Industrial Power Products Management Division

Power System Operations Business

YANMAR Technical Review

Development of Oil Cooling Type Nitriding Nozzle for Large Diesel Engines

Abstract

Fuel injection nozzles for large diesel engines are required "High pressure injection", "Use in high temperature" and "Sulfuric acid corrosion resistance" .

Yanmar has already technologies for nitriding nozzles and oil cooling type nozzles. A new oil cooling type nitriding nozzle had been developed by combining these technologies.

The new nozzle has features that the surface hardness is higher by 30%, decreasing of hardness at high temperature is smaller and sulfuric acid corrosion is less by 80% comparing with current carburizing nozzles.

It is applied to the new Yanmar diesel engine "EY33" of which power and injection pressure are significantly upgraded and further application to the dual-fuel engine with higher operating temperature is expected.

1.Introduction

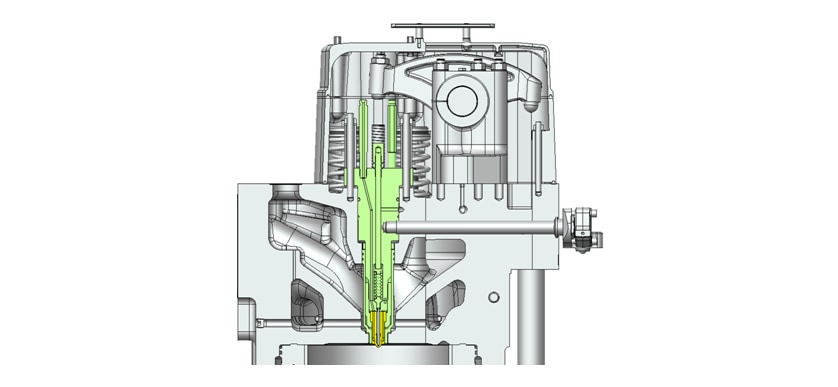

In recent years, in addition to compliance with exhaust gas regulations, improved fuel economy, increased LCV (Life Cycle Value) and higher output have also been requirements for large diesel engines. To achieve this, higher fuel injection pressure, use in high temperature environments and a longer service are now required for fuel injection systems. This article describes the development of an oil cooling type nitriding nozzle as one example of meeting these requirements with the fuel injection nozzle (Fig. 1 shows a cross-sectional view of a fuel injection nozzle assembled to the engine cylinder head).

2.Characteristics Required for Large Diesel Engine Nozzles

The following characteristics are required for fuel injection nozzles in large diesel engines.

(1) High pressure injection

To improve the combustion performance of diesel engines, high pressure injection is required in order to atomize the fuel spray of the fuel injection system. As a result of this, the allowable pressure of the fuel injection nozzle must also be increased.

(2)Use in high temperature environments

As previously shown in Fig. 1, the tip of the fuel injection nozzle is exposed in the combustion chamber and at a high temperature due to the engine combustion. As engines with higher outputs are developed, the nozzle tip is used in even higher temperature environments. In addition, HFO (Heavy Fuel Oil) is used as the fuel in large engines. Because HFO has high viscosity at normal temperatures and cannot be used as-is, the fuel temperature must be raised to reduce the viscosity to a certain level. The effect of this fuel temperature increase also raises the nozzle tip to a high temperature.

As a result, it became necessary to be able to use the fuel injection nozzle in high temperature environments without any decrease in its wear resistance.

(3)Sulfuric acid corrosion resistance

When HFO is used as the fuel, the sulfur content in the HFO generates sulfur trioxide due to combustion. This reacts with the water vapor to form sulfuric acid vapor inside the combustion chamber. Under the dew point temperature, the vapor forms sulfuric acid and corrodes the fuel injection nozzle (low temperature sulfuric acid corrosion). Therefore, the fuel injection nozzle must be resistant to sulfuric acid corrosion.

3.Development of Oil Cooling Type Nitriding Nozzle for Large Diesel Engines

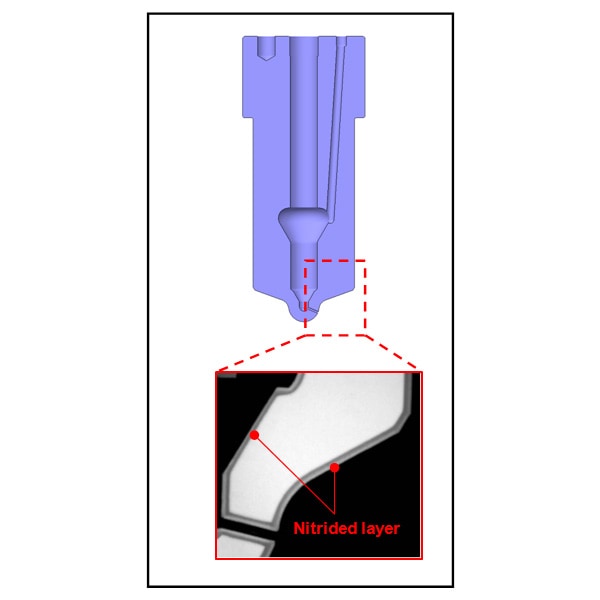

In addition to nozzles with the usual carburizing treatment, Yanmar has been mass producing nitriding nozzles. Fig. 2 shows a cross-sectional view of a nozzle produced with the nitriding treatment.

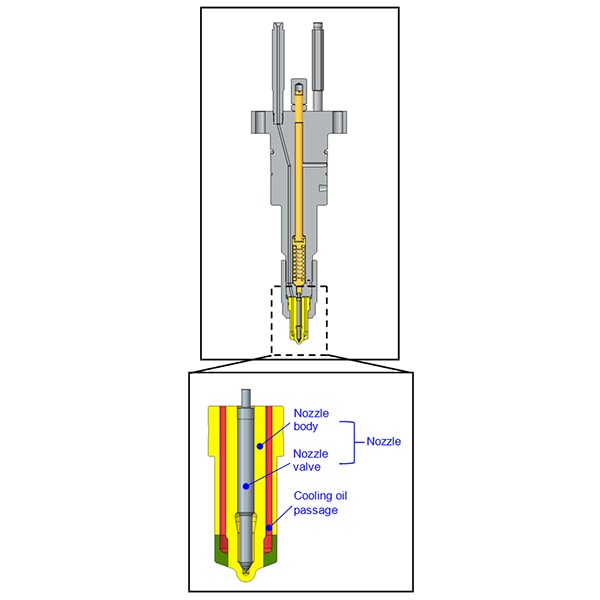

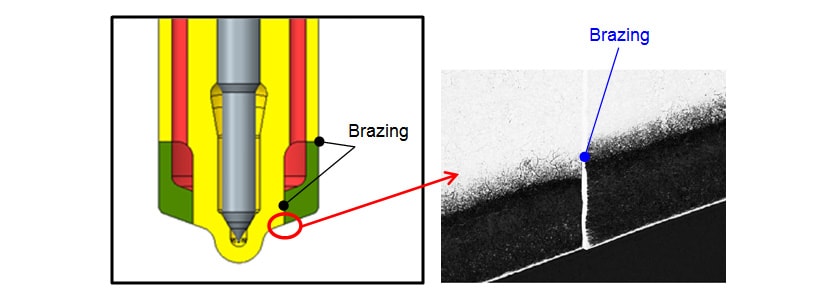

Yanmar also mass produces carburized oil cooling type nozzles for large engines (Fig. 3 shows the cross-section of an oil cooling type nozzle). The oil cooling type nozzle has a structure whereby the nozzle body is cooled by circulating cooling oil inside the nozzle.

3.1.Comparison of Nitriding and Carburizing Nozzles

Nitriding nozzles have the following advantages compared with carburizing nozzles.

(1)Comparison of resistance to high pressure injection

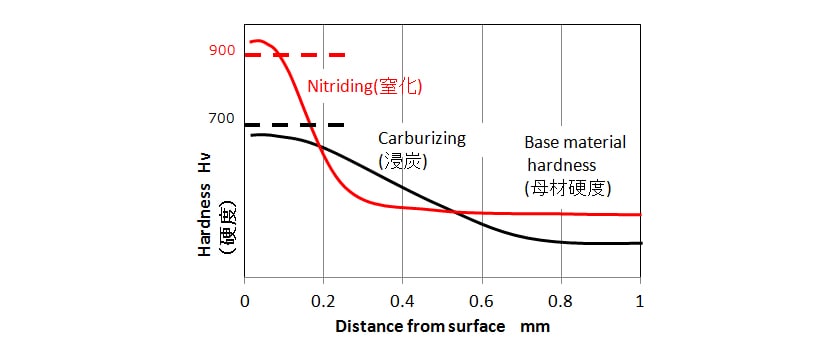

Fig. 4 compares the hardness distribution of nitriding nozzles and carburizing nozzles. Compared to the 700 Hv surface hardness level of carburizing nozzles, the 900 Hv hardness level of nitriding nozzles is approximately 1.3 times higher, and the base material hardness is also higher. This increases the fatigue strength, enabling operation at higher injection pressures. The higher surface hardness also increases wear resistance.

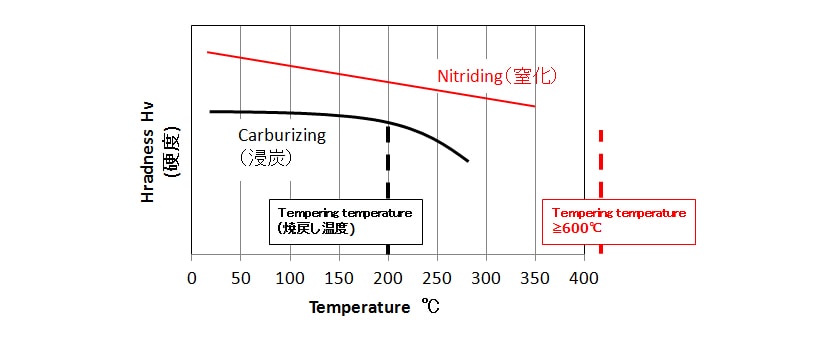

(2)Comparison of hardness in high temperature environments

Fig. 5 shows the results of hardness measurement for nitriding and carburizing nozzles as the temperature was changed. The hardness of carburizing nozzles drops significantly when the tempering temperature is exceeded, which prevents use in temperature environments higher than the tempering temperature. In contrast, the hardness of nitriding nozzles does not drop much at high temperatures. As a result, use in high temperature environments is another advantage of nitriding nozzles compared with carburizing nozzles.

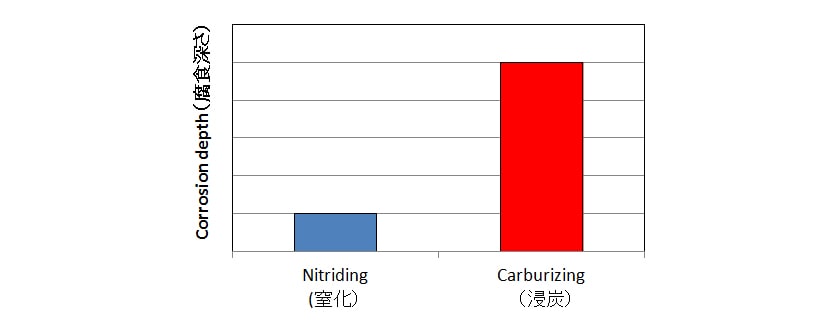

(3)Low temperature sulfuric acid corrosion resistance

The nitriding treatment forms a compound layer on the outmost surface of the nitrided layer of the nozzle body (see the previous Fig.2). This compound layer increases the corrosion resistance. Fig. 6 shows the results of an immersion test in a sulfuric acid aqueous solution. The corrosion depth of nitriding nozzles is approximately 1/5 of carburizing nozzles, giving nitriding nozzles an advantage in terms of sulfuric acid corrosion resistance as well.

3.2.Development of Oil Cooling Type Nitriding Nozzles

As described above, Yanmar has for some time been mass producing nozzles with an oil cooling structure. However, previously this structure has only been used for carburizing nozzles. In our newly developed EY33 engine, output has been increased, and a new fuel injection system is used that increases the allowable injection pressure from the previous 150 MPa to 180 MPa. For this reason, nozzles were required that can withstand high pressure and can be used in high temperature environments. Therefore, an oil cooling type nitriding nozzle had been newly developed by incorporating nitriding nozzle technology into an oil cooling structure.

A subject during the development was low machinability because nitriding steel has good hardenability, a nozzle was hardened in the brazing process. In response, the heat treatment process was reviewed to improve machinability, and then the strength of the brazed areas and the characteristics of the nitriding nozzle was secured.

By using these oil cooling type nitriding nozzles to ensure proper nozzle cooling, any decrease in hardness was prevented and strength and wear resistance were achieved.

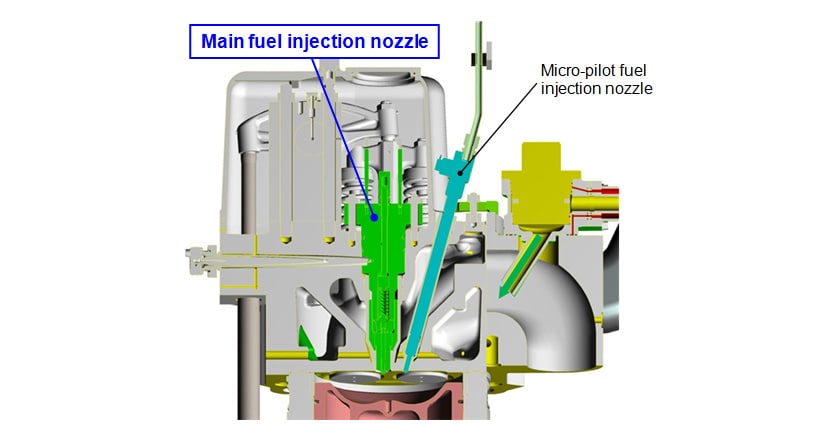

4.Application in Dual Fuel Engines

In the dual fuel engines for marine use described in the Summer 2015 YANMAR Technical Review, fuel is injected from the micro-pilot fuel injection nozzle during gas operation mode, without being injected from the main fuel injection nozzle. Therefore, there is no cooling effect due to fuel injection, and the nozzle tip is exposed to high temperatures.

For this reason, the main fuel injection nozzle for dual fuel engines is considered to be used in even higher temperature environments than before, resulting in the need for the oil cooling type nitriding nozzle.

5.Conclusion

Yanmar is one of the few diesel engine manufacturers that develops and manufactures its own fuel injection systems. We also have a Material Research Group at our Research and Development Center. During product development for this oil cooling type nitriding nozzle, our Research and Development Center, manufacturing departments and development departments cooperated to drive forward development toward mass production. In this way, related departments at Yanmar come together to proceed with product development. In the future we will continue to utilize our total solutions to develop products that increase life cycle value.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Research & Development Management Division.

Author