Development Dept.

KANZAKI KOKYUKOKI MFG. CO., LTD.

YANMAR Technical Review

Technologies Used in HMT Unit for Corn Harvesters for the Chinese Market: A Behind-the-Scenes Mechanism with an Important Role in End Product Performance

Abstract

A hydraulic-mechanical transmission (HMT) combines planetary gears with a hydrostatic transmission (HST). Yanmar has now developed a new product that integrates these into a single unit.

Called the HMT unit, it is designed to fit in existing transmissions without significant changes to the drive train layout.

The HMT unit improves the operation, performance, and efficiency of the machinery in which it is installed, and it has been fitted in wheat and corn harvesters launched on the Chinese market in 2018.

Yanmar is currently awaiting user feedback.

1. Introduction

Along with reforms to the sector's economic systems, agriculture in China has entered a phase in which mechanization predominates. Use of machinery is growing and it is progressively becoming the mainstay of agricultural production. This is also being accompanied by a strengthening trend toward agricultural efficiency improvements (labor saving and cost reduction).

While past mechanization has primarily involved crawler-driven machines for harvesters, with growing use of hydraulic static transmission (HST), there is also rising demand for HST in self-propelled harvesters. This article describes a hydraulic-mechanical transmission (HMT) unit for wheat and corn harvesters developed by Yanmar to meet this need.

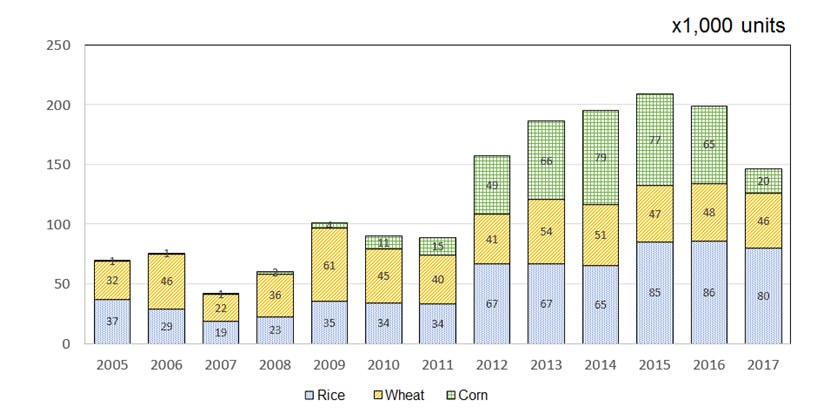

2. Chinese Cropping Market

China has adopted agricultural policies that have accelerated the pace of mechanization in order to alleviate the sector's labor shortages arising from the large-scale urbanization that started in the late 1990s. While HST is already used in harvesters, especially the crawler-driven machines used for rice harvesting, the market for corn has expanded rapidly since 2012, reaching a size that puts it on a par with rice. Although production controls were imposed in 2017 as a measure intended to deal with growing stockpiles, it is anticipated that rural development policies by the government will lead to a recovery in the market (see Fig. 1).

Source: China Associatyion of Agricultural Machinery Manufactures

3. HMT Overview

Hydraulic transmissions that work by hydraulics can be divided into a hydraulic static transmission (HST) in which the hydraulic pump and motor are linked by an oil line only, and a hydraulic mechanical transmission (HMT) in which the drive power is transmitted both hydraulically and mechanically. In general, while HST is able to provide an optimal speed ratio over all speed ranges, because the power is transferred by hydraulics alone, factors such as leakage make for low transmission efficiency. Nevertheless, HST is widely used in construction, agricultural, and other machinery because no constraint on output shaft location allows the system to be packaged into a small housing. HMT, in contrast, a part of the pump drive torque and the output torque of the hydraulic motor are added. This allows HMT to operate with higher transmission efficiency and transmitted power than those of HST.

HMT was first commercialized for a large tractor in 1995. Yanmar began selling agricultural machinery with HMT in Japan initially, then overseas. While it can be thought of as a mature technology, a HMT configuration suitable for all applications has yet to be established.

4. Configuration of HMT Unit

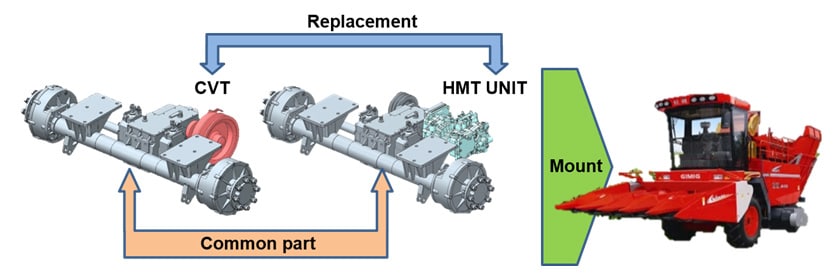

The new HMT unit is an integrated unit that combines an HST in the hydraulic drive section and a planetary gear in the power splitting mechanism. This integrated design makes it suitable for use in a wide variety of mechanical transmissions (see Fig. 2).

A cost-advantage of the drive system is that the transmission can use mostly the same components as a mechanical CVT (continuously variable transmission). The unit also has the same mounting as previous transmissions, making it suitable as a replacement for these in production models (see Fig. 3).

5. Design of HMT Unit

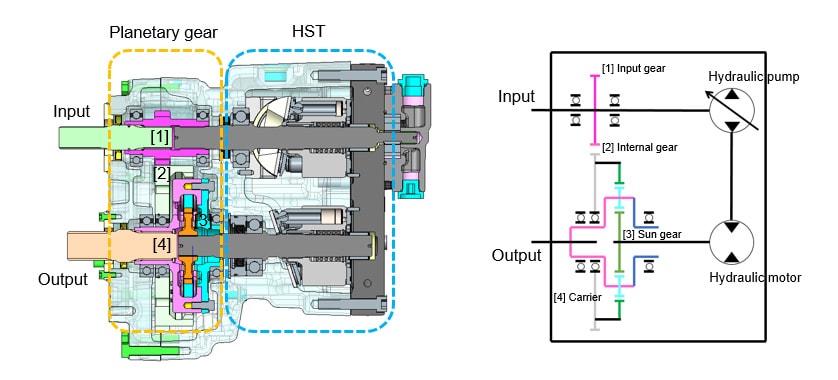

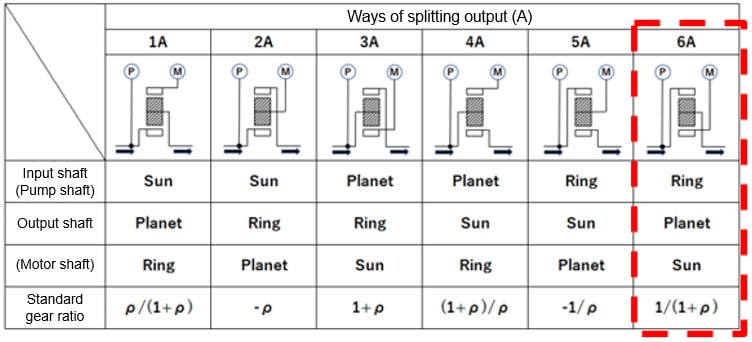

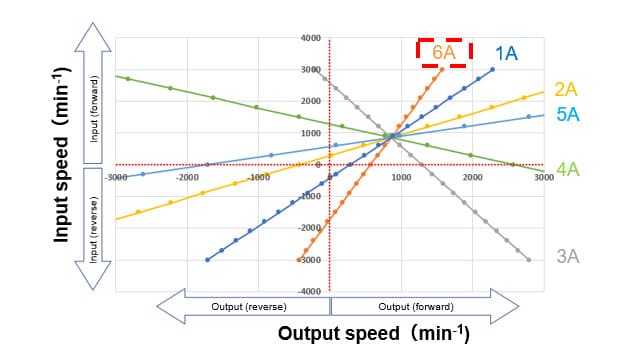

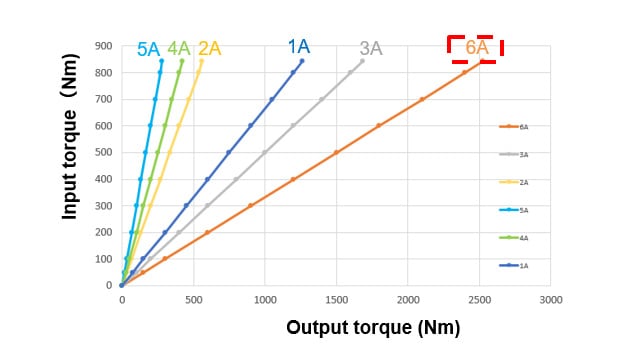

As explained above, the HMT works by adding a part of the pump drive torque and the output torque of the hydraulic motor, and this can be done in a total of 12 different ways depending on the combination of input splitter, output splitter, and gears. This is explained below with reference to Fig. 4, which shows the design chosen for the new HMT unit.

The engine power, which is transmitted to the input gear ([1]), is split into mechanical transmission path (via the planetary gear) and hydraulic transmission path (the HST pump).

In the mechanical transmission path, power transmitted from the input gear ([1]) to the internal gear ([2]) of the planetary gear unit is output via a pinion gear from the carrier [4].

In the hydraulic transmission path, the hydraulic power from the hydraulic pump is converted to mechanical power by the hydraulic motor and transmitted to the sun gear ([3]) and then output via the planetary gear unit.

As total power is the sum of mechanical and hydraulic power, the HMT unit can achieve both high transmission efficiency and high power. This design corresponds to power splitting method 6A in Table 1 below.

Table 1 Six Different Power Splitting Methods

Option 6A was chosen as the best method to satisfy the requirements by comparing the input and output speeds and torques of the six different power splitting methods based on the speed ratio (see Figs 5 and 6).

6. Performance Evaluation

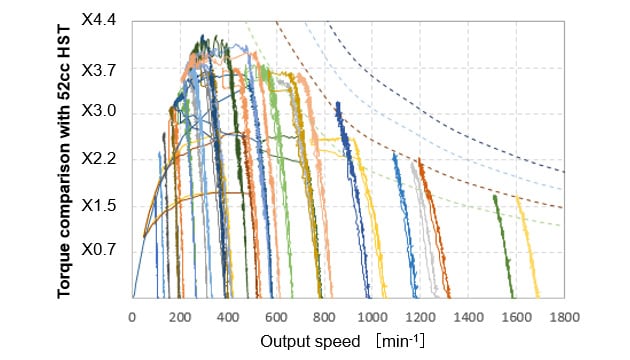

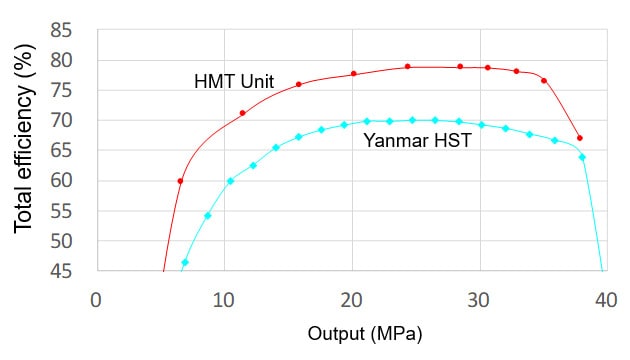

The power map in Fig. 7 shows the maximum power of a single unit was increased by approximately four times by replacing the 52 cc HST by the HMT. A high total efficiency of 79 % was also achieved, against a value of 70 % for Yanmar's HST (see Fig. 8).

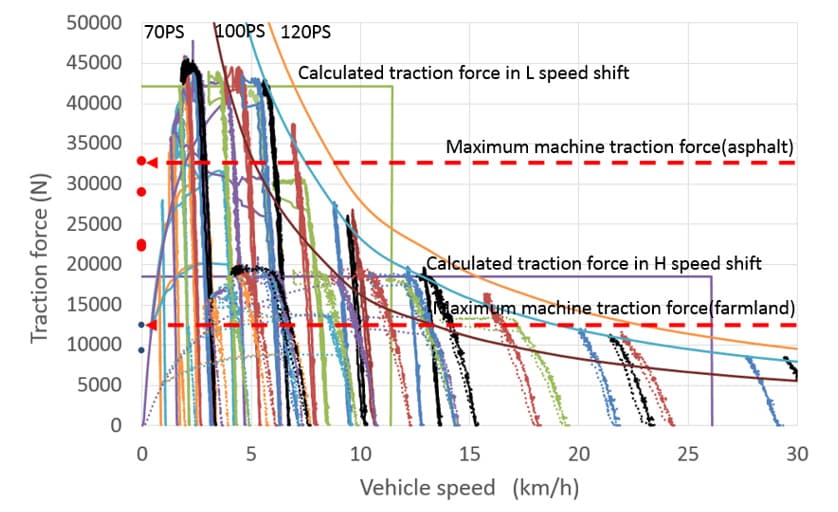

The performance of the HMT unit when installed in a working machine is such that it can provide power equivalent to 100 PS in drive system. The traction force measurements on a 6800 kg machine driving on asphalt and farmland shows a margin of approximately 1.3 times, indicating that the unit can be used in machines of up to 9000 kg (see Fig. 9).

7. Conclusions

The new HMT unit went into full production in February 2018 and is being fitted to wheat and corn harvesters for the Chinese market. Although the company is still awaiting feedback from users, initial reports have been positive. It is anticipated that production and sales will increase in the future.

The new HMT unit combines the existing technologies of planetary gears and HST in a single unit, and its purpose and value become apparent in practical use (when incorporated into a transmission and fitted in a machine). Although components such as the HMT do not draw an end user's attention, they are important parts which decide the performance of the machinery. Yanmar intends not only to continue improving hydraulic and transmission technology, but also to pay attention to the form taken by its end products (machinery) as it goes about developing products that offer ways of giving customers what they need based on an understanding of what these needs are.

References

Kuniyasu Nagatomo, Hydraulics & Pneumatics 2001.3, Japan Industrial Publishing

Kanto Branch, Japan Society of Mechanical Engineers, Yamanashi Proceedings of The Japan Society for Precision Engineering

Authors: Kouichi Masuzawa (Tokyo University of Technology, Graduate School), Ken Ichiryu (Tokyo University of Technology)

Shandong Juming Group website: http://www.sdjuming.com/

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Research & Development Management Division.

Author