Tuff Torq Corporation R&D Department

YANMAR Technical Review

IHT the Top-share Transaxle for Lawn Tractors

Abstract

An integrated hydrostatic transaxle (IHT) consists of a hydrostatic transmission (HST) and gear drive train in one housing. IHTs are mainly installed on the ride-on lawnmowers used in the US and European markets, where large decorative lawns are common. This article describes the Tuff Torq brand of IHTs, the top share in the US market.

1.Introduction

The integrated hydrostatic transaxle (IHT), which consists of a hydrostatic transmission (HST) and gear drive train in one housing, was first in the world developed and commercialized by Kanzaki Kokyukoki Mfg. Co., Ltd. and Tuff Torq Corporation (TTC).

IHTs are mainly installed on the ride-on lawnmowers and are widely used in North America and Europe, where large decorative lawns are common (see Fig. 1).

This article describes the Tuff Torq brand of IHTs, the top share in North America.

2.Basic Constitution of IHT

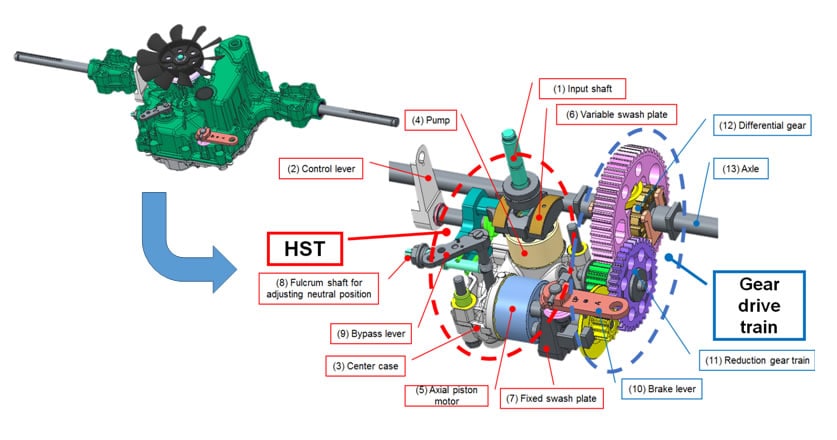

An IHT is constituted of an input shaft (1) that transmits engine power to the HST, a control lever (2) that controls the direction and speed of the lawnmower, and the HST components. These HST components include the center case (3), axial piston pump (4) and electric motor (5), variable (6) and fixed (7) swash plates, eccentric shaft (8) for adjusting neutral position, bypass lever (9) for forcibly releasing the hydraulic brake, parking brake lever (10), reduction gear train (11), differential gear (12), and axle (13). As shown in Fig. 2, Tuff Torq brand IHTs are designed to be compact for ease of installation on the lawnmower, with aluminum and sintered metal used for major parts to achieve lighter weight and lower price.

3.Product Range of Tuff Torq Brand IHTs

IHTs can be broadly divided into two categories. One category is suitable for light-load applications such as lawn mowing or short-duration use of a blade. The other is for heavy-load applications such as plowing.

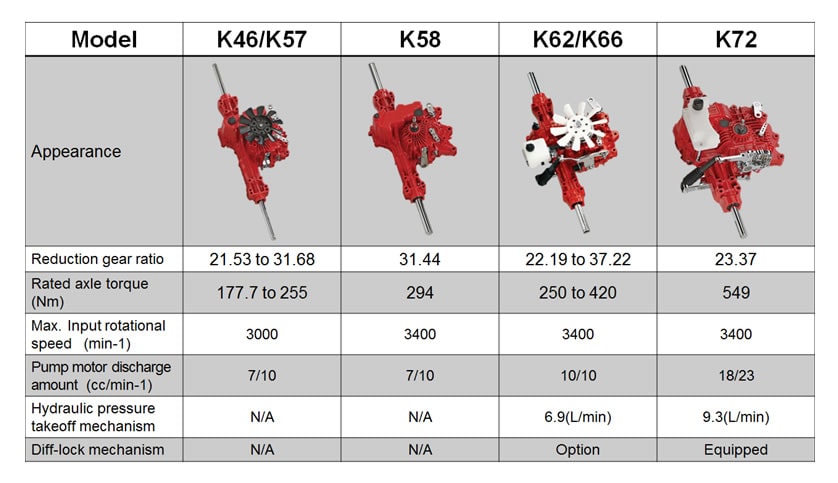

TTC provides six models, three each for light- and heavy-load applications.

Models for heavy-load

- K46: Simple basic model

- K57: Installs a charge pump to the K46 for higher HST efficiency and longer life

- K58: Premium model with higher load capacity from K57

Models for heavy-load

- K62: Simple basic model. A diff-lock option is available.

- K66: Installs a hydraulic pressure takeoff mechanism to the K62

- K72: Flagship model with higher HST capacity and designed for lower noise and longer life

This product range covers diverse customer needs (see Table 1).

Table 1 Specifications

4.Features of Tuff Torq Brand IHTs

4.1.High Applicability

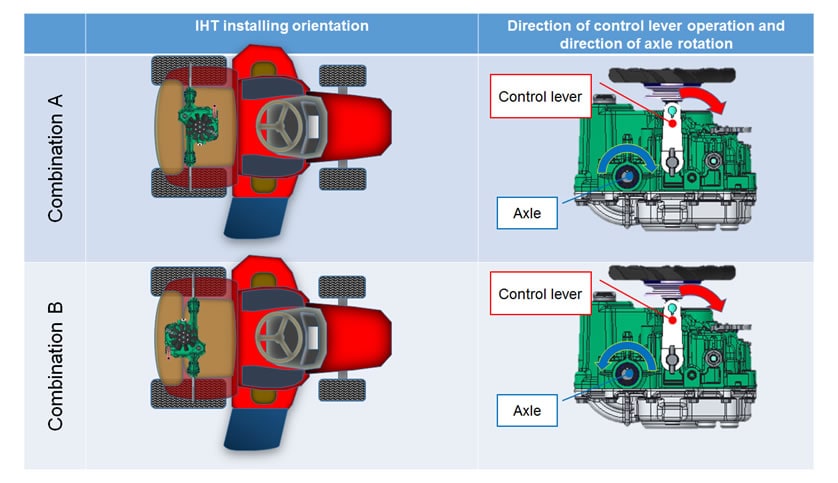

Various customers use different IHT installing orientations and different directions of operation for the control lever that controls the direction of lawnmower movement (forward or backward), with two different options for installing orientation and two for control lever orientation, giving a total of four combinations (see Fig. 3).

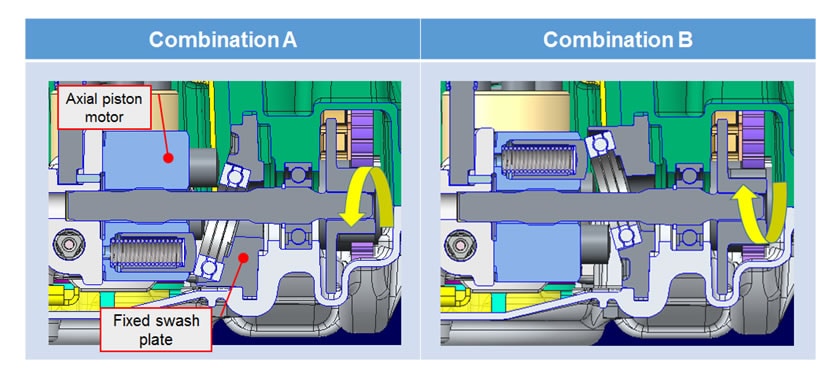

To achieve this flexibility the angle of the fixed motor swash plate would be reversed. The TTC brand IHT adopts a symmetric fixed motor swash plate that can be reoriented during assembly. Therefore all four combinations can be easily achieved using the same major parts, it provides a design that is both economical and applicable enough to satisfy various customer requirements. As this means that all four combinations can be easily achieved using the same major parts, it provides a design that is both economical and applicable enough to satisfy various customer requirements (see Fig. 4).

4.2.Internal Damping System (IDS)

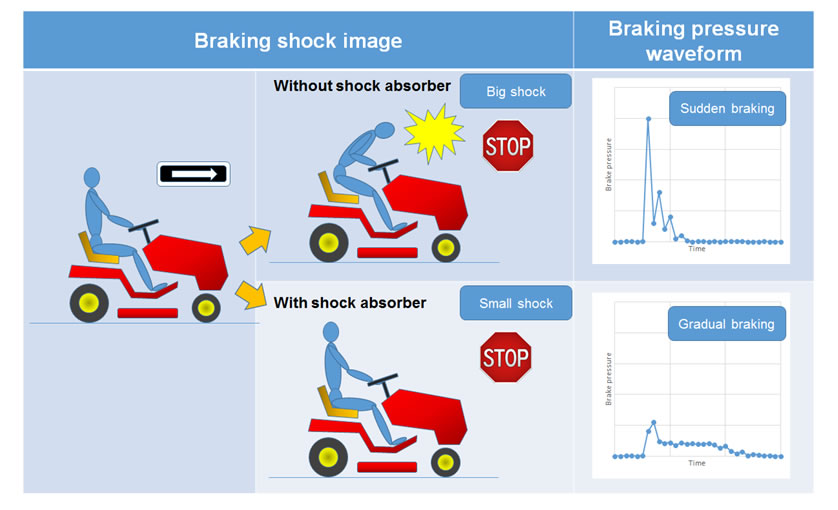

When the pump-side variable swash plate on the HST is in the neutral position, the containment of the hydraulic oil causes brake action. Accordingly, this will result in sudden braking when the control lever (variable swash plate) is quickly shifted back to the neutral position while the lawnmower is traveling. Because this brings a negative influence on riding comfort, the following methods are normally adopted (see Fig. 5):

① Apply an oil damper for the control lever to slow down moving speed to the neutral position.

② Provide an orifice in the hydraulic circuit of the HST to deliberately weaken brake action by bleeding off hydraulic oil.

The first method tends to be adopted on high-end models because it provides a much better feeling, however the shock absorber is costly. In contrast, while the second method can be implemented at low cost, it inevitably results in a loss of efficiency due to leakage of hydraulic oil from the HST.

Accordingly, IDS was developed to provide a low-cost means of preventing sudden braking that also minimizes loss of efficiency. (IDS has already been patented.)

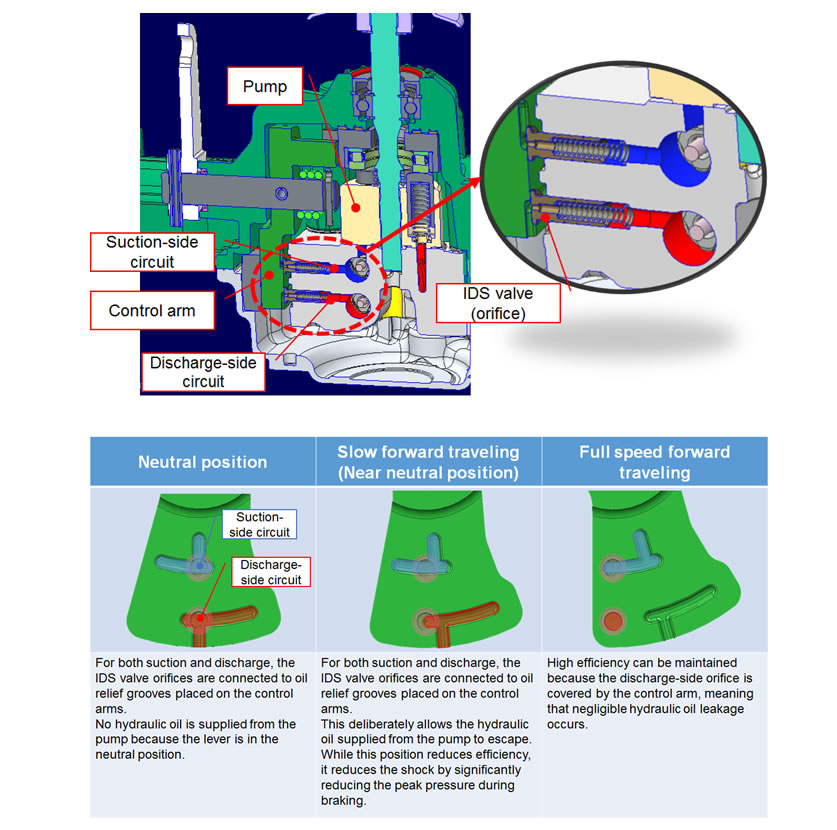

As with the second method, IDS basically works by providing an orifice in the hydraulic circuit, but it prevents the loss of efficiency by capping the orifice in traveling areas. While, the orifice is only open to reduce brake action when the swash plate is close to the neutral position (see Fig. 6).

IDS has been favored by a large number of customers for its good balance between cost and performance, therefore IDS has been installed on the majority of K46 models.

5.Conclusions

As noted in the introduction, Tuff Torq Corporation has the top share of the market for transaxles for ride-on lawnmowers in North America, and believes this is the result of its continuing to think about the values and issues for customers, and offering solutions by actively taking on new challenges without fear of failure.

Without being satisfied with the current state, Tuff Torq Corporation in its role as the market leader intends to continue striving to deliver a wider range of products that is delighted and pleased by customers at the best timing.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Research & Development Management Division.

Author