Bio Innovation Center Marine Farm

From fishing to aquaculture: a next generation marine research facility

The sea is the source of all life. However, with ever increasing demands on the world's fisheries leading to a depletion of natural resources and threatening the sustainable use of the worlds oceans, there are high hopes for development of the aquaculture industry. In particular, cultivation of bivalve shellfish such as short-necked clam, oyster, etc. is attracting a great deal of attention as an example of sustainable aquaculture. Because the shellfish do not require feeding, costs are low, as is the environmental impact on the surrounding ocean. The "Bio Innovation Center Marine Farm" is looking to the future, utilizing the latest technology to advance bivalve cultivation around the world, towards preservation of the environment.

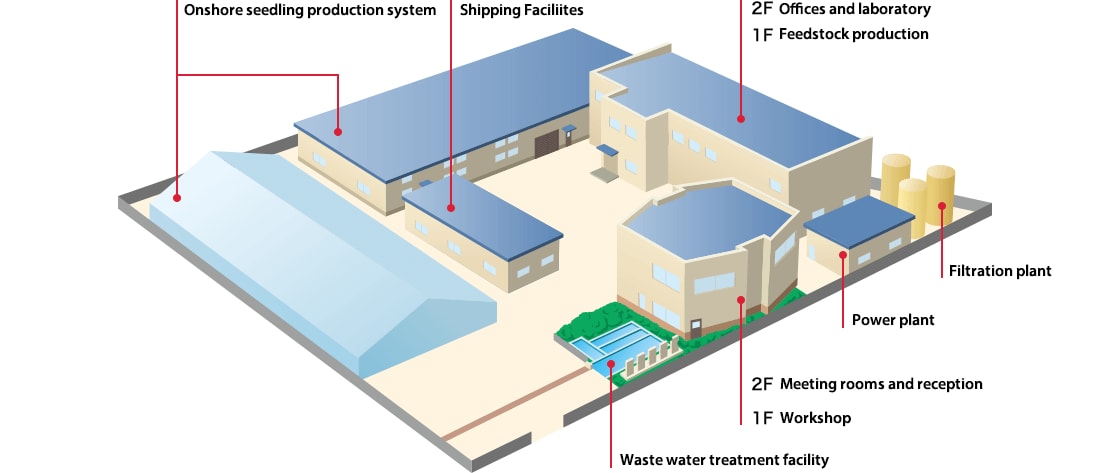

Bio Innovation Center Marine Farm Facility

Our Businesses

By utilizing advanced proprietary technologies, and thorough production control, Yanmar produces and supplies high quality live feedstock and bivalve seedlings (spats).

Feedstock Sales Business

In 2003 we established Japan's largest indoor feed production facility, utilizing advanced automation of alga culture technology. Grown under strictly controlled conditions, feedstock for oyster, long-neck clam, sea urchin and sea cucumber production is supplying aquaculture production test facilities and contributing to the development of the fisheries industry.

Through carefully management of the harvest cycle and utilization of our proprietary enrichment technology Yanmar can offer a concentrated and easy to use high nutrient feedstock.

Concentrated feedstock (100 million cells/ml)

Chaetoceros gracilis

Bivalve Shellfish Sales Business

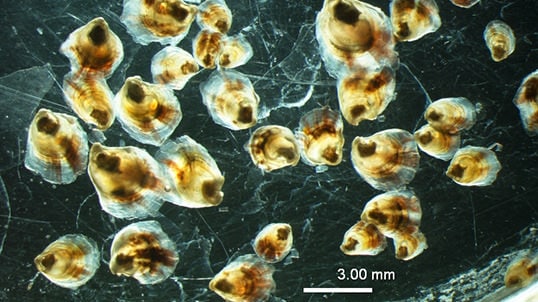

We're also supplying high quality single-seed type oyster spats (2mm) that are ready to be farmed, and working towards recovery of the declining stocks of the long-necked clam by providing a safe and stable supply of clam seedlings and spats (around 1 mm).

Long-neck clam spats

Oyster spats

R&D

With a view to creating a new aquaculture which contributes to improvement in the profitability of fisheries, Yanmar has developed a comprehensive aquaculture system, from spat production to shipment based on oyster size, around the core technology of bivalve seedlings and spat production, and has developed associated technologies to support this enterprise.

Feedstock Production Technology

Algae is gaining attention as a possible solution to various problems, from global warming, and environmental pollution, to food and energy shortages. As well as its use as a feedstock for bivalve shellfish aquaculture, it also has applications in fields as varied as medicine and as a biofuel supplements. Indeed, development into innovative uses of algae continues with ongoing research into its photoenvironment.

Seedling Technology

Establishment of aquaculture technology capable of delivering a safe and stable food supply is driven by the need to support declining fisheries resources and create new value, through the sustainable production of marine resources. In particular, Yanmar is engaging in trials of indoor aquaculture with microbial algae feedstocks and careful management of parent oyster stocks to deliver added value, and a safe and reliable oyster production process.

Aquaculture Technology

In order to realize a highly profitable aquaculture, oysters can continue to be produced on the surface of the sea, or on tidal flats, using artificially produced oyster spats and seedlings. Yanmar cultures the seedlings in a floating raft-type nursery vessel or FLUPSY (Floating UPweller SYstem). Moreover, in order to enable the year-round supply, in addition to the common oyster, research continues into production by aquaculture of other varieties of oyster and bivalve shellfish, as well as post-harvest sanitization technology.

Facility Location

3286 Itohara, Musashi-cho, Kunisaki, Oita Prefecture, Japan, 873-0421

Agriculture Equipment

Agriculture Equipment Compact Equipment

Compact Equipment Utility Task Vehicles

Utility Task Vehicles Industrial Engines

Industrial Engines Recreational Marine

Recreational Marine Marine Commercial

Marine Commercial Propulsion Engines (High Speed)

Propulsion Engines (High Speed) Propulsion Engines (Medium Speed)

Propulsion Engines (Medium Speed) Auxiliary Engines

Auxiliary Engines SCR System

SCR System Dual Fuel Engine

Dual Fuel Engine Two-stage Turbocharging System

Two-stage Turbocharging System Electric Propulsion System

Electric Propulsion System Net Cleaning Robot

Net Cleaning Robot Energy Systems

Energy Systems Compact Power Products

Compact Power Products YANMAR RePower

YANMAR RePower Genuine Parts

Genuine Parts