E&D office

YANMAR CONSTRUCTION EQUIPMENT EUROPE S.A.S.

YANMAR Technical Review

YANMAR CONSTRUCTION EQUIPMENT EUROPE S.A.S.

1.Introduction

Yanmar Construction Equipment Europe (YCEE) is a mini excavators factory based at Saint-Dizier, in France.

In 1989, Yanmar and a Swiss company, Amman which is specialized in road construction equipment, made a joint venture. Amman-Yanmar is born, machines come from Japan and are finished and distributed in Europe from France.

In 2001, a first stage of expansion is done by installing a painting and an assembly line.

In 2007, through a second step, a mechanical welding workshop is implemented.

Finally, in 2010, Amman-Yanmar became YCEE.

| Trade Name | Yanmar Construction Equipment Europe S.A.S. |

|---|---|

| Office Address | Yanmar Construction Equipment Europe S.A.S. 25 rue de la Tambourine 52 100 Saint-Dizier, France |

| Employees | Around 350 |

2.Product Range

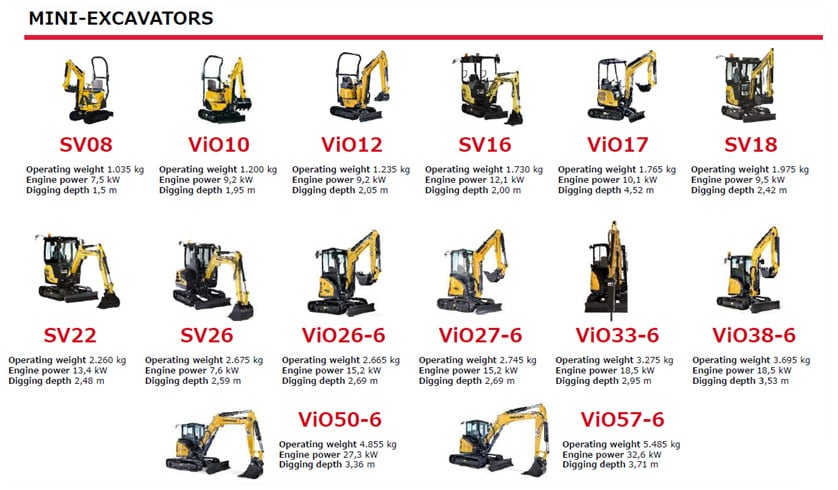

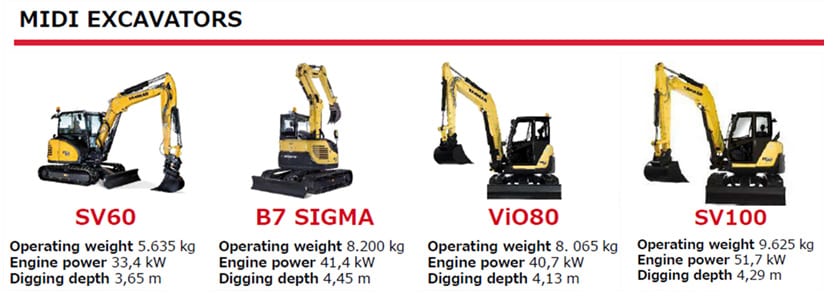

We have 18 models of excavators from 0.8 to 10tons, 4 models of carriers from 0.8 to 2.5tons and 2 models of wheel loaders.

Some models come from Japan and are finished at YCEE, these are CBU machines.

3.R&D Tasks and Role

(1) New Development

In Yanmar Construction Equipment machine range, there is 2 types of machines: zero tail swing (ViO) and conventional or semi-conventional machine with tail swing (SV).

SV machines are requested by European market so YCEE develops SV machines with YCE engineering support from Japan.

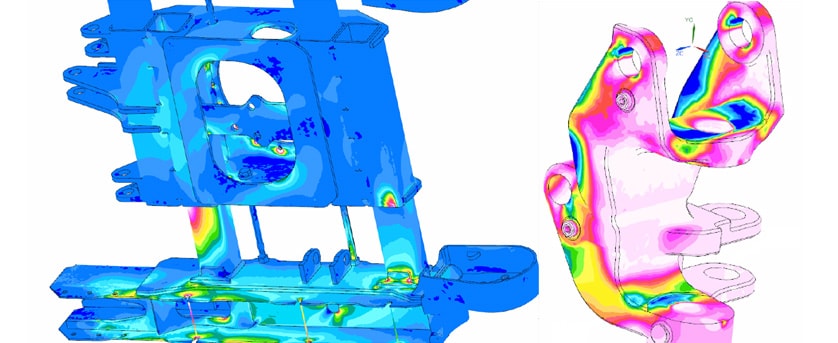

From marketing and sale specification, we choose engine and hydraulic system, we design structural parts and proceed to some FEM calculation by ourselves (some are done by Japan) and we design electric harnesses.

With test & validation department prototypes are built to make test to validate the performance and the strength of the machine.

(2) Production transfer

To share development and to speed up renewal of machines range, some products are developed and produced in Japan first, then production is transferred in France.

E&D dep. takes care of modification to do to match with YCEE industrial process and suppliers process for localized parts.

(3) Development for specific European request

As every market, Europe has its own specification and needs so, at YCEE, we develop the specific options for CBU or production transfer machines. We also develop specific options for our big customer (meanly rental companies).

It concerns every field of knowledge: for example, electric matter for antitheft devices, hydraulic for special auxiliary circuit or mechanical for central greasing system.

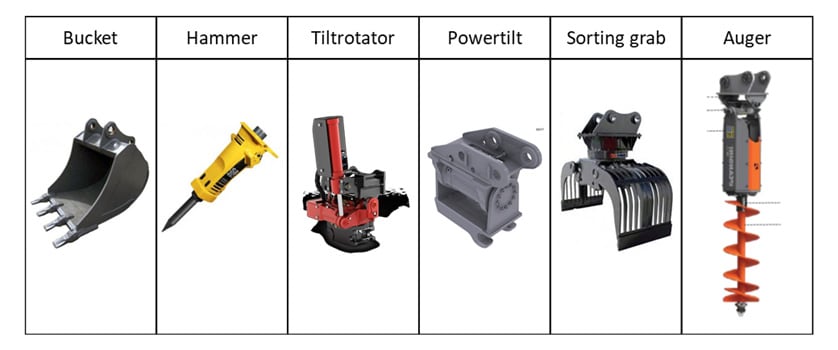

YCEE proposed also a full range of accessories as bucket, hammer, tiltrotator, powertilt, sorting grab, auger. E&D department validate each accessory to ensure to customer to work safely by checking machine stability and lifting capacity.

(4) Serial life job

One team is dedicated to machine serial life improvement, there is various job as update of machines based on market feedback, cost savings or assembly and quality improvement.

4.YCEE's Future

We want to increase our skills to be more performant, efficient and autonomous in development to lead European business by ourselves.

For the future, we hope to have more and more collaboration between the 3 branches of Yanmar Construction E&D office (Germany, Japan and France), to have global understanding of markets.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Research & Development Management Division.

Author