 6) eliminates the need for the user to adjust helm LED brightness manually. Illumination sensors built into the switch panels measure the level of light around each helm and this information is linked via CAN communications to the display and control head for that helm to adjust the LED brightness automatically. Auto-dimming maintains good visibility for the helm controls at different locations (inside or outside) and in response to changes in the level of sunshine or other ambient light.

2) Additional functions made possible by higher ECU performance

The enhanced memory capacity and higher specifications of the ECUs used in the VC20 have facilitated the addition of new functions. One example is how the control software for the JC10A joystick control system described above becomes larger and more complex when its scope is extended to support boats fitted with three separate engines and propulsion units. By upgrading the specifications of the ECU, however, precise control operation could be implemented to provide optimal joystick control for such triple-engine, triple-axis powerboats.

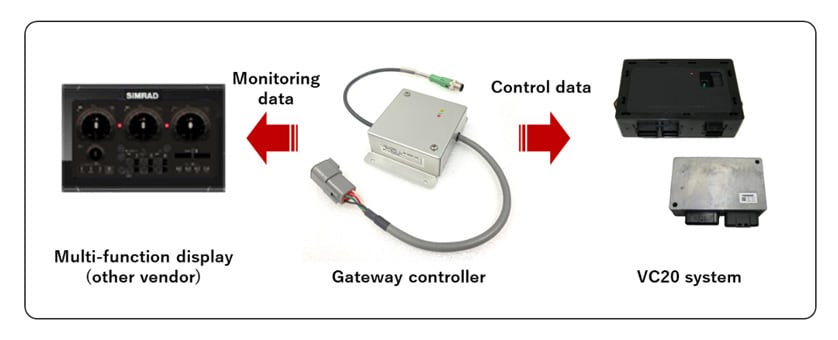

Yanmar has developed a new gateway controller to serve as an interface for CAN communications with equipment from other vendors. This controller was used, for example, to accommodate market demand for using a large multi-function display from a different supplier for vessel operation in place of the VC20 display (Fig. 7).

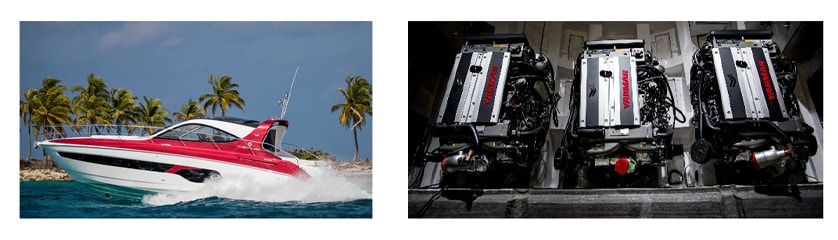

Both of these features are included on Yanmar’s flagship X47 powerboat (Fig. 8), earning a strong reputation for comfort and ease of use.

3) Minimum-spec model

Because sailboats only use their engine and propulsion unit when the wind is light or when entering or leaving the marina, they place fewer functional demands on their vessel control system. This is why, for cost reasons, such vessels have tended to use mechanical systems for this purpose. Unfortunately, the complicated cabling requirements of mechanical systems inside the vessel are a disadvantage when it comes to installation.

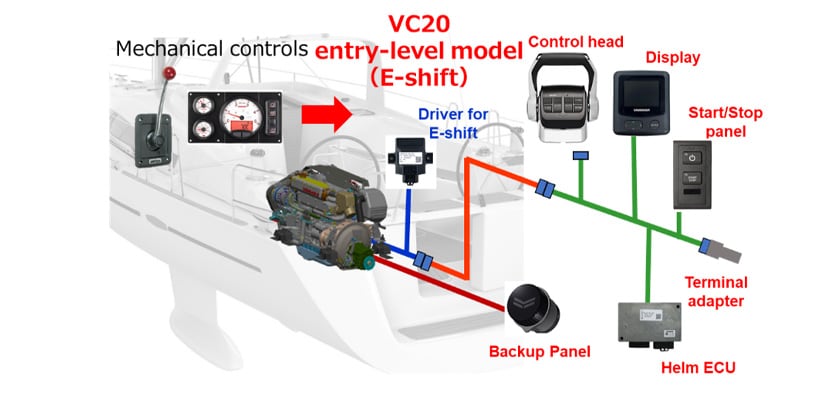

In response, Yanmar has included an entry-level model in the VC20 range that keeps the components and functions to a minimum, thereby providing a system that is purpose-designed for sailboats. This means that sailboats, too, can enjoy the ease-of-installation that is a major feature of the VC20 (Fig. 9).

3.2.Helm Controls Upgrade for Enhanced Design and Brand Image

The design of the area around the helm is an important consideration for a pleasure boat. Unfortunately, in terms of the sophistication and consistency of its visual appearance, feedback on the design of the VC10 helm controls was that they did not convey the brand image of Yanmar. With the VC20, Yanmar has expanded the scope of available designs by taking advantage of the use of CAN to downsize the hardware in the various helm devices. As a result, it has succeeded in developing helm controls with a consistent exterior design that embodies the Yanmar brand image, combining ease-of-use with sophisticated appearance (Fig. 10).

The result of this sophistication in visual design is that boats equipped with VC20 helms strongly convey the Yanmar brand image.

3.3.Ensuring Reliability and Safety

While electronic control systems typically rate very highly in terms of functionality compared to mechanical systems, ensuring reliability and safety is an important consideration given the precision electronic components they contain. The VC20 builds on system reliability and safety capabilities honed on the VC10 while also featuring additional enhancements.

The reliability of the VC20 helm controls has been enhanced through the use of highly durable materials and by improving waterproofing up to the IPX7 rating level. In the event that a system failure does occur, such as a failure in CAN communications, the user is still able to operate the vessel using the backup panel, which works on a separate system to CAN. This allows the vessel to return safely to port without having to shut down the engines.

4.Conclusions

This article has described the second-generation VC20 electronically controlled vessel control system featuring improved ease-of-installation, expandability, and strong visual design, while maintaining the safety and reliability Yanmar has developed over the years to support customers' comfortable operation of a wide range of vessels around the world. In its role as a provider of total marine solutions, Yanmar intends to use the VC20 as the basis for accelerating the creation of new value with the objective of providing customers with comfort, convenience, safety, and peace of mind.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Innovation & Technology Division, Technology Strategy Division.

Author