Development Division

Agricultural Operations Business

YANMAR Technical Review

The Introduction of the Mini Tiller "YK-MR" Series "More simply, More easily"

Abstract

A mini tiller is the most popular machine which is used in a Japanese kitchen garden.

Recently, this machine that is simply and easily operated is used in a wide age bracket because of aging farming population and increasing of beginners who are interested in a kitchen garden.

We have developed a mini tiller with the stylish design which can be operated more easily and more simply.

This article describes the technologies of "YK-MR" series released last year.

1.Introduction

This is the 26th year since Yanmar commercialized its mini tiller. During this time, our models have evolved to be equipped as standard with a mechanism that allows ridging simply by turning a lever and extending a tail wheel when moving. These models include the “Uniaxial Forward-Reverse Rotation Tiller” series that minimizes dash-out while tilling and the “Opening-Closing Rotary Cover” series that enables piling soil work. The background to this is the aging farming population and increased interest in food safety and security, which has increased the interest of the people in general in agriculture.

We have paid close attention to the needs of customers through market research in various regions, resulting in the development of machines that can be used more simply, more easily and with greater sense of security.

2.Product Overview

2.1.External Appearance

2.2.Series Configuration

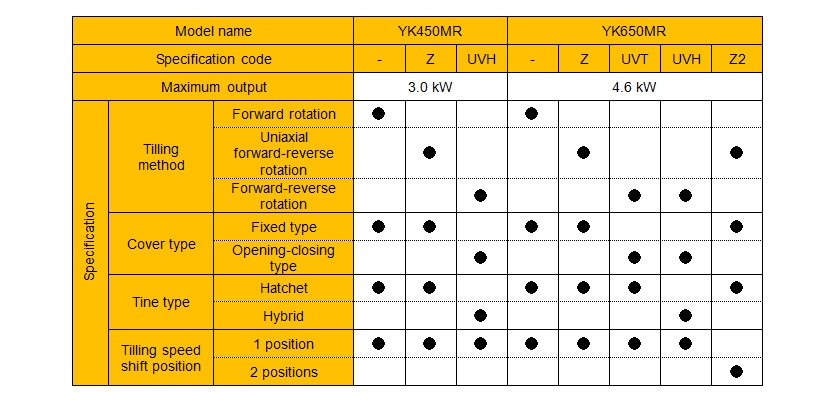

We performed module design because there was a need for specifications that finely meet the needs of customers in a wide range of ages, from beginners to expert users.

We provide a diverse range of specifications through different combinations of the engine, transmission, rotary cover and tiller tine. (Table 1)

Table 1. Specification List

3.Operability and Comfortability

3.1.Weight Balance

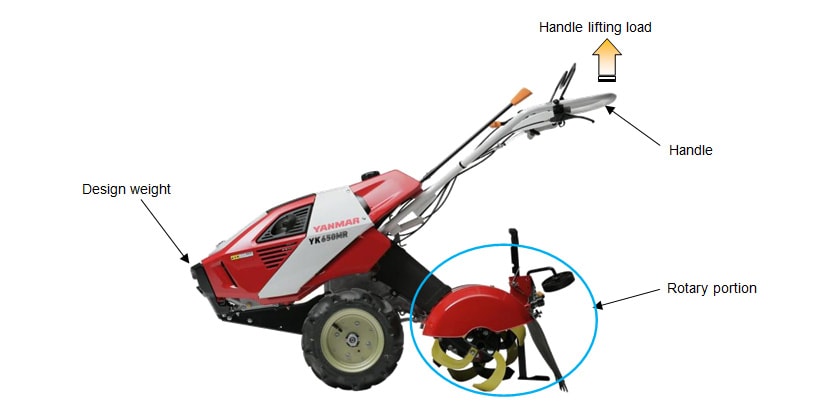

To ensure comfortable work, the machine must be secured stability when tilling and operability when turning. Weight balance is an important factor for achieving these performances. Increasing the weight on the rotary side improves the stability when tilling. On the other hand, because the handle is lifted up when turning, operability is improved by reducing the lifting load of the handle. Because the former results in rearward balance and the latter results in forward balance, we performed optimization in order to satisfy both sides. Also, these needed to be satisfied for each of diverse specifications by performing a module design as described in the previous section.

Because the structure has a large number of components to the rear of the tires, normally the balance tends to be rearward.

To resolve this problem, we made the handle and rotary portion as lightweight as possible, and adjusted the weight balance by mounting a design weight. As a result, we ensured stable tilling while reducing the lifting load of the handle by 15%.

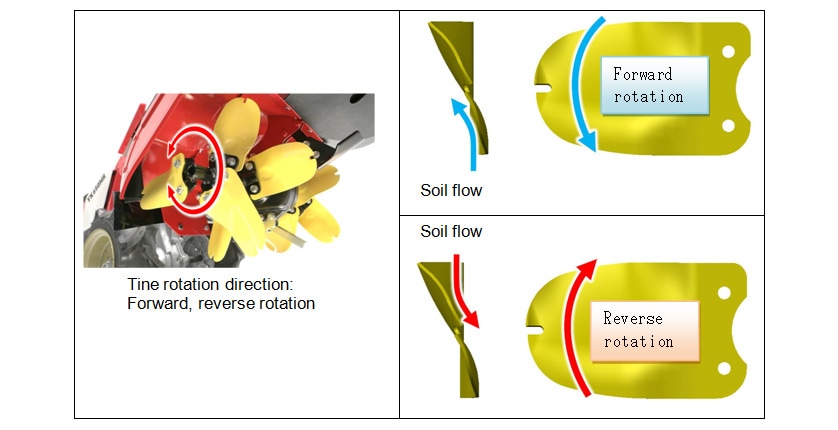

3.2.Hybrid Blade

When tilling and when making ridges by moving soil to the side, customers had to remove and replace the tine shaft, which resulted in installation errors or confusion about the reassembly method. To resolve this problem, we started the development with the goal of enabling “work to be changed without replacing the tine”. At first, we considered whether ridges could be made with a completely different method, but we realized that in order to make the required ridges, soil needed to be moved to the side. Because the rotation direction of the tine can be changed, we developed a new tine where the work changes according to the rotation direction. To satisfy the required performance during forward rotation and the required performance during reverse rotation with a single tine, we developed a twisted shape for the tine. The result was a hybrid tine that moves soil to the inside during forward rotation and to the outside during reverse rotation.

3.3.All-in-One

“Everything in one machine. Make everything easy.” We researched the different situations in which farmers work in fields. The works requiring the most labor are “tilling work” and “ridging work”. Also, the machine is moved every time from the barn to the field. Previously, these were performed by changing a separate attachment. The following describes the functions that have been equipped as standard to perform these functions.

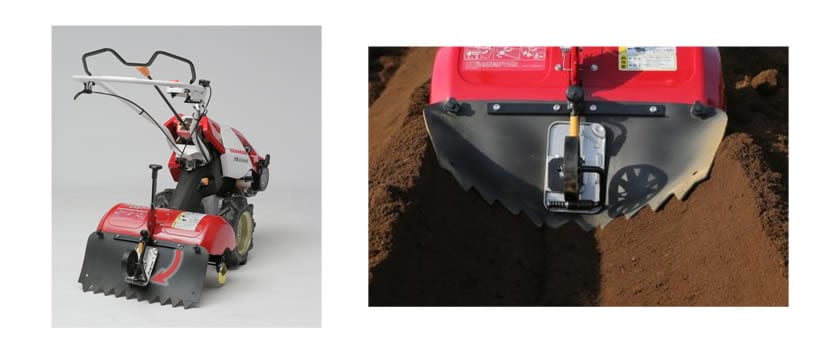

(1)Ridging function

The rubber mat used for soil leveling during tilling can now be used for ridging by operating a single lever. (Fig. 4, Fig. 5)

(2)Furrow width adjustment function

2 types can now be selected for both the furrow top width and the furrow bottom width, according to the field size or furrow application. Normal ridges, ridges with a narrow width, or furrows functioning as a passage for management work can be made. (Fig. 6.)

(3)Auxiliary wheel for movement

When moving machines, previously it was necessary to lift up the handle to float the rotary from the ground, or to equip a separate wheel attachment for moving. We have equipped as standard an auxiliary wheel with a one-touch operation for movement that is frequently occurred.

4.Tilling Depth

In terms of the tilling performance, crop growth is affected in particular by the tilling depth, harrowing performance and the turning over of soil performance. The performance of these factors is determined mainly by the shape of the tine and the rotary cover. We achieved the target tilling depth of 17 cm by maintaining the harrowing and turning over performance while carrying the soil within the rotary cover, and then discharging the adequate amount of soil from the rear of the rotary. (Fig. 8.)

5.Self-care Support

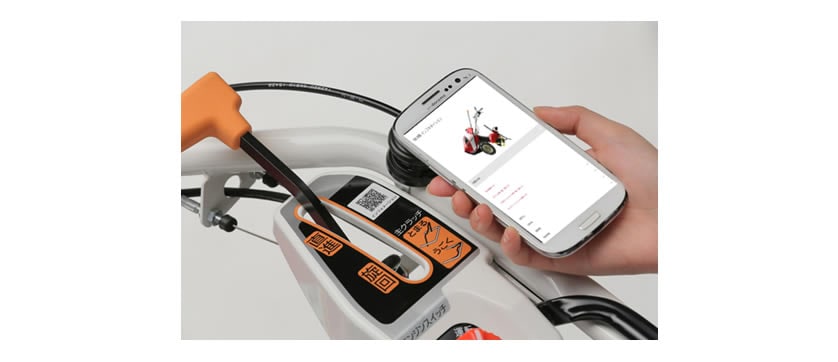

To maximize the lifecycle of the machine, one important point is to communicate operation methods in an easy-to-understand manner, so that even beginners can use the machine without making mistakes. Another is to have customers take care of their machines to enable the machines to be used for a long time. To resolve these problems, it is effective to use videos that show the operation and machine care methods. To do this, a QR code that starts up the video website is described on the machine, catalogs and operation manuals. (Fig. 9.)

6.Full Cover Design

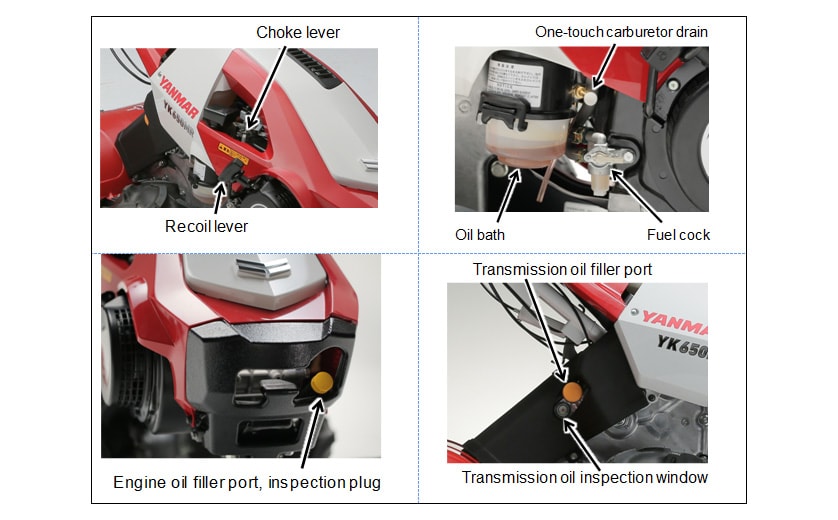

We adopted a stylish full cover design that realize friendliness and enables even beginners to operate the machine with a sense of security by hiding mechanical parts as much as possible. Another advantage of the full cover design is that only the required locations are visible, enabling customers to perform operations and daily inspections without being confused. (Fig. 10.)

7.Conclusion

We resolved each one of our customers' problems by our production, sales, service and development staff joined together as one team from the very beginning of development. Although some were quite difficult problems to overcome, we feel that these difficulties would pass away when we saw our customers using our machines happily in fields.

We will continue to evolve with new ideas in order to surely provide machines that help people become interested in “agriculture”.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Research & Development Management Division.

Author