Engineering Department

YANMAR CONSTRUCTION EQUIPMENT EUROPE S.A.S.

YANMAR Technical Review

Product Technology Overview for New SV60 Excavator: Designed for Business Class Levels of Comfort

Abstract

Yanmar produces two series of hydraulic excavator, the ViO and SV, of which the ViO is a "true zero tail swing" excavator with no overhang of the rear of the superstructure. This makes the ViO series well suited to urban and other confined worksites. The SV, on the other hand, provides excellent practicality at sites where more space is available. This article describes the development of the new SV60 excavator targeted at the European market and designed to provide a business class level of comfort.

1. Introduction

The most common type of hydraulic excavator in Yanmar's range is the ViO series of "true zero tail swing" models in which the rear of the superstructure does not overhang the crawlers when swinging, providing a high level of safety. This feature is one of the reasons why the ViO series has enjoyed a good reputation with users over the many years since it first went on sale and is commonly used on urban or other worksites where space is limited. Along with these true zero tail swing excavators, Yanmar also produces the SV series of excavators that are based on a different concept, with the emphasis instead placed on stability and comfort. The SV series are Yanmar's standard product in Europe. The main features of the SV series are that they are roomier than the ViO series and have excellent stability. Although the design is such that the rear of the superstructure does overhang the crawlers when swinging, there is strong demand for this configuration in Europe where use of large attachments and larger bodied operators are more common. As the ViO series is the mainstay of Yanmar's product range, there is an urgent need to offer a wider range of SV series models. It is against this background that the new SV60 excavator described on this article is to be launched on the European market.

2. Product Overview

Fig. 1 SV60 (Left) and ViO55-6 (Right) Excavators

The objective for this excavator was to provide a top-class level of comfort beyond that of previous models.

Fig. 1 shows the new SV60 excavator (left) and the existing ViO55-6 excavator (right). The new SV60 uses the same visual design features as the ViO55-6 that first went on sale in 2013, following a concept adopted for all -6 series models. It features enhanced comfort with a spacious cabin that is of a size found on excavators of one rank higher class. Its hydraulic performance matches that of the very popular ViO55-6, and it features improved efficiency in terms of fuel consumption and working performance. The following sections describe the features of the new SV60.

3. Features

3.1. Comfort

European users tend to be larger bodied than Japanese and are very demanding not only about hydraulic excavator performance, but also about comfort and convenience. One of the reasons why excavators of this type have such a large share of the European market is said to be the comfort they provide.

Accordingly, Yanmar set out to provide more space for operation and to improve convenience, including the cabin shape. The first step was to increase leg room by about 80 mm compared to previous models and to enlarge the cabin entrance to make getting in and out easier. Providing retractable travel pedals from models one rank higher made pedal operation of the travel control lever easier. The space inside the cabin is the same as for models one class higher, ensuring top-class spaciousness. With storage space being a feature in strong demand, the cabin was provided with a large region behind the seat with plenty of room for a lunchbox, cup holders able to fit large sizes of plastic bottle, a mobile phone holder, and space for storing magazines and other objects.

Yanmar used universal design (UD) to conduct detailed investigations into the ergonomically designed shape of the entrance door handle and a button layout that ensures that all buttons can be operated from the seated position. A diverse range of options are also available to adapt the excavators to suit various different customer demands. The new SV60 is designed with both comfort and safety in mind, with an LCD monitor and rear-view camera included as standard features to provide a safe view of the rear of the excavator.

3.2. Stability

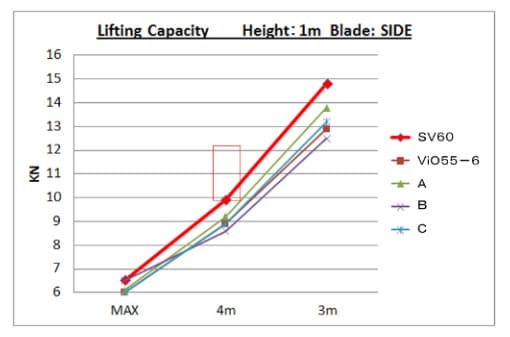

Lifting capacity is one of the most important performance factors for an excavator. The ability to lift heavy soil or other loads with ease without becoming unbalanced at worksites or other locations brings major advantages for customer productivity. It also provides the capability to fit the numerous heavy attachments used in the European market. Accordingly, Yanmar conducted benchmarking to set targets for these features. The competing products (indicated by A, B, and C in Fig. 8) used as benchmarks were all standard models.

Through the use of calculations based on component masses and layout, these targets were mostly achieved.

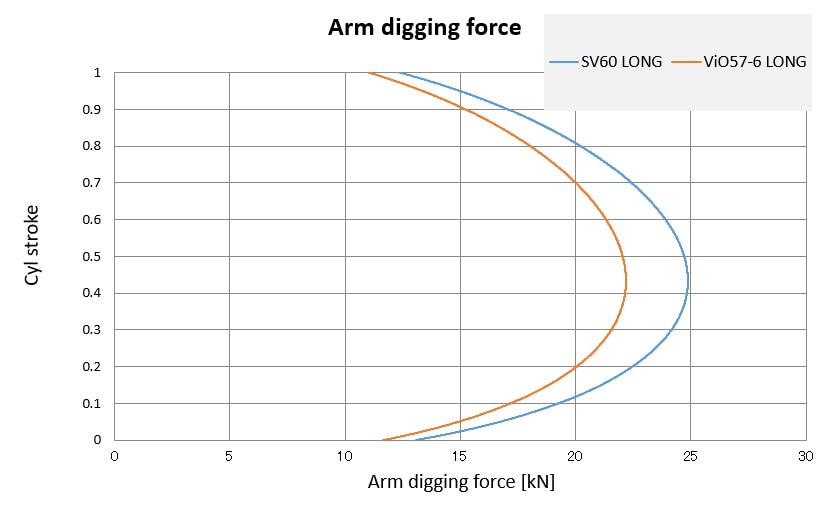

Digging force is another important performance factor.

The target set for the new SV60 was to increase the arm digging force compared to previous models.

While the nature of moment of force means that the digging force falls as the arm gets longer, the new SV60 succeeded in achieving an adequate digging force despite having a working radius that is one of the best in its class.

3.3. Maintenability

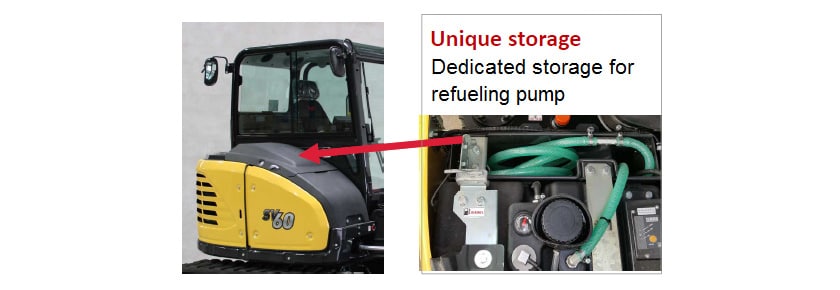

Because the relative positions of the engine and the cooling devices such as the radiator and hydraulic oil cooler follow the same concept as in the ViO55-6, the design provides for tool-less opening and closing of the rear bonnet and one-side maintenance from the right rear. Battery replacement is a simple procedure that involves opening the right bonnet and the cover under the duct. Similarly, access to fuel and hydraulic oil replenishing and replacement of the air cleaner element is also a simple matter of opening the plastic cover on the right. An automatic refueling system is provided as a standard feature, making routine fueling easy. The fuel tank is approximately 1.5 times larger than on the ViO55-6, providing longer operation and reduced downtime.

4. Conclusions

The new SV60 excavator was developed by a joint project in Japan and France in which those involved worked together to overcome a variety of challenges encountered during its course. Yanmar is confident that customers will get a sense of the spaciousness and comfort of the new model as soon as they get inside. Yanmar intends to continue supplying products that satisfy its customers.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Research & Development Management Division.

Author