Marine Commercial - News Release

YANMAR Develops Fuel Efficient, Durable EY33 Series for Vessels

July 26, 2016

Yanmar Co., Ltd.

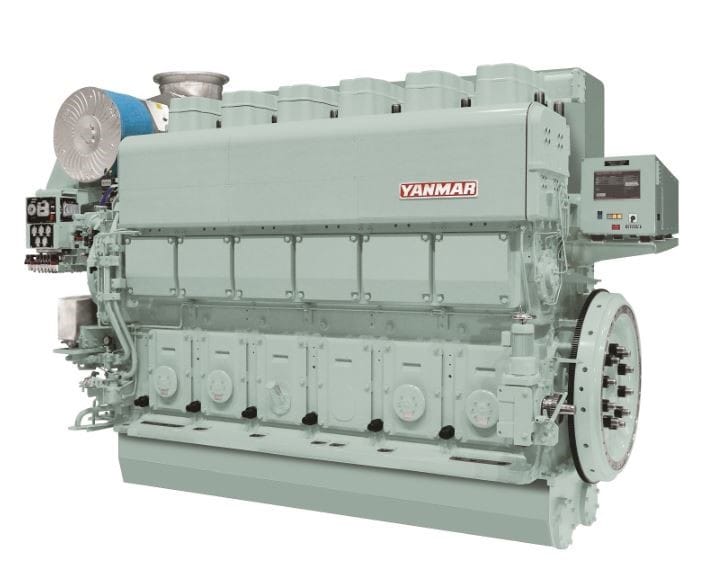

Delivering fuel efficiency and durability, YANMAR Co., Ltd.’s flagship engines for vessels, the EY33 series, is currently under development. The manufacturing phase for the auxiliary engines has already commenced, and the development phase for the propulsion engines is on its way towards completion.

Development for the EY series arose from YANMAR’s concept of Lifecycle Value and harmony with nature, which commenced in 2000. The latest engines developed boast the highest output of the series, delivering an optimized combustion performance and an enhanced load range under actual conditions, resulting in a 5% improvement in fuel efficiency compared to units from the previous YANMAR engine series. To meet International Maritime Organization (IMO) emissions regulations, nitrogen oxides (NOx) and CO2 have been reduced. Additionally, key components have been made more durable to allow for an increase in maintenance cycles from the previous 8,000 - 12,000hr to 12,000 - 15,000hr. With the EY series, YANMAR is intensifying its efforts towards minimizing environmental impact and improving life cycle value for its customers.

1. Key Features

Fuel Efficiency

-Leveraging advanced 3D simulations, combustion variables have been optimized

-Equipped with a high-pressure Miller cycle system that employs both a Miller-type camshaft* and a supercharger* that allows for high-pressure ratios; this system delivers reductions in NOx and CO2 emissions, in addition to greater fuel efficiency .

Durability Enhancements

-Pistons are constructed of two segments, employing alloy steel for the upper segment that is in direct contact during the combustion process

-The outer circumference of the piston ring contains a CPC coating, enhancing abrasion resistance and reducing seizures

-YANMAR's innovative processing for the inner surface of the cylinder liner improves oil retention, thereby reducing friction

-The exhaust valves employ a new alloy material that enhances abrasion resistance and durability

More Power

-The piston stroke length for the auxiliary engines has been increased from 380mm on previous models to 440mm

-The rated speed for the propulsion engines has been increased from 620min-1 on previous models to 750min-1

-Structural analysis has been performed on each part, with construction of the main parts and key moving parts optimized

*1: A camshaft with a design that allows for rapid closing of the intake valves

*2: Due to the rapid closing of the intake valves, this device pushes highly pressurized air through the cylinders, thereby offsetting pressure reductions inside of them

*3: A technology that applies aluminum to mitigate tiny cracks that arise in hard chrome plating

Inquiries

Public Relations Group

Brand Communication Division, Yanmar

E-mail: koho@yanmar.com

- Note: Information contained in the news release is valid at the time of publication and may differ from the most recently available information.