Engine Development Division

Industrial Power Products Management Division

Power Solution Business

YANMAR Technical Review

4LV Series of Next-Generation Marine Engines: Outperforms Existing Models on Acceleration and Noise Level

Abstract

Yanmar's new 4LV series of marine diesel engines were released in 2017. The new engines are a marinized version of an automotive engine and incorporate proprietary control logic for marine propulsion. The adoption of optimized combustion technologies and a common rail fuel injection system have enabled the engines to comply with stringent exhaust emission regulations while also satisfying customer requirements for acceleration and for low noise and vibration. The electronic control system allows easy engine installation, communication with onboard navigation devices, and connection to a joystick maneuvering system. Yanmar believes the new engines will delight customers. This article describes the new technologies used in the 4LV series engines.

1. Introduction

Small diesel engines are a core product of Yanmar and marine engines form a part of this product range. These are particularly well known in Europe and America where for many people the name Yanmar is synonymous with marine engines. They include diesel engines for sailboats (boats that are primarily wind powered) where Yanmar has the leading share of the international market. In this application, the engines are used for in-harbor maneuvering and to provide an onboard electric power supply. Diesel engines offer excellent reliability and durability for boat propulsion, making them a common choice for inboard engines (engines installed inside the boat) where they are continuously exposed to a marine environment.

Boats that use small diesel engines come in a diverse variety of forms depending upon the purpose of use, include sailboats, fishing boats, cruisers, and rescue boats. For boats such as fishing boats and cruisers in particular, there is a large market for inboard engines in the 110 kW to 180 kW range, making engines in this power range an extremely important sector. Within the Yanmar product range, this power range has been covered by the 4LH and 4/6BY series, with the 4LH series being used in light-duty commercial applications and the 4/6BY series in pleasure boat. In other words, the same power range has been covered by two different engine series with different specifications. In response, Yanmar has developed the 4LV series as a new-generation engine suitable for both light-duty commercial and pleasure use as well as for large sailboats, another category with strong market demand.

2. Product Overview

The 4LV series are marine diesel engines that first went on sale in 2017. Having been newly developed to replace the 4LH and 4/6BY series, they retain the same external dimensions to facilitate engine replacement and feature excellent acceleration and noise level performance.

Although based on an automotive engine, the 4LV series have been modified for marine use to optimize them for this completely different application. Yanmar has also drawn on the experience and know-how it has built up as a manufacturer of marine engines to ensure reliability despite the engines being installed in the vicinity of seawater. Yanmar also succeeded in shortening the development period by making as much use as possible of analytical techniques from the preliminary development stages.

In order to comply with the US Environmental Protection Agency (EPA) Tier 3 standards and other international exhaust emission regulations, the engines use a fully electronic common rail system for fuel injection to achieve optimal combustion matching.

The 4LV series product range includes five inboard and five sterndrive (inboard-outboard) engines, the 4LV150(Z) (110 kW), 4LV170(Z) (125 kW), 4LV195 (143 kW), 4LV230 (169 kW), and 4LV250(Z) (184 kW). All are fitted with a turbocharger. Table 1 list the main specifications for the series.

Table 1 Main Specifications of 4LV Series

| Engine | 4LV150(Z) | 4LV170(Z) | 4LV195(Z) | 4LV230(Z) | 4LV250(Z) |

|---|---|---|---|---|---|

| Maximum power (kW) | 110 | 125 | 143 | 169 | 184 |

| Maximum speed (min-1) | 3500 | 3800 | |||

| Displacement (L) | 2.755 (4 cylinders) | ||||

| Bore & stroke (mm) | 92×103.6 | ||||

3. Technologies Used and Value Added

3.1. Product Enhancements

3.1.1. Acceleration

Acceleration is an important factor for providing boat users with comfortable propulsion.

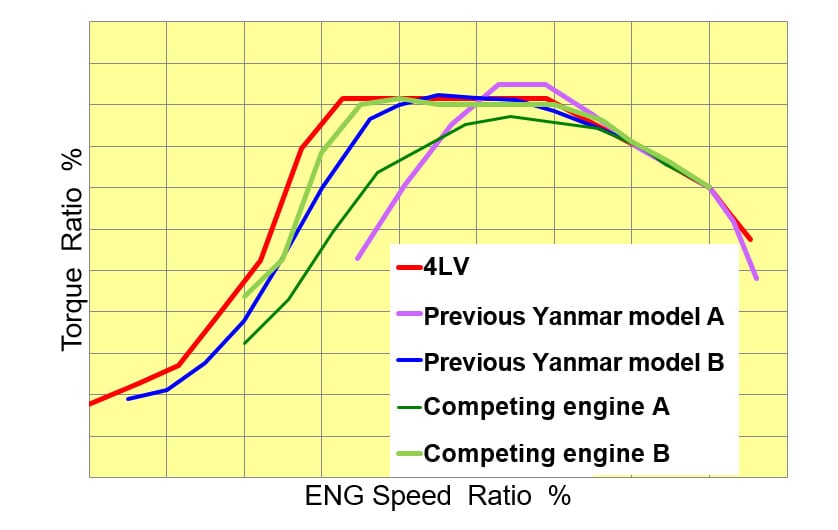

A key influence on acceleration is the amount of torque available at low engine speeds. In this regard, the 4LV series outperforms the previous models and other competing engines in the same class, providing smoother acceleration (see Fig. 1). Through optimal combustion matching, the engines are designed for user comfort while still satisfying stringent European and American environmental regulations.

3.1.2. Low Noise Performance

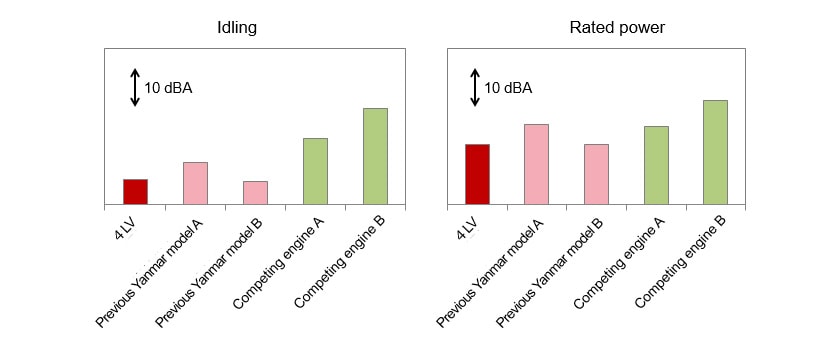

While small boats come in a variety of forms, the 4LV series is primarily targeted at pleasure boat, meaning that achieving low engine noise is an extremely important consideration. The limited space available inside boats means that the engine room is located adjacent to passenger space, with the layout of some boats being such that it is separated by only a single bulkhead from living and sleeping areas. Achieving a low level of noise is essential to providing a pleasant onboard environment.

The 4LV series uses a common rail system with electronic control of the timing and frequency of fuel injection to optimize combustion. In terms of the engine's design, the internal features that enable it to achieve a lower level of engine noise than competing engines include the use of a second order balancer and chain drive for the cam and fuel pump. Externally, it also uses marinized components that include redesigned shapes for the top cover and belt cover (see Fig. 2). As the low noise level is something that can only really be experienced when on board , users are kindly requested to try it for themselves.

3.1.3. High Level of Environmental Performance

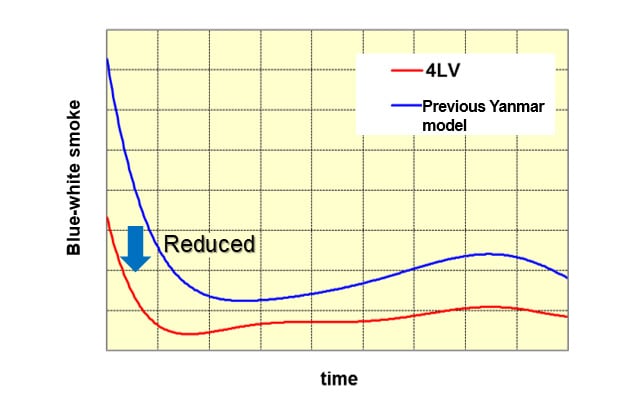

Along with the noise level, among the things that people notice when first going out on a boat are the smell of exhaust gases, smoke from the exhaust pipe, and floating oil. The first two of these can make users feel unwell, while the presence of floating oil in large amounts is a source of pollution at marinas. The main causes of these phenomena are blue-white smoke and unburned components in the exhaust.

The 4LV series uses optimal combustion matching to improve environmental performance by reducing blue-white smoke to even lower levels than produced by the previous engine models, which also used a common rail system (see Fig. 3).

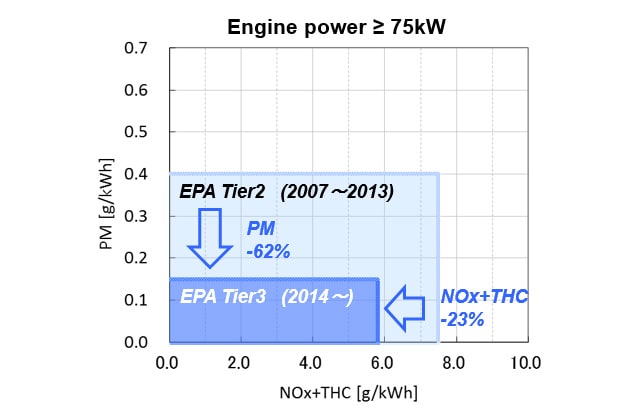

Two of the main exhaust emission regulations for marine diesel engines are the EPA regulations in America and the Recreational Craft Directive (RCD) in Europe. While these regulations have been made more stringent, with EPA marine tier 3 introduced in 2014 and RCD stage 2 in 2016 (see Fig. 4), the 4LV series has been certified under both. The new engines also emit significantly less black smoke than the previous models.

3.1.4. Yanmar Brand Enhancement

Attention to the engine usually hidden away in the engine room is requested.

A feature of 4LV series engines intended to provide visual appeal is their covers. The three main covers used on the 4LV series are the top cover, the belt cover, and the ECU cover. Their primary purpose is to protect the internal parts and prevent injury. While steel plate has commonly been used for marine engine covers in the past, the covers on the 4LV series have the added benefit of a visually attractive design. The top cover in particular not only serves as the "face" of the engine but also as a platform to stand on during maintenance. To ensure that it would be strong enough as well as looking attractive, its shape was only finalized after considerable detailed discussion between the designers and suppliers (see Fig. 5).

The design follows that of the 6LY400/440 engine released in 2015 (see Fig. 6), and Yanmar intends to enhance its brand by continuing to use this design in future marine diesel engines.

3.2. Maintaining Ease of Engine Installation

As a feature of the marine market, including pleasure boat, is that hulls have a life measured in decades, there are therefore frequent occasions on which the engines are replaced. For the 4LV series to be suitable for use as a replacement engine, it needs to be easy to install. Particular consideration was given in the design of the 4LV series to the following three points, which are important for achieving ease of installation.

3.2.1. Ease of Engine Replacement

- Avoid need to modify engine room

- To avoid any need for engine room modification, the 4LV series engines were designed to be similar in size to previous Yanmar models and competing engines in the same class. The installation width of the engine mounting feet is also the same as that of previous models so as to avoid the need to modify the engine beds.

- Allow replacement into boats with mechanical control system

- Although use of electronic control for the engine and marine gear has increased in recent years, many boats still use mechanical controls.

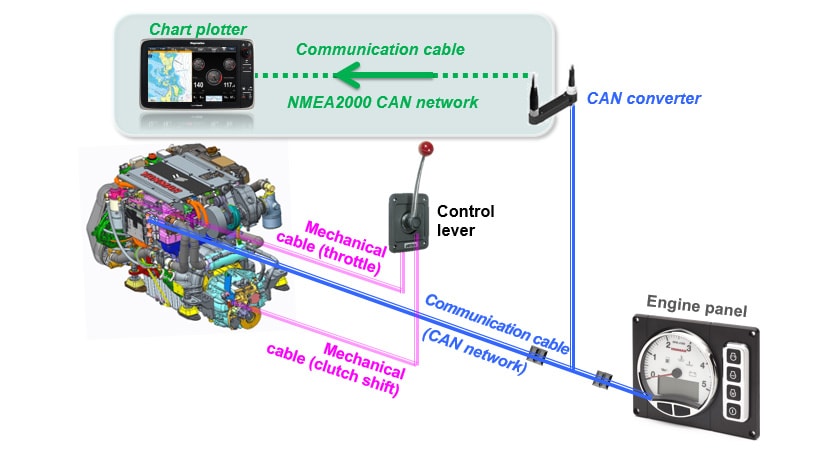

To make it possible to continue using the existing mechanical control levers, the 4LV series is also available with mechanical rather than electronic control. Engines with mechanical control work by using potentiometers mounted on the engine to convert mechanical control lever inputs to an electrical signal. This means that the cables used by the exiting mechanical control system can be connected to the 4LV series without further modification (see Fig. 7).

3.2.2. Connectivity (Single Connection to Onboard Equipment)

Boats are equipped with a wide variety of devices to suit different user preferences, such as chart plotters that record its course on a map. As this includes devices that require information such as fuel consumption and engine speed, the difficulty of obtaining this information from conventional mechanically controlled engine has been inconveniences for users. Accordingly, to improve compatibility with these onboard devices, the 4LV series have been designed to output the required digital data directly from the engine. This means that these devices can be connected to the engine simply by plugging them into the connectors on the wire harness, reducing the work required for connecting and exchanging information between the engine and onboard devices much simpler (see Fig. 7).

3.2.3. Ease of Installation and Maintenance

In response to the needs of boatyard and field service staff, the 4LV series has been made easier to install and maintain (see Table 2).

Table 2 Improvements in Ease of Installation and Maintenance

| Objective | Improvements |

|---|---|

| Shorter installation time Prevention of errors |

Labels added to indicate location of cooling water outlet, fuel inlet, and other which connect to the coupler on the hull |

| Shorter maintenance time Prevention of errors |

Label added to indicate serpentine belt layout |

| Injury prevention | Protective cap fitted over sharply pointed hose clips |

3.3. Compatibility with Electronic Control Systems

3.3.1. VC10

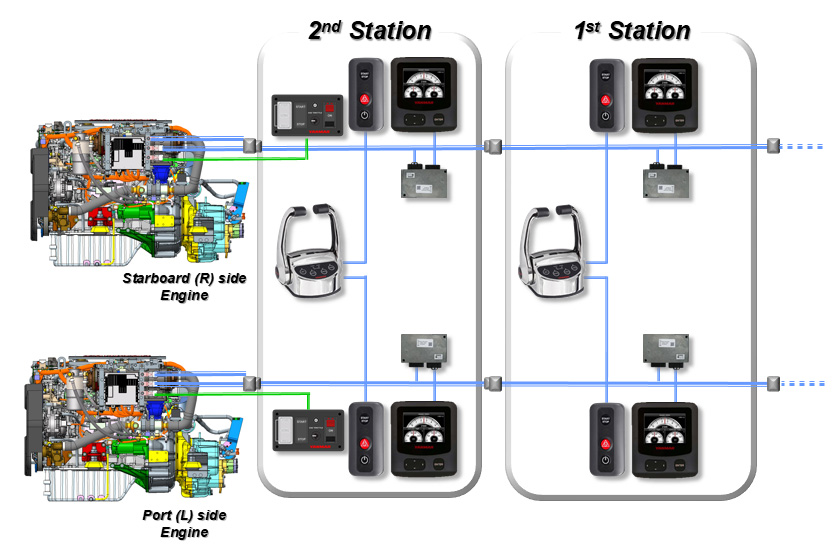

The 4LV series can work with Yanmar's proprietary VC10 electronic engine control system. VC10 includes a capability for synchronizing engine speeds when multiple engines are installed. As VC10 controls the engine by using electric communication (CAN signal), it can be connected with an easily installed network cables and thereby it does not require components such as the throttle cables used by mechanical control that would otherwise impose major constraints on installation. This provides greater freedom in boat design, by allowing the helm to be located wherever the designer wants, for example (see Fig. 8).

3.3.2. JC10 Joystick Control System

As a degree of skill is required to operate a boat in constricted waters, such as when mooring or maneuvering in narrow channels or marinas, there is a demand for systems that are easy to operate.

Together with VC10, Yanmar's proprietary JC10 electronic steering control system for steering and position holding enables even inexperienced operators to steer the boat with confidence, including a function for holding constant position and joystick-operated capabilities for 360° rotating in a confined space or maneuvering the boat to the left or right/forward or backward while keeping it on a steady heading. Compatibility with JC10 will be added in future 4LV series engines.

Fig. 9 shows how a boat with two Yanmar sterndrives is operated using JC10. The required boat motion is achieved by controlling the port and starboard engine speeds together with the sterndrive steering angles.

3.4. Responses to Market Demands

As described above, small diesel engines are used in a wide variety of boats whose users have different requirements. The 4LV series offers a variety of options to satisfy diverse market demands Table 3 lists these options.

Table 3 4LV Series Options

| 4LV Options |

|---|

| Variety of propulsion system |

| Exhaust mixing |

| Two-wire system |

| Secondly alternator |

| Front PTO |

| SOLAS (rescue boat engine) |

| Ability to draw off coolant for heating |

| VC10-compatible control panel |

4. Conclusions

As described in this article, the newly developed 4LV series realizes top-class performance compared to competing engines of the same class, especially with regard to acceleration and low noise. Yanmar has also taken note of the requirements of boatyard and field service staff by making the 4LV series easier to install and maintain. Also planned is the ability to use Yanmar's JC10 joystick control system that makes boats easy for users to operate.

In the future, Yanmar intends to continue striving to provide products that delight its customers.

-IMPORTANT-

The original technical report is written in Japanese.

This document was translated by Research & Development Management Division.

Author

Engine Development Division

Industrial Power Products Management Division

Power Solution Business