High-speed Engine Engineering Division

Development Division

YANMAR POWER SOLUTIONS CO., LTD.

YANMAR Technical Review

GY175 Next-Generation High-Speed V-Type Diesel Engine

Development of Electronically Controlled Engine for Stationary Electricity Generation

Abstract

The 12GY175L is an electronically controlled, high-speed V-type diesel engine developed primarily for the overseas land power generation market. In the large land power generation market, demand for generators as backup power sources for data centers has rapidly increased in recent years due to the spread of digital transformation, AI, and cloud services. Emergency generators for data centers require not only compactness and high output, a requirement for land power generators, but also the ability to instantly switch over to backup power.

The GY175L features a common rail fuel injection system for optimal fuel injection control, and four small turbochargers to meet all requirements: “performance required for emergency power generator,” “high transient performance required by customers,” and “environmental regulations in various countries.”

This article introduces the engine overview, applied technologies, and performance of this new, next-generation, high-speed V-type engine for land use.

1. Introduction

Large stationary generators are used both for routine power supply and as emergency backups that can supply power to keep equipment running when electric power is lost due to a disaster or other outage at a factory or at a facility such as a hospital. As the rising of electricity demand, the trend in these generators over recent years has been toward larger capacities. Because space constraints still apply, however, this is driving rising customer demand for generators and the engines that drive them to be more compact and to have higher power ratio. Meanwhile, the spread of digital transformation (DX), artificial intelligence (AI), and cloud services has brought a rapid rise in the demand for backup power supplies at data centers. In this application, the requirement is not only for compact generators with high output, but also for high transient performance.

When generators are installed at urban sites, they also need to comply with the rules on exhaust emissions that have been established in Japan and elsewhere to minimize atmospheric pollution and the risk of damage to human health.

To satisfy these market demands, Yanmar has developed its 12GY175L V-type diesel engine with electronic control that is the first of our large high-speed engines to feature a common rail system.

This article describes the technologies used in the new 12GY175L engine.

2. Product Concept (Performance Requirements for Data Center Use)

The engine was developed based on the following product concept, which was formulated to ensure that it would satisfy the requirements for use as a backup power supply at data centers.

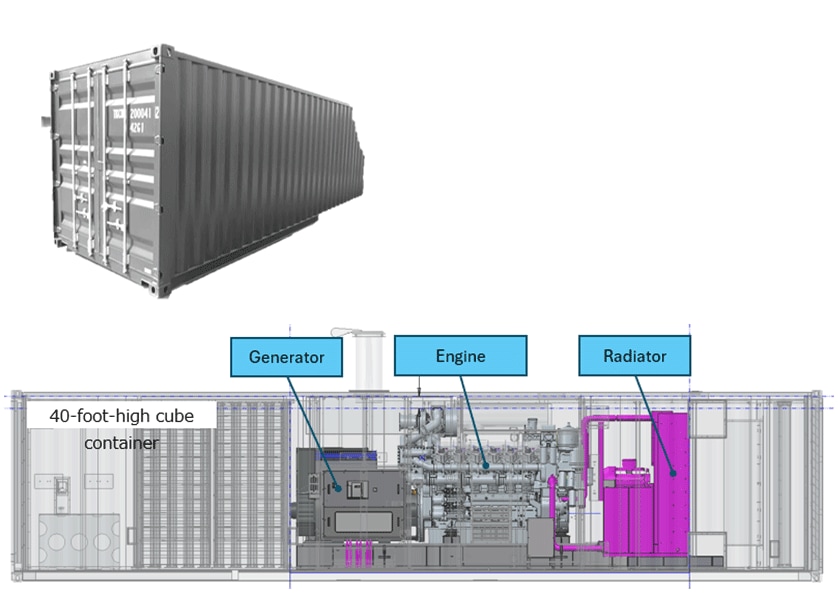

・Compact design with high output

To allow for easy delivery and installation in overseas markets, the generator system needs to be small enough to fit in a container. Given that the system components include not only the engine, but also other large equipment such as the generator and radiator, the design must be compact enough to fit all of these into a 40-foot high-cube container while also having sufficient power to meet demanding power supply requirements.

・Rapid response

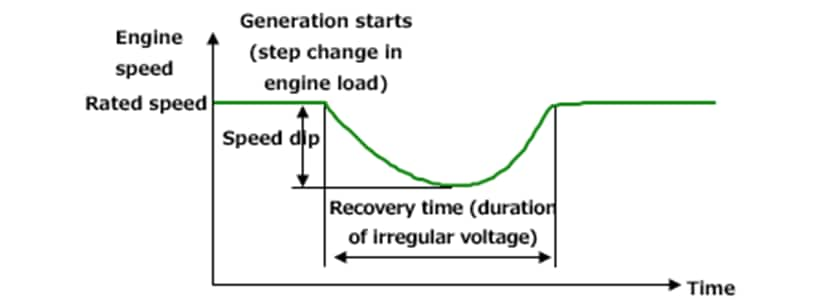

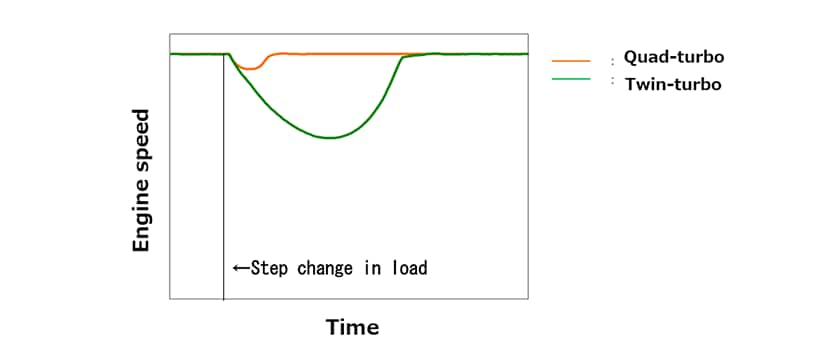

The system needs the ability to instantly switch over to supplying backup power to prevent service interruptions or data loss when the grid power supply is cut off by a disaster or other outage. When operating, it must also be able to maintain a reliable supply of large amounts of power. The rapid increase in the load from the generator that occurs when generation starts (when the engine comes under load) causes a temporary dip in engine speed. To ensure an uninterrupted supply of electric power to data center systems when switching over to the backup power supply, it is vital to make this dip as small as possible. For diesel generators, ISO 8528-5 standard defines performance classes G1 through G3 based on engine speed transients (changes in engine speed as a proportion of rated speed) and settling time (time for the speed to return to rated speed). Generators used at data centers need to satisfy the most stringent G3 class.

・Environmental performance

The engine also needs to minimize the emission of black or blue-white smoke due to poor combustion at startup in order to comply with national environmental regulations (in Japan, the Air Pollution Control Act and ordinances) and to avoid causing damage to health or prompting compensation claims from neighbors when installed at an urban site.

3. Overview of Engine

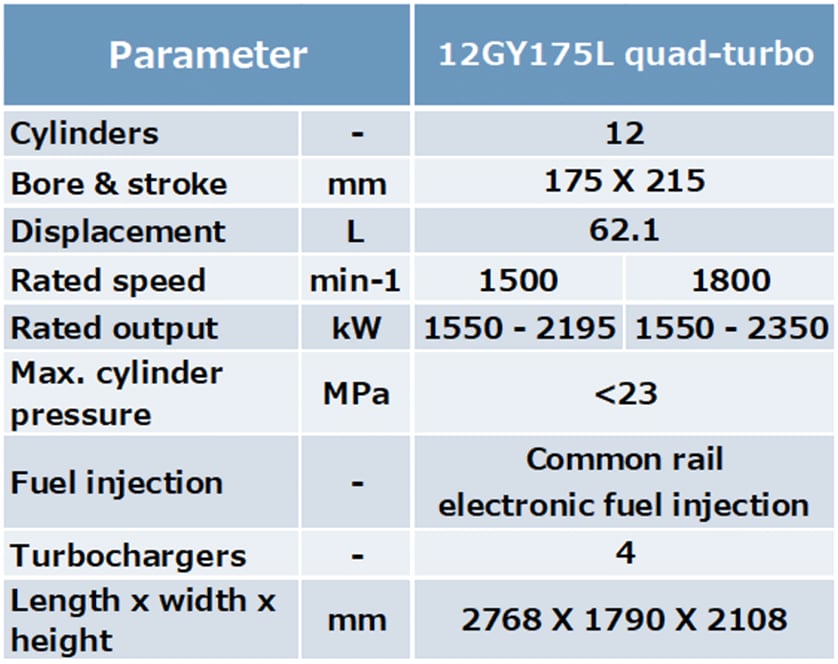

Table 1 lists specifications for the new 12GY175L engine.

The number of cylinders has been increased while keeping the height of the engine to a minimum by orienting them in a V configuration and the output per cylinder has been increased to combine high power with compact size.

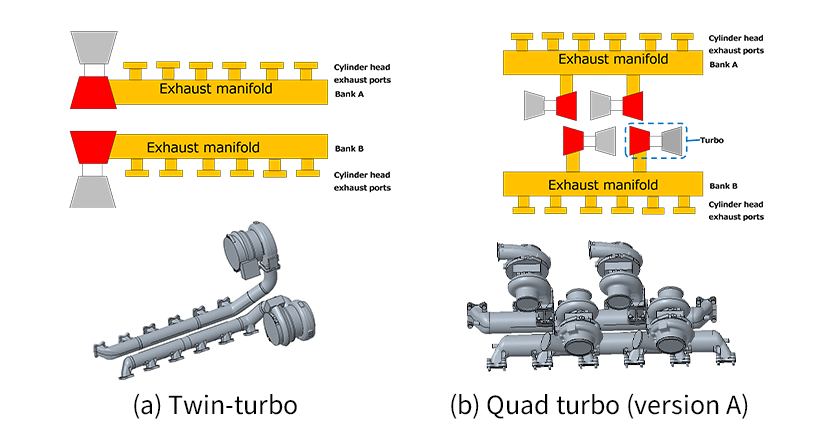

To achieve a fast response, the engine is equipped with a quad-turbo system with four small turbochargers that respond more rapidly to load fluctuations than a large turbocharger would.

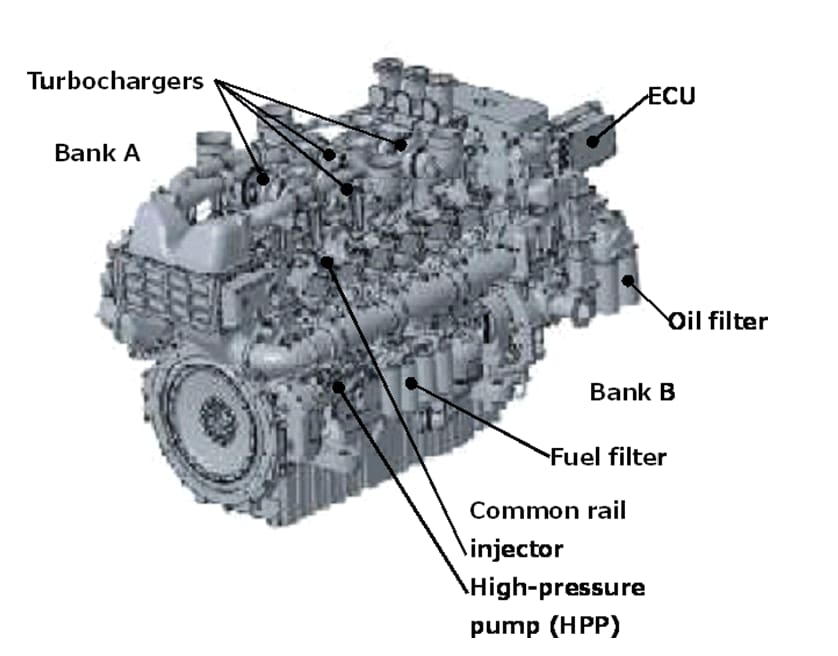

Figure 3 shows the engine.

The 12GY175L is electronically controlled and is the first large Yanmar diesel engine to feature a common rail system. Two turbochargers are located on top of each cylinder bank.

To enable all maintenance to be performed from the same side of the engine, the oil filter, fuel filter, and engine control unit (ECU) are all mounted on the same cylinder bank.

4. Engine Technologies and Performance

4.1. Optimization of Engine Component Design

To achieve its higher power, the 12GY175L operates with higher mechanical load (pressure, temperature) than previous engines.

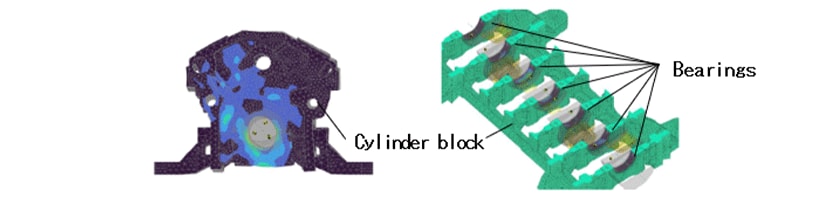

To ensure that the engine design can cope with this higher cylinder pressure, the main components were designed with the help of computer-aided engineering (CAE) analysis.

Analysis was used to optimize the detailed internal geometry of the cylinder block, ladder frame, and other main components to ensure a compact design and avoid having to increase their external dimensions. The lubrication of sliding parts is also important for ensuring that the high combustion energy is converted efficiently into rotational motion. Here, too, the design was optimized by performing an analysis of the oil film in the crank bearings to ensure that the required film thickness is maintained. For the surface layer of the bearing metal, meanwhile, a polymer was selected that provides effective performance in terms of embedding foreign matter and initial running-in with the crankshaft.

4.2. Reduction of Thermal Load

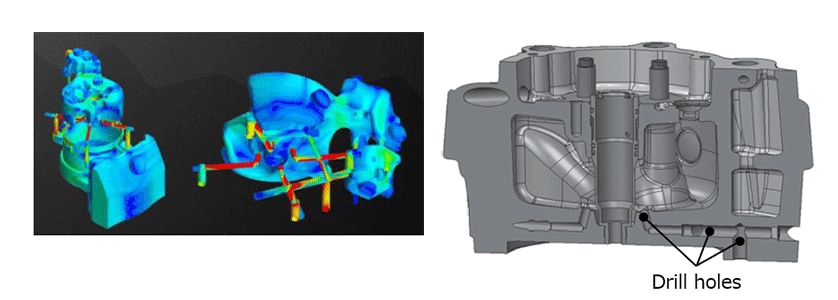

Having a higher engine output means exposing the parts around the combustion chamber to more heat.

Cooling design is particularly important for the cylinder heads as a lot of heat is transferred to these from the combustion chambers. To reduce the thermal load on the cylinder heads, the development used analysis of water flow in the vicinity of the combustion chamber and heat transfer simulation to optimize the design for cooling performance. The results of this analysis indicated that drill hole cooling would improve the cooling performance for locations such as between the exhaust valves and around the combustion chamber that are particularly prone to temperature rise. While machining long and narrow holes is not easy, reliable cooling was achieved through improvements to the location and flow rate performance of the cooling water channels.

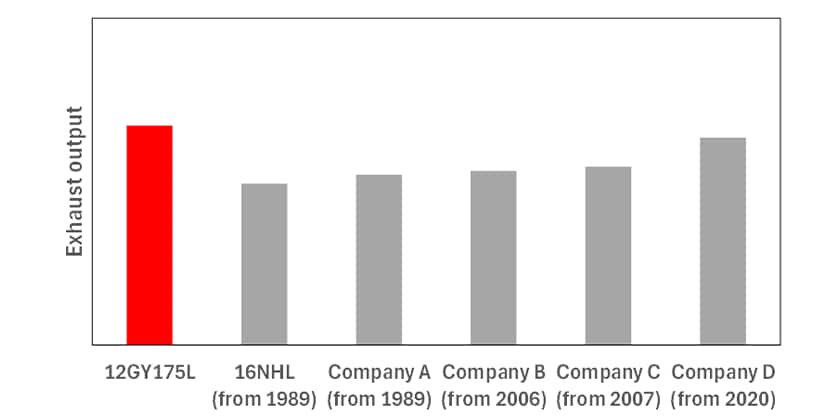

Through these measures, and by drawing on accumulated expertise in large engines and making use of CAE, Yanmar succeeded in equipping the 12GY175L with high output and making it compact enough for the entire generation system, including ancillary equipment, to fit into a 40-foot container while also maintaining reliability and durability. Figure 6 compares the output density of the 12GY175L with that of Yanmar’s existing diesel engine in this output range (the 16NHL) and other competing engines. While the figure shows output density rising with the improved performance of more recently released engine models, it is the 12GY175L that has the highest output density of all.

4.3. Optimization of Intake and Exhaust Layout

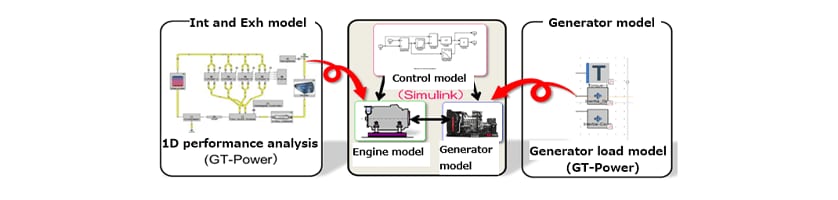

Data center generators are required to supply large amounts of power from the moment they start generation, with the ability to handle step changes in load of 50% or more (increase in load as a proportion of rated output) while maintaining class G3 transient response performance. To satisfy these two requirements, the current work included a design study that used a 1D engine model and generator load model in combined to simulate step changes in load.

Figure 8 compares the results of the step change simulation for a twin-turbo engine with two comparatively large turbochargers (Figure 9(a)) and a quad-turbo engine in which the turbochargers have been downsized but the number has been increased to four to provide the overall system charged air capacity (Figure 9(b)).

The figure shows that the twin-turbo engine suffers from a severe drop in engine speed after the step change in load due to turbo-lag (the delay in the intake and exhaust response of the turbocharger). It also takes a long time for the speed to recover. In contrast, the quad-turbo engine experienced only a small drop in engine speed, indicating that it can respond rapidly to sudden increases in load.

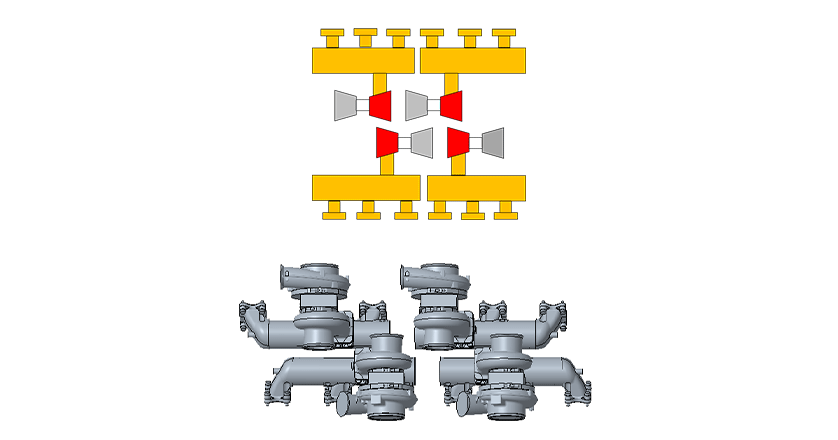

It is also known that the layout of the intake and exhaust system influences transient performance, including in quad-turbo engines. For example, the transient performance of the version B engine shown in Figure 10 is different from that of version A despite both having four turbochargers. This is due to effects such as exhaust interference. These effects were taken into account and simulation used to determine the optimal intake and exhaust layout that balances load response with other aspects of engine performance. The end result is that the 12GY175L achieves a high level of transient performance, sufficient to satisfy data center criteria for step changes in load.

4.4. Injection Optimization

The engine is equipped with a common rail fuel injection system with a maximum fuel injection pressure as 2200 bar.

Use of high-pressure multi-stage injection can reduce PM and NOX emissions and Yanmar has verified that the 12GY175L can comply both with Japan’s Air Pollution Control Act and with EPA Tier 2 (the world’s most stringent standard) without an exhaust gas after-treatment system.

This means that the engine can be sold around the world, not just in Japan.

Through the precise electronic control of fuel injection, the engine also does not generate any visible blue-white or black smoke on starting and achieves a level of fuel economy that places it among the best when compared to competing diesel engines.

5. Conclusions

This article has described the 12GY175L diesel engine and the technologies it uses. Acknowledging the increased demand for higher generator output that has come with the growth in data center size, Yanmar intends to expand the range of outputs it offers by producing engines with a larger number of cylinders.

Moreover, with the pursuit of net-zero greenhouse gas emissions in mind, work on adopting technologies for running engines on multiple different fuels is also underway.