YANMAR KOTA KINABALU

R&D CENTER SDN. BHD.

YANMAR Technical Review

Introduction to Yanmar Kota Kinabalu R&D Center (YKRC)

1.Introduction

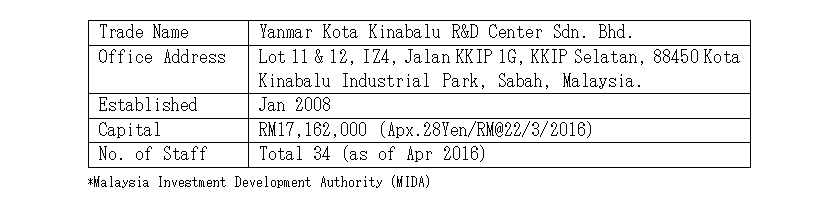

Yanmar Kota Kinabalu R&D Center (YKRC) in Malaysia was established on Jan 2008, located in the State of Sabah, Borneo Island of Malaysia. Yanmar currently has established three research institutes across the world, they are located in Japan, Malaysia and Italy. Maibara R&D Center in Maibara City, Shiga Prefecture of Japan was first established and followed by YKRC the second research institute. The establishment of YKRC is by invitation from Sabah State Chief Minister Datuk Seri Musa Haji Aman to Yanmar Co Ltd, to work together in effort to produce environmentally friendly machineries that could use bio-fuel produced from biomass. Thus, YKRC has granted R&D pioneer status (2007-2017) from MIDA. At the beginning, YKRC R&D activities mainly emphasize on the use of biofuels, but now YKRC has extended the R&D strength to study its production as well. YKRC has also played an important role in the group as the R&D center for the reliability and durability evaluation of Yanmar’s main products.

Table-1. Introduction to YKRC

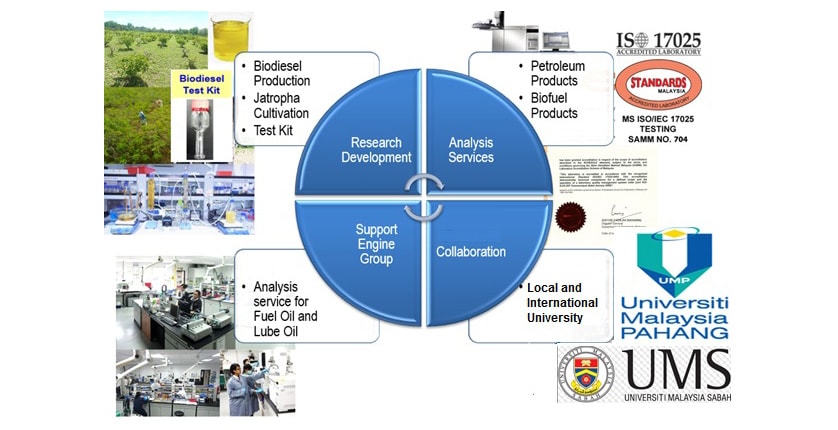

The research activities in YKRC are divided between two groups, Engine R&D group and Chemical R&D group. Engine R&D group is mainly performing research of durability and reliability for engine system. While Chemical R&D has been performing research on chemical analysis of biofuel and lubricating oil used which gives real time support to Engine R&D group. Besides the existing research activities, YKRC has also established R&D collaboration with local universities for examples University Malaysia Sabah (UMS) and University Malaysia Pahang (UMP).

2.Engine R&D Group

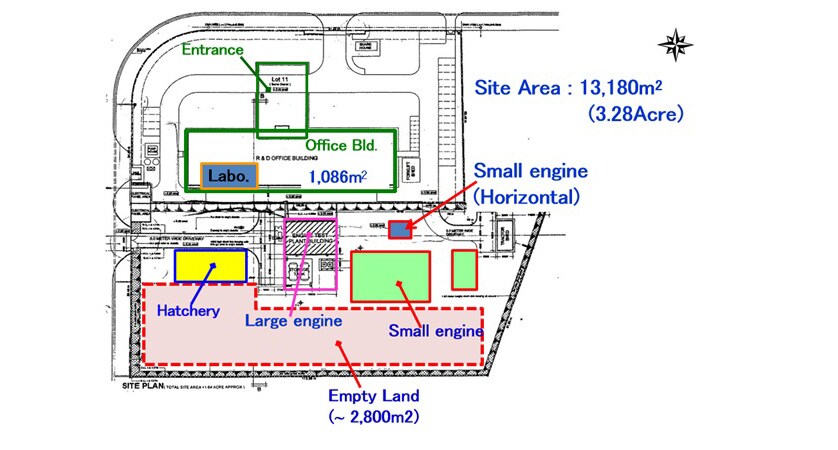

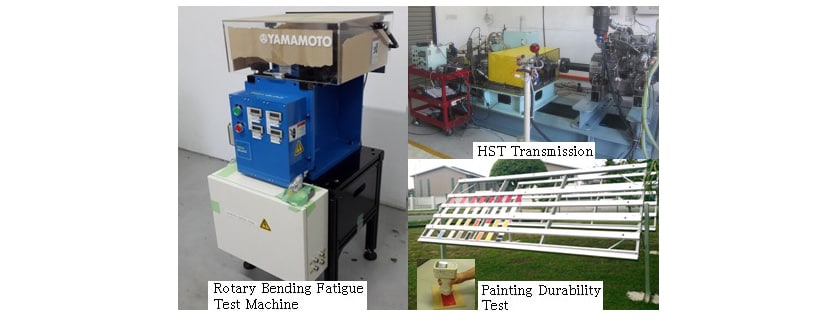

Reliability and durability evaluation of the engine has become one of the major activities of YKRC engine group. The 24 hours operation of engine evaluation activities is difficult in Japan while Malaysia having the stable climate throughout the year is a very suitable environment for endurance evaluation. The facilities in YKRC includes large engine test bench for large engine (marine auxiliary machinery, etc.), small scale test bench for small industrial diesel engines application (shown in Fig-3) and the durability and reliability testing facilities (shown in Fig-4).

2.1 Research Activity

The main activities of this facility are the evaluation of the reliability and durability of the large engines when using bio-fuel(SVO), NOX after-treatment equipment and also the electronic control fuel injection system (EUP). While for small engine test bench has the purpose of testing the emission of the engine which equipped with automatic driving control device and a measuring device that can respond to the latest emission regulations as well as evaluating component durability. Other reliability and durability facilities are painting evaluation and hydrostatic transmission by using bio-degradable oil. YKRC is able to do dimension measurement function of the parts before and after the test to determine parts endurance.

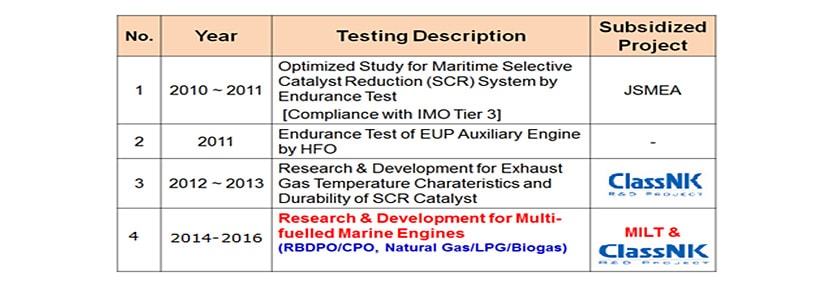

The YKRC engine research group had accomplished a number of research projects since 2010 (shown in Table-2). Most of these projects were subsidized by renowned institution or agency for industry collaboration research.

Table-2. Research activities of large engine

The recent activity of the engine research group is the R&D for multi-fueled marine engines which funded by MILT & ClassNK. The research had completed a 2000 hours of endurance test by using 100% refined, bleached deodorized palm oil (RBDPO) and the result was successful without major problem to critical engine components. This research is important in discovering the utilization of future alternative fuel as well as well as to support the reduction of CO2 emission into the environment. While for small engine research activity, includes VA/VE assessment of parts for TNV series as well as after treatment such as DOC & DPF durability evaluation. One of the research is the investigation about the effect of different cylinder liner temperature to fuel dilution of biofuel (SVO) running on horizontal engine. The result shows that the effect of the cylinder liner is comparatively low even though fuel dilution will increase when cylinder liner temperature decrease.

3.Chemical R&D Group

Chemical R & D group was originally created for chemically based activities such as chemical analysis, biofuel, and other sustainable solutions research. Chemical R & D group also involves in fuel and lubricating oil research from engine endurance and performance test. Besides that, Chemical R & D laboratory can also conduct research collaboration internationally and locally. YKRC laboratory now is an ISO 17025 certified laboratory, which can produce reliable test results as other worldwide recognized chemical laboratory such as SGS and Intertek.

3.1 Research Activity

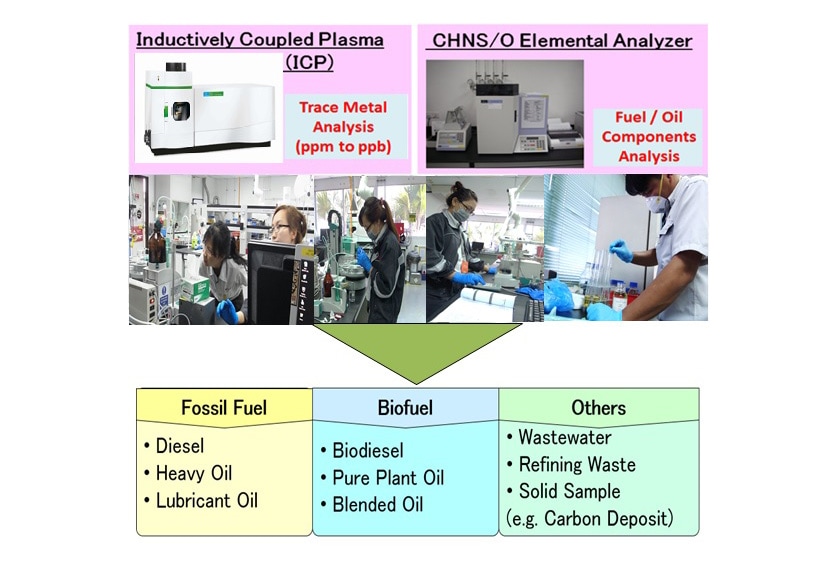

The laboratory of YKRC is fully equipped with various testing equipment and analyzers (shown in Fig-6), specializing in analysis of fuel and lubricating oil. These facilities have accelerated the laboratory analysis progress to accommodate the demands from customer without delay. Other than petroleum sample analysis from engine research, YKRC laboratory is also able to analyze different types of other samples such as waste water, feeds, soils and solid samples.

Besides analysis activities, YKRC chemical R&D group has developed their own bio-fuel test kit. Test kits will be able to provide immediate results in determining the usability and optimal change of fuel. YKRC has done research and development with respect to bio-fuel production. YKRC’s sustainable biofuel production focuses on Jatropha oil which does not compete with food supply chain. The research & development of biofuel has focused on its effectiveness of utilization. YKRC has rented a farm of about 1.1ha (shown in Fig-7). The purpose is to conduct the proliferation and varieties of optimal cultivation of Jatropha plants on farm site.

4.YKRC's Future Direction

The biofuel market has become part of the sustainable economic growth policy of the ASEAN countries, YKRC aim to act swiftly to capitalize on this opportunity, by turning into the technology hub of Yanmar Group in Southeast Asian region. In 2015, YKRC has revised the mission to – YKRC, as R&D center of ASEAN, concentrates local advanced technology, information network, and manpower, and proposes the business model, and then creates solutions and technologies to achieve the business model. This enhancement brings to the launching of planning function, the proposal of a midterm plan about YKRC and acceleration of application developing future research. This new mission is YKRC’s commitment to contribute to Yanmar brand statement – A Sustainable Future.

Author