Product Development Department

Development Division

YANMAR ENERGY SYSTEM CO., LTD.

YANMAR Technical Review

Commercialization of HP35FA1Z Stationary Hydrogen Fuel Cell Power Generation System

Compact, All-in-One System for Supply of Clean Power

Abstract

Yanmar has developed a stationary fuel cell power generation system, “HP35FA1Z,” with a power output of 35 kW, utilizing hydrogen as fuel to contribute to carbon neutrality. This product does not emit greenhouse gases such as carbon dioxide during power generation, thereby supporting our customers’ decarbonization efforts. Additionally, the HP35FA1Z is characterized by its compactness and flexible output control, while also ensuring reliability as a system. In this article, we will introduce the product concept of the HP35FA1Z and the Yanmar technologies applied to achieve its commercialization.

1. Introduction

Yanmar Energy System Co., Ltd. supplies generators and cogeneration systems that, in most cases, are powered by internal combustion engines. The need for these systems has been growing in recent years, being installed not only as business continuity planning (BCP) measures for dealing with power outages caused by earthquakes, typhoons, or other natural disasters, but also in distributed energy system applications where they are used to augment intermittent solar, wind, or other renewable energy generation.

Meanwhile, amid international recognition that preventing global warming calls for a transition from fossil to carbon-neutral fuels, and with the enactment in May 2024 of Japan’s Hydrogen Society Promotion Act, a growing number of initiatives are underway to achieve wider use of carbon-neutral fuels. These include demonstration projects involving the use of hydrogen that are planned for a variety of locations.

This article describes the HP35FA1Z hydrogen fuel cell power generation system developed by Yanmar in response to this changing environment.

2. HP35FA1Z Product Concept

The HP35FA1Z (shown in Figure 1) is primarily targeted at businesses or municipalities investigating the use of hydrogen as a source of clean energy. It is anticipated that such customers will want to use hydrogen fuel cells to augment intermittent renewable energy generation, thereby ensuring the reliable supply of CO2-free electricity regardless of the weather or the time of day. The system also has potential applications in off-grid power generation and as a means of improving disaster resilience. Accordingly, the system must be able to support a wide range of operating patterns, with seamless output control from low load up to rated power, load-following capabilities for dealing with sudden load swings or disconnection, and the ability to operate under a supervisory controller such as an energy management system (EMS). As cost and the practicalities of installation are often major issues when considering a system like this, the unit also needs to be compact and easy to install. Reliability and support availability are also vital given that the systems are used for the supply of electricity. Safety design, meanwhile, needs to take account of the fact that hydrogen is a new fuel with characteristics that include requiring less energy than natural gas to ignite and being a colorless and odorless gas, making leaks difficult to detect.

Based on these considerations, the following three features were chosen as the product concept for the HP35FA1Z.

① Load-based output control with an autonomous operation capability

② Compact, all-in-one system design

③ Reliable generation system operation and comprehensive support

3. Product Features and Technologies

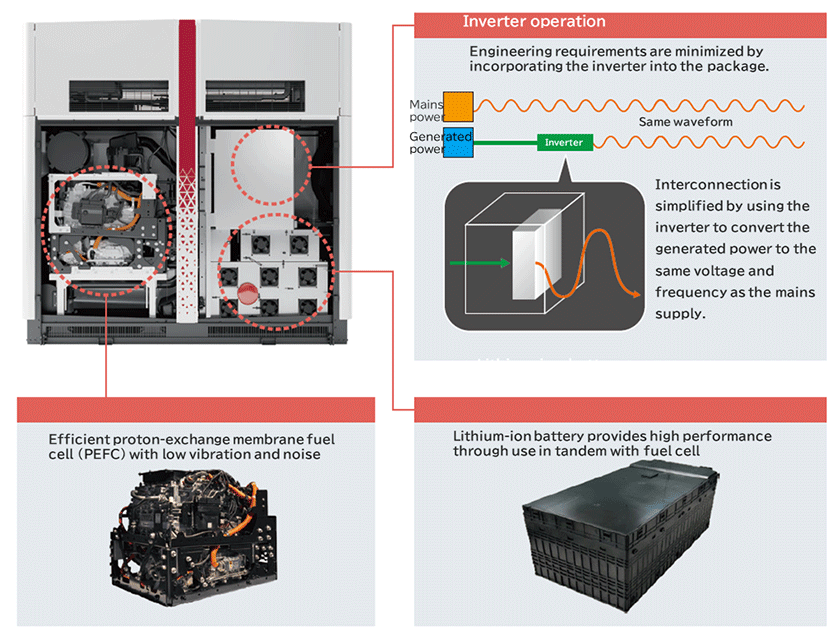

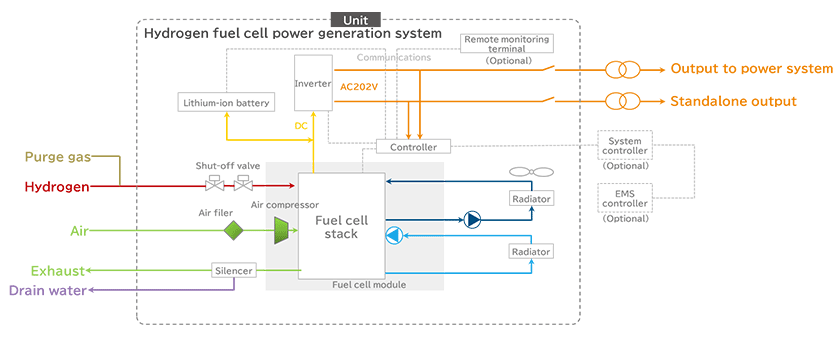

Figures 2 and 3 show the main system components and block diagram and Table 1 lists the specifications. The system combines a proton-exchange membrane fuel cell (PEFC) module with an inverter and lithium-ion battery. The inverter converts the direct current (DC) output of the fuel cell module to three-phase alternating current (AC) that can be output to the mains power supply or serve as a standalone power supply during a power outage. The lithium-ion battery is used to supply power when starting the fuel cell module, to store excess electricity during power outages, and for the output control function described later in this article.

The following sections describe the technologies used to implement the product concept features.

Table 1 HP35FA1Z Specifications

| Model | HP35FA1Z | |

|---|---|---|

| Rated output | Connected | 35 kW |

| Standalone | 35 kVA | |

| Frequency | 50 Hz / 60 Hz | |

| Output voltage and phases | Three-phase 202 V AC | |

| Fuel | Hydrogen (purity ≧99.97%) | |

| Generation efficiency*1 | 51.2% | |

| Power source | Proton-exchange membrane fuel cell (PEFC) | |

| Tandem operation | Up to 16 units (when connected to a power system) | |

| Dimensions | Width: 2,340 mm, Depth: 900 mm, Height: 2,290 mm | |

| Weight | 1,650 kg | |

- *1The generation efficiency value is based on the conditions specified in JIS C 62282-3-200:2019. The reference temperature and pressure are 288.15 K (15°C) and 101.325 kPa, respectively.

3.1. Load-based Output Control with Autonomous Operation Capability

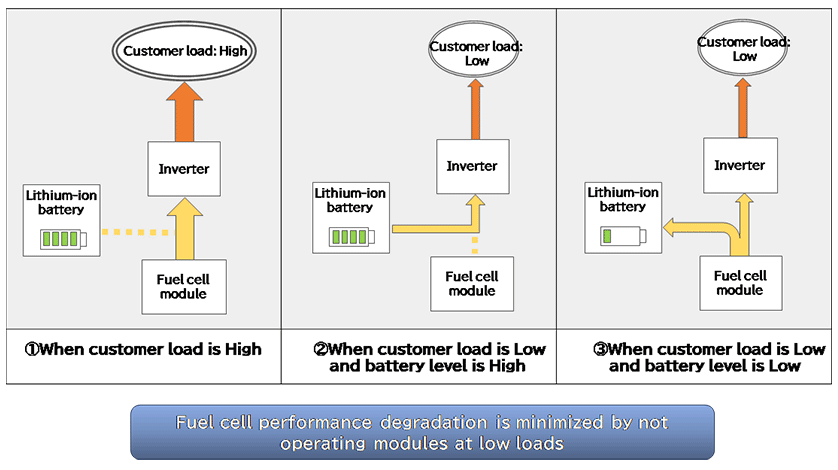

While the HP35FA1Z is mainly used for business or district electricity supply, where it operates as a distributed generation system that does not emit any CO2, its applications are also expected to include operation as a standalone electricity system that supplies the loads at a specific site during a power outage. Accordingly, the HP35FA1Z is equipped both with functions for grid-connected operation at rated output and the capability to vary its output over a wide range of loads. Unfortunately, frequent starting and stopping of a fuel cell tends to degrade its performance while operation at low load risks running up against the fuel cell module’s minimum output limit. For these reasons, additional measures were needed to enable these modes of operation.

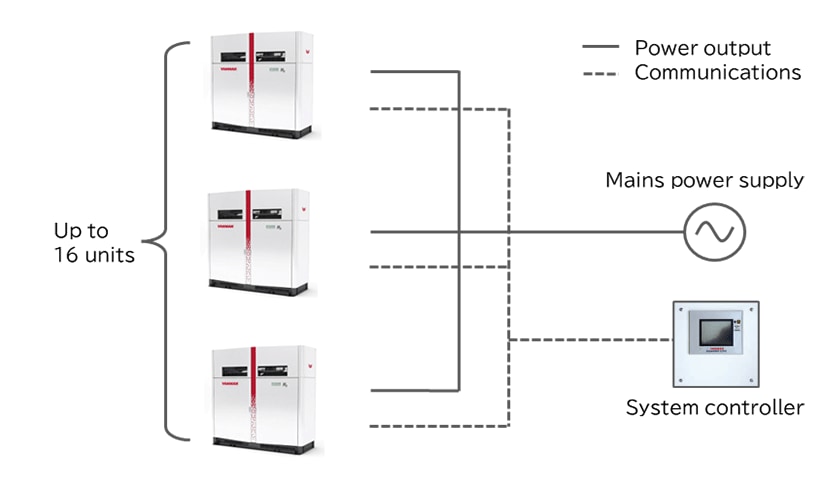

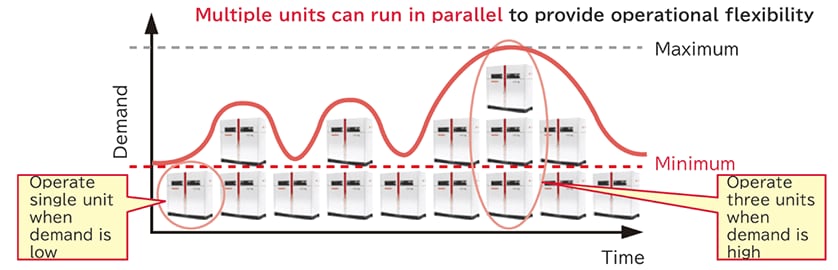

To overcome this problem, the HP35FA1Z is equipped with a lithium-ion battery in addition to its fuel cell module and uses hybrid operation whereby the control system switches to battery output when operating at low load (Figure 4). This enables the HP35FA1Z to minimize fuel cell performance degradation while still maintaining optimal output control across all loads. It also allows up to 16 units to be controlled in tandem by a single system controller, as shown in Figures 5 and 6, thereby providing optimal control of the number of operating units and total system output based on user electricity demand. Fuel cell degradation can be further minimized when operated in this tandem configuration through load balancing and rotation of the operating units to smooth their respective running times. The HP35FA1Z can operate in ways that suit customer needs, including functions for operating as part of a virtual power plant (VPP), microgrid, or other such service when connected to an EMS or other supervisory controller.

3.2. Compact, All-in-One System Design

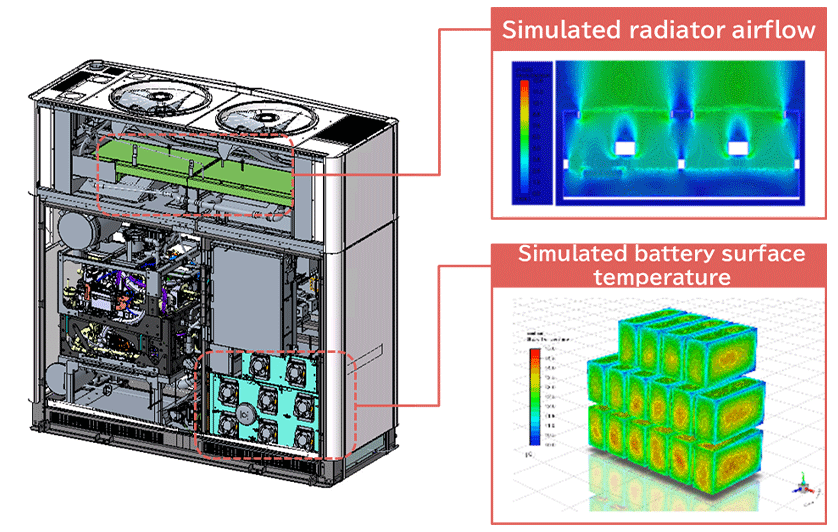

To reduce installation costs by minimizing the amount of on-site work needed to be undertaken by the customer, all the components required to operate the HP35FA1Z, including the fuel cell module, lithium-ion battery, and inverter, are housed in a single compact package. While the unit also includes a radiator to remove heat produced during power generation, this is made more difficult by the characteristics of PEFC cooling, which has an outlet water temperature of only about 70°C, closer to ambient temperature than the 90°C at which engine cooling water is typically discharged. The larger radiator necessitated by this was an obstacle to the goal of housing the unit in a compact package. To address this issue, Yanmar adopted a two-tier interior configuration to reduce the installation footprint, with the radiator on top and the fuel cell module and other electrical equipment on the bottom. This provided enough space for a large radiator. The practicalities of equipment transportation were also considered by installing the radiator horizontally rather than vertically, thereby keeping the height of the completed system to a minimum while still providing sufficient surface area for cooling. The air flows through the three components that require cooling (the radiator, fuel cell module, and electrical equipment) were also separated to ensure efficient cooling in each region. As shown in Figure 7, the ventilation design included system optimization in which computational fluid dynamics was used for simulation-based verification, including that the required air flow rates would be achieved and that component temperatures would remain within the target values.

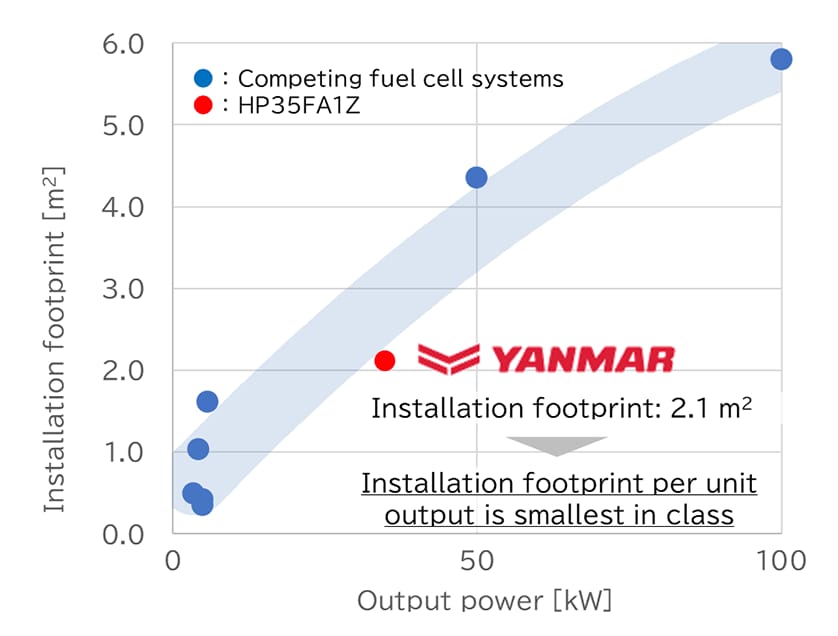

As a result of this work, the size of the HP35FA1Z package has been kept small with an installation footprint that is among the smallest for its product class, as shown in Figure 8.

3.3. Reliable Generation System Operation and Comprehensive Support

The HP35FA1Z uses automotive fuel cell modules that combine a high power-to-weight ratio with low cost. To enable its use for stationary power generation, Yanmar worked with the fuel cell vendor to verify that it complies with the laws governing this application and established practices to ensure that the required testing is performed during delivery inspection at the factory.

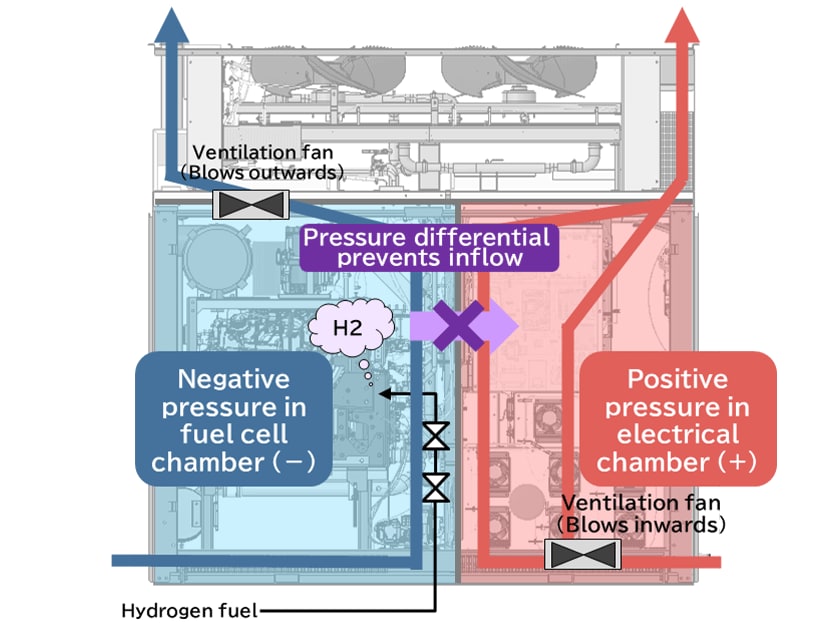

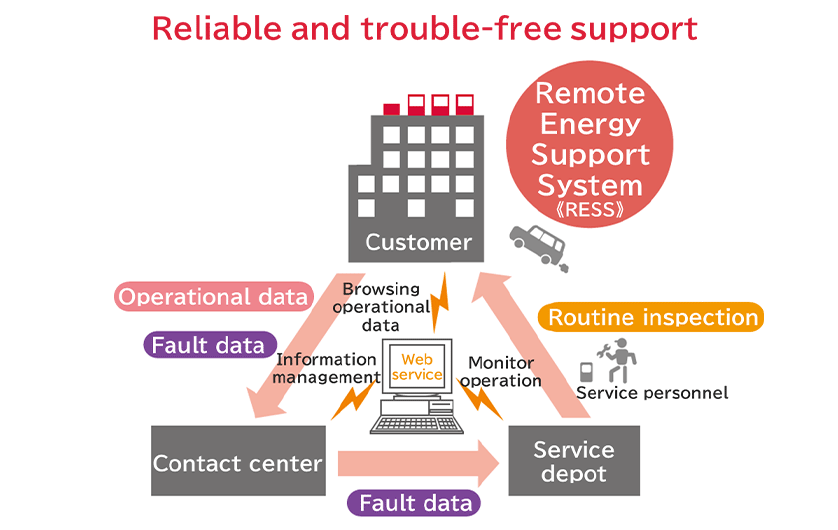

As noted earlier, the minimum ignition energy for hydrogen is lower than that of other fuels such as natural gas. Being a colorless and odorless gas, hydrogen leaks are also difficult to detect. This means that safety measures are needed to deal with any such leaks should they occur during operation. Not only does the HP35FA1Z system shutdown immediately and turn off the hydrogen supply on detection of a leak, but it also incorporates design features such as locating the ventilation fan in such a way that it maintains a pressure differential inside the system that prevents any leaked hydrogen from reaching or accumulating around electrical parts or other potential ignition sources (see Figure 9). Yanmar also provides a maintenance service using its Remote Energy Support System (RESS) (shown in Figure 10), with 24-hour/365-day operational data monitoring of its products and rapid support from local service staff in the event of a problem.

4. Delivery record

This section describes an example HP35FA1Z installation at JERA’s Sodegaura Thermal Power Station. The HP35FA1Z units at this site are paired with a photovoltaic power generation system with routine operation being controlled by a Yanmar EMS. The Yanmar EMS supplies CO2-free electric power and helps make energy use more efficient, being equipped with features for optimal control based on data such as electricity demand predictions.

5. Conclusions

As a carbon-neutral product that generates electricity without CO2 emissions, the HP35FA1Z hydrogen fuel cell power generation system described in this article can help customers in their efforts to decarbonize. As a leading energy systems company, Yanmar intends to continue supplying energy solutions that reduce greenhouse gas emissions and help customers overcome the challenges they face by offering decarbonization products that meet their needs.

Author