Engineering & Development Dept.

YANMAR CONSTRUCTION EQUIPMENT CO., LTD.

YANMAR Technical Review

Introduction of Yanmar New Wheel Loader "V3-7" "V4-7" "V5-7"

Abstract

The wheel loaders are machines for the excavation and loading with a large bucket, and are popular in the world. The body structure is articulated and steering is operated by the hydraulic cylinder. Under the Japanese regulation they are classified into vehicle-based construction machinery. Large ones are used in civil engineering and quarry of sand and crushed stone loading, and small ones are used in snow removal work and livestock market.

In 2015, Yanmar released New V3-7, V4-7, V5-7 with the same off-road durability, working capability as the previous model. In developing, we had received many requests including the improvement of machine noise from the market. Accordingly new V3-7, V4-7 and V5-7 had been developed with the design concept "ultra-low-noise" and better maintainability, visibility and environmental features.

In this article, the techniques used to achieve ultra-low noise along with new features and associated technology.

1.Introduction

Articulated wheel loaders are wheeled construction machineries used for excavation and loading with a large bucket. The body structure is articulated ("Frames are jointed at pivot in the middle of body") that enables the machine to be steered by bending the body at the pivot using the action of a hydraulic cylinder. One of the feature of the articulated machine is no difference between the turning radius of the front and rear wheels, because the front and rear wheels follow the same path. Under Japanese regulations, they are classified as vehicle type construction machines. Large articulated wheel loaders are used for loading material such as sand or crushed rock in quarrying and other civil engineering applications, while smaller models are used for a wide range of purposes, particularly snow removal in snowfall regions, feeding out or manure removal in the livestock industry, or material transportation.

The Yanmar V3, V4, and V5 (see Fig. 1) have built up a reputation for good off-road performance, durability, and working capability and have been increasing sales since the first generation of small wheel loaders went on sale in 1983. The new generation of V3-7, V4-7, and V5-7 were launched on the market in 2015 to coincide with changes to exhaust emission regulations in Japan and foreign countries.

This model change has made the machines easier to use from a customer's perspective, with the inclusion of numerous improvements suggested for previous models while still maintaining the good off-road performance, durability, and working capability for which these previous models have developed a reputation. Achieving ultra-low noise levels, one of the most commonly requested improvements, was set as a development objective, with the result that the new wheel loaders have been designated as ultra-low-noise models by the Ministry of Land, Infrastructure and Transport.

This article describes the techniques used to achieve ultra-low noise along with the new features and associated technology.

2.Techniques for Achieving Ultra-Low Noise

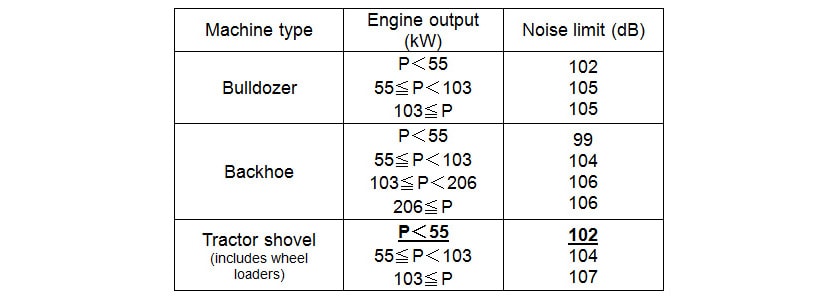

Since 1997, the Ministry of Land, Infrastructure and Transport has had a program for designating low-noise and low-vibration construction machinery based on regulations for this purpose that encourage the use of such machinery to protect living environments in the vicinity of construction sites and so that construction work proceeds smoothly. This includes the designation of construction machines as "ultra-low-noise" if they achieve noise levels 6 dB below the criteria stipulated in these regulations (see Table 1), in which case they are permitted to display a label testifying to this on the machine (see Fig. 2).

Under Japanese law, wheel loaders are classified as tractor shovels, as shown in Table 1, with the criteria for the "ultra-low-noise" designation being 96 dB or less in the case of machines with an engine output of 55 kW or less. The benefit for machines that satisfy these criteria is that they can be marketed as "ultra-low-noise".

Table 1. Noise Criteria for Construction Machinery(from Ministry of Land, Infrastructure and Transport Web Site)

Previous models have only been able to be labeled as "low-noise", having a machine outside noise of approximately 99 dB. In recent years use of "ultra-low-noise" machines has been requested as conditions for accessing local government subsidies or for bidding on government direct control projects. This has created an urgent need for ultra-low-noise wheel loaders.

Taking note of these factors, we set an ambitious development target of 95 dB (-4 dB) for its new models to provide a margin for the dispersion of volume production, and undertook preliminary testing and simulation to determine how to achieve this target in an efficient manner. It started by separating the acoustic sources in an early prototype and selected air intake and engine noise as targets for noise reduction, both of which are significant noise contributors.

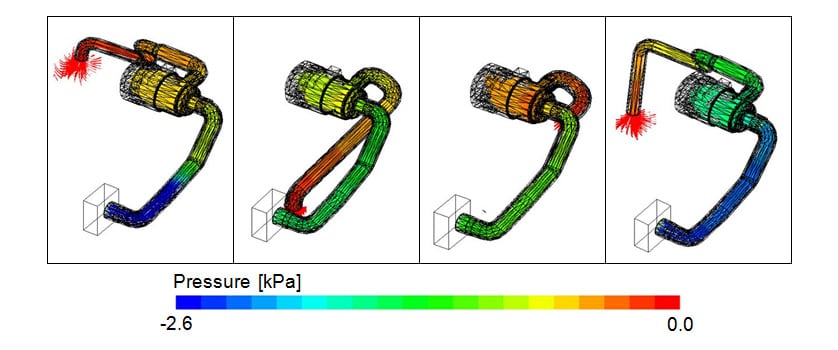

The greatest contribution to noise comes from the air intake. To reduce noise from this source, A prototype was built by determining the hose diameter, length, number of curves, and expansion ratio with use of computational fluid dynamics within a limit of > −2.9 kPa for the negative air intake pressure (see Fig. 3).

The second largest contribution to noise comes from the engine. To reduce noise from this source, noise insulation was fitted that has approximately 40% better noise absorption than the material used on previous models in the high-frequency range (800 to 4000 Hz) that has the greatest influence (see Fig. 4).

These measures were sufficient for commercially produced machines to easily clear the noise criteria of the Ministry of Land, Infrastructure and Transport. The heat balance, for which there is a trade off with noise, was also kept within Yanmar's own criteria.

3.Machine Features and Incorporated Technologies

This section describes the new features added on the V3-7, V4-7, and V5-7 in terms of environmental features, mainenability, safety, visibility, and cabin access.

3.1.Environmental Features

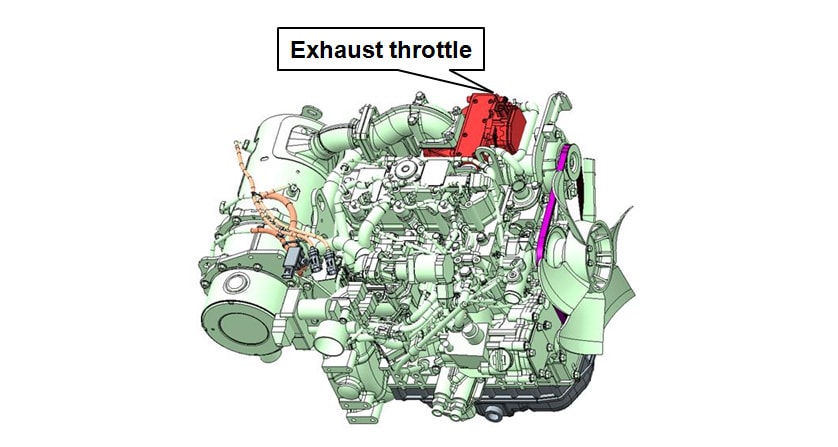

The engine is an electronically controlled common rail engine with a Yanmar diesel particulate filter (DPF) that complies with the 2014 emissions regulations for "non-road special motor vehicles" (see Fig. 5). It is the first engine for Yanmar Construction Equipment to have an exhaust throttle. Compared to earthmoving machinery such as hydraulic excavators that are operated with a fixed accelerator, it is common for small wheel loaders in which a foot accelerator is used to control traveling and working speed to frequently operate at low engine load, in which case the low temperature of the exhaust gas means that the DPF is not able to work with its underlying regeneration performance. To minimize this problem, the exhaust throttle is used to increase the exhaust temperature when the engine is operating at low load.

3.2.Maintenability

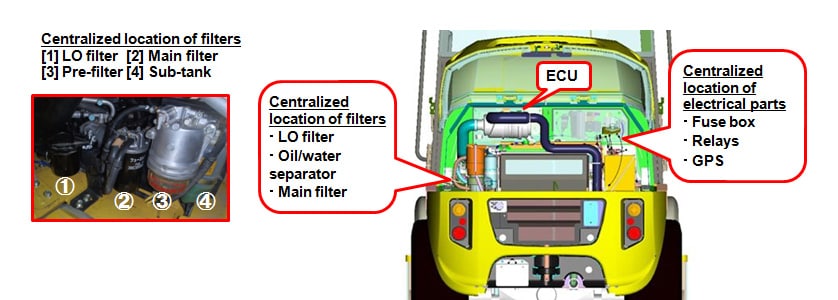

Along with a larger bonnet opening, maintenance on the new models was improved by centralizing the location of filters, fuses, relays, and other such components. In particular, the work for the LO filter replacement has been improved significantly by using hydraulic hoses to locate it in the bonnet opening (see Fig. 6). A battery cut switch has also been incorporated as a standard feature to prevent the battery going flat when the machine remains unused for a long period of time. This disconnects the earth circuit with a single action.

The new models also offer SmartAssist as an option. SmartAssist uses the GPS and communication unit to enable remote monitoring of the machine operation status and condition.

3.3.Safety

The cabin provides a high level of safety in compliance with the roll over protective structure (ROPS) and falling object protective structure (FOPS) international standards that respectively protect a seatbelt-wearing operator in the event of the machine tip over and from falling objects (see Fig. 7).

An external engine kill switch has been added to stop the engine by pressing it from outside the machine if needed in an emergency (see Fig. 8).

3.4.Visibility

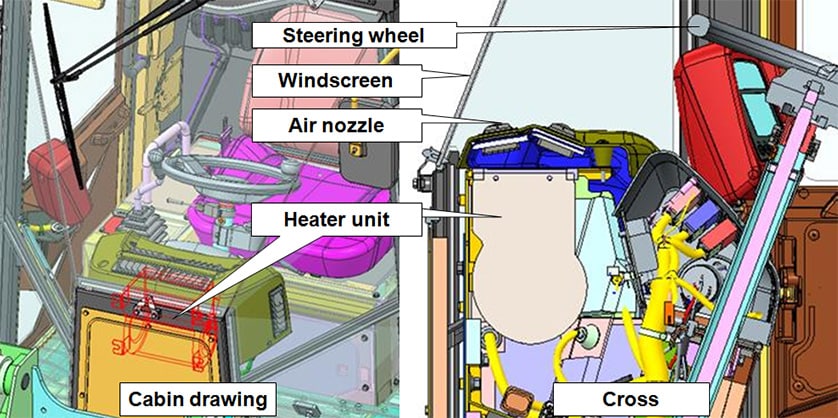

Approximately 80% of the wheel loaders manufactured annually by Yanmar Construction Equipment are cabin designs. These are mainly sold for snow removal in the Tohoku and Hokkaido regions of Japan. Snow removal is typically performed twice a day, in the early morning or evening. Along with cabin heating, this application also requires good windscreen defrosting to maintain visibility for the operator. The heater unit on previous models was located under the seat with warm air being carried to the windscreen nozzles through a hose. This led to problems with loss of air flow and warm air temperature. The heater unit on the new models is located between the cabin windscreen and steering wheel and designed so as to blow warm air directly onto the windscreen (see Fig. 9). This has achieved roughly 20 percent increase in defrosting performance relative to the previous models (see Fig. 10).

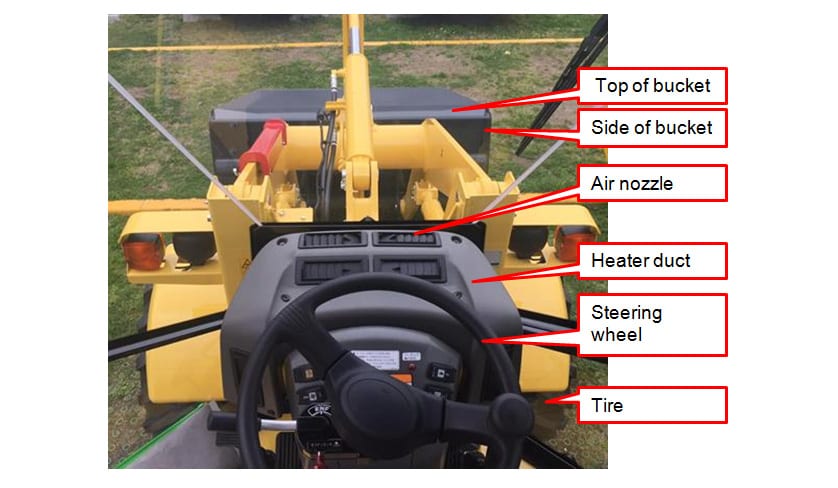

However, there was a concern that locating the heater unit in this way would impede the operator's forward visibility. The operator is most interested in being able to see the current height of the bucket, how much clearance it has from its surroundings, and where the tires are positioned (in other words, the ability to see the top and sides of the bucket and the tires). Accordingly, the air nozzles and the size and shape of the heat ducts were designed and located in order to provide sufficient defrosting performance, as described above, while still ensuring the operator is able to see the bucket (see Fig. 11).

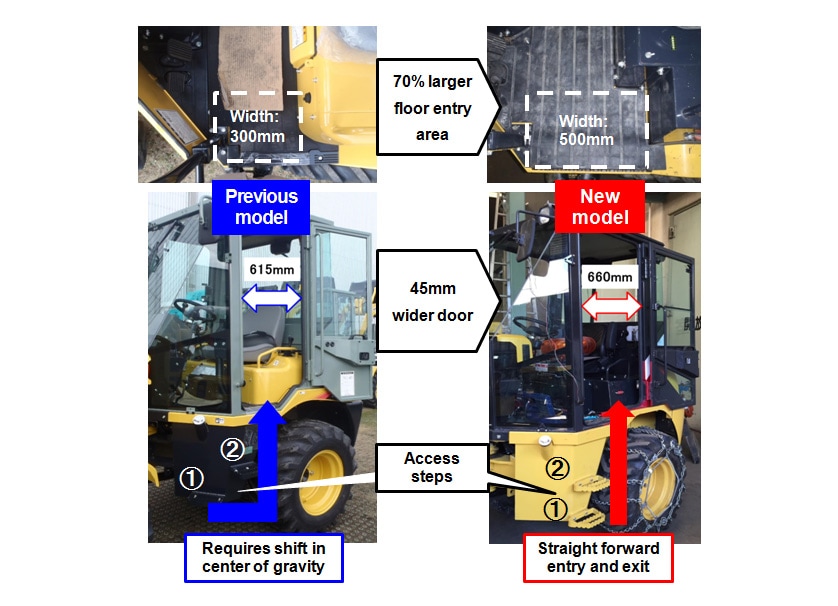

3.5.Cabin Access

The nature of articulated wheel loaders means that the operator seat is located above the engine bonnet consequently in a higher position. This makes the ease of getting in and out of the cabin an important consideration. To further improve cabin access relative to previous models, the access steps were aligned straight and the cabin door made 45mm wider on the new models. The area of the floor entrance was also made 70% larger to make it easier to turn around when getting in or out (see Fig. 12).

4.Conclusions

In achieving their objective of ultra-low noise, the new models faced numerous technical challenges, including the difficult task of reducing noise by 4 dB compared to previous models, and maintaining an acceptable trade-off between noise and heat balance. We set out to overcome these by conducting advance testing that involved preliminary tests and simulation using computational fluid dynamics, and followed a development schedule with a significant reduction in rework.

There were also numerous space constraints, including changes to the engine room layout to make space for a DPF and relocation of the heater unit, and difficulties were compounded by compliance with safety standards for "small-sized special motor vehicles", a requirement specific to wheel loaders.

The ultra-low noise and other improvements on the new models were incorporated to satisfy, as far as possible, the feedback and suggestions from the snow clearing and the livestock industries, both key markets for Yanmar wheel loaders, and have the potential to boost future sales.

We intend to continue undertaking product development in ways that satisfy customers through the ongoing collection of market feedback to develop products from a customer perspective.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Research & Development Management Division.

Author